Bâche Géotextile - Staple Fibers Needle Punched Non Woven Geotextile with Best Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

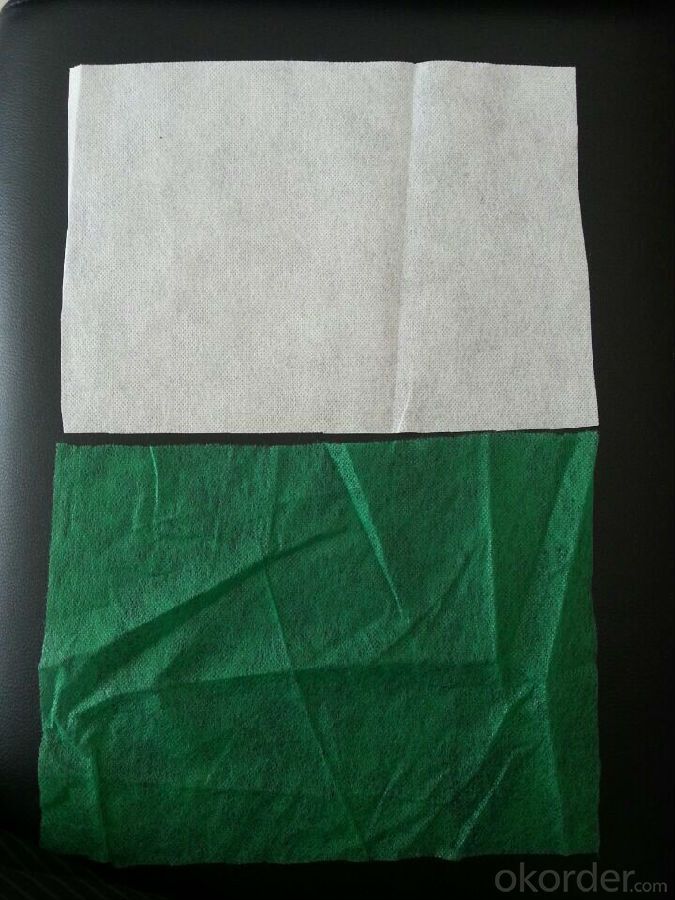

Staple fibers needle punched non woven geotextile

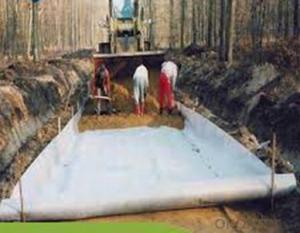

Filament geotextile mainly applied in water conservancy, road, railway, dam and tunnel for separation, filtration, reinforcement and drainage of projects

Features: It owns the advantages of acid and alkali resistance, erosion resistance, aging resistance, large strength, stable size, good filtrability etc.

Application: Mainly applied in water conservancy, road and railway for strengthening, separation, reversed filter and drainage of projects

Specification:100g~800g

Properties of Staple fibers needle punched non woven geotextile

Item | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | Note |

Mass error in unit area (%) | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | |

Thickness (mm) ≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

Error of width (%) | -0.5 | |||||||||||

Breaking strength (KN/m)≥ | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | MD/CD |

Elongation at break | 25~100% | |||||||||||

CBR puncture resistance (KN)≥ | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 | |

Equivalent Pore size O90( O95) | 0.07~0.2 mm | |||||||||||

Vertical permeability coefficient | K×(10-4~10-3)cm/s | K=1.0-9.9 | ||||||||||

Tearing strength (KN)≥ | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.60 | MD/CD |

Images of non woven geotextile

- Q: How do geotextiles help with waste containment systems?

- Geotextiles help with waste containment systems by acting as a barrier and providing reinforcement. They prevent the migration of waste materials, such as landfill leachate or contaminated soil, by effectively separating and containing them within the system. Geotextiles also enhance the stability and durability of the containment system by distributing loads and reducing the risk of punctures or tears.

- Q: Performance and Application of Impervious Geotextile

- Anti-seepage geotextile has excellent water permeability, filterability, durability, can be widely used in railways, highways, sports museum, dams, hydraulic construction, then hole, coastal beach, reclamation, environmental protection and other projects. Mainly staple acupuncture non-woven geotextile and split film woven geotextile. Anti-seepage geotextile function: 1. The use of geotextiles good permeability and water permeability, so that water through, so as to effectively remove the loss of sand. 2. Geotextile has a good water conductivity, it can form a drainage channel within the soil, the soil structure of the excess liquid and gas efflux. 3. Using geotextile to enhance the soil tensile strength and resistance to deformation, enhance the stability of the building structure to improve the quality of soil. 4. Effective focus will be concentrated diffusion, transmission or decomposition, to prevent soil damage by external forces. 5. to prevent the upper and lower gravel, soil and concrete mixed between. 6. Mesh is not easy to plug - due to the formation of amorphous fibrous tissue structure and strain and mobility. 7. High permeability - under the pressure of soil water, can still maintain a good permeability 8. Corrosion resistance - to polypropylene or polyester and other chemical fiber as raw materials, acid and alkali, no corrosion, no moth, antioxidant. 9. Construction is simple - light weight, easy to use, simple construction. Anti-seepage geotextile characteristics High anti-puncture strength, large coefficient of resistance to aging performance, to adapt to the environmental temperature range Excellent excellent anti-drainage performance for water conservancy, chemical, construction, transportation, subway, tunnel, garbage disposal and other projects

- Q: How do geotextiles contribute to the longevity of geosynthetic clay liners?

- Geotextiles contribute to the longevity of geosynthetic clay liners by providing a protective barrier between the clay liner and surrounding materials. They help to prevent the intrusion of fine particles, such as silt or sand, into the clay liner, which can compromise its effectiveness and lifespan. Additionally, geotextiles enhance the drainage capabilities of the clay liner, reducing the potential for water buildup and increasing its overall durability.

- Q: Polyester geotextile price how much

- Is there a scientific name? Added: Will not it be filament geotext? This is what we have, but the scientific name does not call you this!

- Q: Can geotextiles be used in riverbank stabilization applications?

- Yes, geotextiles can be used in riverbank stabilization applications. Geotextiles are commonly used to reinforce the soil and prevent erosion in riverbanks, helping to stabilize the slopes and prevent soil loss. They are effective in reducing water flow velocity, promoting vegetation growth, and providing long-term stability to the riverbank.

- Q: Can geotextiles be used in wetland restoration projects?

- Yes, geotextiles can be used in wetland restoration projects. Geotextiles, which are permeable fabrics made from synthetic materials, can serve multiple purposes in wetland restoration. They can be used to stabilize soil, control erosion, and filter sediment, while still allowing water and nutrients to pass through. By using geotextiles, wetland restoration projects can effectively manage water flow, enhance vegetation growth, and protect against erosion, ultimately aiding in the successful restoration of wetland ecosystems.

- Q: I'm looking for the fabric that goes between gravel and the ground (for a gravel driveway).

- any good irrigation/ landscape suply house will have that material.

- Q: Such as the title, the drawings are written on the weaving geotextile, the list is written on the blended geotextile cloth laying / 120g / m2 weaving geotextile, who can tell ah !!!!!!!!!! Urgent more

- Weaving geotextile cloth, also known as woven geotextile, and non-woven geotextile is not the same, the technical requirements between them are not the same. Light to see the material name sometimes can not determine the material, mainly to see the technical data, if you want to know more about it can add me

- Q: How do geotextiles help with erosion control in riverbanks?

- Geotextiles help with erosion control in riverbanks by acting as a barrier and stabilizing the soil. They prevent the soil particles from being washed away by the flowing water, while still allowing water to pass through. This helps to reduce the velocity of the water, minimizing the impact of erosive forces and protecting the riverbank from further degradation.

- Q: Polyester geotextile filter layer sets what the amount

- Polyester filament geotextile Features: Polyester filament geotextile is made by polyester method by spinning acupuncture consolidation directly made, product specifications from 80-800g / m2 arbitrary choice, it is geotechnical engineering and civil engineering In the application of a geosynthetics, polyester filament into a network and consolidation method, the fiber arranged in three-dimensional structure. In addition to good mechanical properties, but also has a good vertical and horizontal drainage performance and good extension properties and high resistance to biological, acid and alkali, anti-aging and other chemical stability. At the same time, it also has a wide pore size range, tortuous pore distribution, excellent permeability and filtration performance. Polyester filament geotextile Uses: water conservancy project dam and slope protection of the filter, channel isolation, seepage; road, rail, airport runway foundation isolation, filter, drainage, slope, retaining wall and road reinforcement, Drainage; Port Engineering soft foundation treatment, traces of the tube of the river alone sweeping the beach embankment, harbor wharf and breakwater reinforcement, drainage; polyester filament geotextile has been widely used in the field of infrastructure construction, and gradually applied In a wider area.

Send your message to us

Bâche Géotextile - Staple Fibers Needle Punched Non Woven Geotextile with Best Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords