Bassin Géomembrane High Strength Road & Landfill Constructions Tri-Dimension Compound Geonet for Drainage, Filtration

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

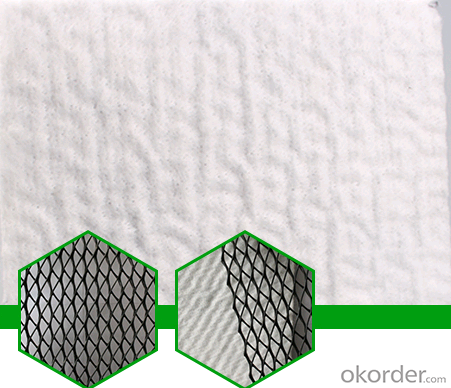

Tri -dimension composite geonet / geonets and geocomposites

Be made of tri-dimension geonet coated geotextile on both sides, has the property of geotextile (filtration) and geonet (drainage and protection), and has the complete function of "filtration--drainage-- protection"

Application

landfill drainage

hignway roadbed

railaway drainage

tunnel drainage

underground structure drainge

retaining walls drainage

garden and playground drainage

Feature

- stronger drainage function and can bear high press load for a long time

- high tensile strength and shear strength

- keep stable water conductivity

- can bear compression load of more than 2000kpa

- larger anti-compression capacity than common geonet

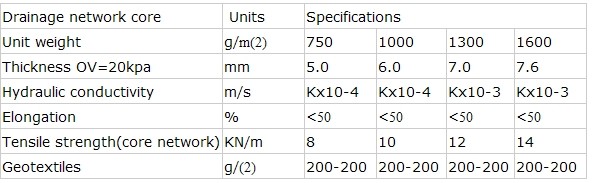

Tri-dimension composite geonet technical specifications

- Q: What are the prospects of electrothermal?film?

- Electrothermal film has been in the market for at least ten years. Currently the biggest problem is the large power consumption, even if you can cover the electric charge,original home wire diameters restrict the use of high-power electrical appliances. Another problem is power attenuation, the other problem is breaker tripping caused by electric leakage.

- Q: Can geomembranes be used in decorative swimming pools and water features?

- Yes, geomembranes can be used in decorative swimming pools and water features. Geomembranes are impermeable liners that can effectively prevent water leakage and provide a reliable barrier. They are commonly used in various applications, including decorative pools and water features, to ensure water containment and prevent seepage into the surrounding soil.

- Q: What are the common applications of geomembranes?

- Geomembranes have a wide range of common applications, including use in landfill liners, pond and canal liners, mining and oil containment, water storage and treatment facilities, and agriculture and aquaculture operations. They are also used for environmental protection, such as in preventing soil erosion and contamination.

- Q: Can geomembranes be used for gas containment?

- Yes, geomembranes can be used for gas containment. Geomembranes are impermeable liners that are commonly used to prevent the migration of fluids, including gases, in various applications such as landfill sites, storage tanks, and anaerobic digesters. They provide an effective barrier to prevent gas leakage and can be designed to withstand the pressure and chemical properties of different gases.

- Q: What are the technical points of the lioghtweight foam?concrete?

- 1. To clean the surface and ensure that there is no dust and dirt of the grassroots, for smooth, solid, light pressure, does not allow rugged, loose and sand off ash and other defects. 2. To make a good preparation of the materials, the foaming agent, additives, cement and auxiliary materials should be transported to the designated place for storage. 3. It should be leveled according to the design. First, take use of the cement mortar according to 2.5x2.5m to determine the height of the slope. 4. To start the foaming machine to start to work, and then start the host. To sent the cement into the agitator with the help of the conveyor?belt/band carrier. And after it is mixed uniform to start the transportation system of foam conveying system and high-pressure pump. And then mix the concrete composite material averagely and transport them to the disignated construction area to cast. 5. According to the requirements of the construction, the professionals will smooth the castin foam concrete. (with help of the smooth floating ruler) Because after it is being smooth, the surface of the foam cement will produce a little air void which will have a bad effect of the surface of the waterproof construction. It is suggested to establish the 70% final set of the casting foam concrete and use the cement mortar to smooth and protect. 6. When the integral casting of foam concrete has reached 4000 square meters and the final set of the concrete has up to 70%( It is generally 25 centigrade and 36 hours). The cut of the dividing joint should be in time. And the width of the dividing joint should be bigger than 4x4m. The the width and depth of cutting of every dividing joint should be calculated by 1/800 telescopic value of the thermal efficiency expansion. The deepth of the width of cutting is 1.5x3.0cm, the elastic sealing material will be sealed in after the cutting.

- Q: HDPE geomembrane related

- HDPE geomembrane in the anti-seepage construction quality inspection method 1: laying anti-seepage membrane should be civil engineering corresponding to the corresponding acceptance of documents. 2: anti-seepage film before cutting, it should accurately measure the relevant size, and then according to the actual cutting, generally should not be cut according to the size of the figure, should be piece by piece number, detailed records in the special form. 3: laying impermeable membrane should try to weld at least, in ensuring the quality of the premise, as far as possible to save raw materials. But also easy to ensure quality. The lap width of the joint between the membrane and the membrane is generally not less than 10 cm, usually in the direction of the weld arrangement parallel to the maximum slope, that is, along the slope direction. 4: usually in the corner and the deformity of the lot should be shortened in length. In addition to the special requirements, in the slope of more than 1: 6 on the slope from the top of the slope or stress concentration area of 1.5 meters, as far as possible without weld.

- Q: what's the distinguish between geomembrane and waterproof board?

- Basements and tunnels; tailing dam, rockfill dam; waste storage; construction cofferdam; m2-800g & # 47; channels: Membrane thickness from 0: anti-seepage, isolation purposes, waste water reservoir dam and reservoir area, tunnel anti-seepage lining: Geotechnical dam, highway: 4-6-meter: Two cloth one membrane (both sides of the impermeable membrane are added with protective geotextile) one cloth one membrane (one side of impermeable membrane is added with protective geotextile) width, railroad embankment .8mm protective layer of geotextile from 100g & # 47.2mm - 0; roadbed and other foundation saline control, masonry dam and concrete dam development pressure; leakproof roofing product features; roads, Khouang); dike, reservoir tank (pit; underground; expansive soil and collapsible loess waterproof layer, dam levels impervious blanket, ground vertical impermeable layer

- Q: How do geomembranes contribute to energy efficiency?

- Geomembranes contribute to energy efficiency in several ways. Firstly, they act as barriers to prevent the transfer of heat or cold, reducing the need for heating or cooling systems. This helps to maintain a consistent temperature inside buildings, leading to lower energy consumption and costs. Secondly, geomembranes can be used as liners for energy storage systems such as geothermal energy or solar ponds. These liners prevent the loss of heat or energy, maximizing the efficiency of these systems. Additionally, geomembranes are often used in the construction of energy-efficient buildings. They can be incorporated into insulation systems, preventing air leakage and improving thermal performance, thus reducing the energy required for heating and cooling. Overall, geomembranes play a crucial role in reducing energy consumption and improving energy efficiency in various applications, from building construction to energy storage systems.

- Q: How to make geomembrane inspection?

- First laying: Overall consideration of reducing the seams and convenient construction, selecting the composite geomembrane of appropriate width, with single-sided margin of 10cm and neat scrapped edge. The debris on the ground should be cleaned up and the size, flatness and compactness of slope cutting site should be subject to the acceptance of supervising engineer before laying the geomembrane. Connection: Usually using sweat soldering method

- Q: Can geomembranes be used in biogas production facilities?

- Yes, geomembranes can be used in biogas production facilities. They provide an effective solution for the containment and storage of biogas, preventing its release into the atmosphere. Geomembranes are used to line the anaerobic digesters, tanks, and storage facilities, ensuring the integrity and durability of the structures. They help to maintain a controlled environment for the biogas production process and minimize the risk of leakage, contamination, or odor nuisance.

Send your message to us

Bassin Géomembrane High Strength Road & Landfill Constructions Tri-Dimension Compound Geonet for Drainage, Filtration

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords