ASTM Z80 Prepainted Galvanized Rolled Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 26000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

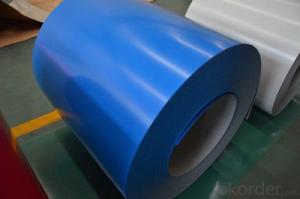

Structure of ASTM Z80 Prepainted Galvanized Rolled Steel Coil

Description of ASTM Z80 Prepainted Galvanized Rolled Steel Coil

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of ASTM Z80 Prepainted Galvanized Rolled Steel Coil

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of ASTM Z80 Prepainted Galvanized Rolled Steel Coil

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of ASTM Z80 Prepainted Galvanized Rolled Steel Coil

Product | Prepainted Rolled steel Coil for Construction Roofing |

Material Grade | SGCC / SGCH / DX51D+Z, etc |

Thickness | 0.3-4.0mm |

Width | 400-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of ASTM Z80 Prepainted Galvanized Rolled Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each color. And we could give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your can offer the better price we can provide.

2. How long can we receive the product after purchasing?

Usually within thirty working days after received buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15- 25 days, but the shipment will depend on the vessel situation.

3.What kind of terms of payment?

T/T, L/C,D/A,D/P,Western Union are available.

- Q: How are steel coils used in the production of agricultural systems?

- Due to their durability and strength, steel coils are frequently employed in the production of agricultural systems. Specifically, these coils are commonly utilized in the creation of machinery and equipment essential for agricultural operations. One prevalent use of steel coils lies in the manufacture of farming machinery such as tractors, plows, and cultivators. These machines necessitate robust components capable of enduring the challenging conditions present in the agricultural environment. Steel coils are employed to fabricate the frames, chassis, and other structural parts of these machines, providing the necessary strength and support. Additionally, steel coils are employed in the creation of irrigation systems, which play a crucial role in efficient water management within agriculture. These coils are employed in the construction of pipes, valves, and fittings, ensuring the durability and long-lasting nature of the irrigation system. Furthermore, steel coils are employed to fabricate storage tanks and silos, which serve as vital tools for storing and preserving agricultural products like grains, seeds, and fertilizers. Moreover, steel coils find application in the construction of greenhouses and agricultural buildings. These coils are used to fabricate the structural framework, providing stability and resistance against environmental factors. Steel coils are also employed in the production of fencing and enclosures to safeguard crops and livestock from external threats. In conclusion, steel coils play a significant role in the production of agricultural systems by delivering the necessary strength, durability, and stability required for farming machinery, irrigation systems, storage facilities, and agricultural structures. Their utilization ensures that these systems can withstand the demanding conditions of the agricultural industry and contribute to efficient and sustainable farming practices.

- Q: i am working in a firm that deals with steels.. so it is necessary for me to understand the chemistry of the steels from their names so that i need not memorize all the grades with their metallury.. where can i find information about this nomenclature ? please help

- For steels with a four number code like 1020, 4140 ect the first two digits are the alloying information. I think you need to memorise those. 10 steels are plain carbon steel with no alloying. 41 steels are chrome-molly. The third and forth digits are the carbon content. 1020 is 0.2% Carbon, 4140 is 0.4% carbon. I don't know if there is a system to stainless steels.

- Q: I want to make an object out of stainless steel. Initially, I had planned to get it cut out of stainless steel sheet but several of the edges need to be rounded and I think it would be much cheaper to get it made of cast iron formed in a mold.Yet, it must be stainless steel. Can stainless steel be formed in a mold like iron can ... i.e. poured in liquid form into a mold and harden into shiny stainless steel?Would a regular foundry do this or do I need something special?Thanks.

- You have 2 options. Sand casting or investment casting. Stainless steel can be cast with either of these methods. In either case a model or pattern will have to be created. For sand casting the pattern is all that is needed to go to casting. For investment casting the pattern is used to make a wax casting, which is then coated with the investment. The wax is burned out and the metal is then poured into the cavity. If you are making just 1 or 2 pieces you can have waxes machined. This saves the intermediate step Depending on the size machining may still be your best option. Especially if you want just 1 part.

- Q: How are steel coils processed for cutting to length or blanking?

- Steel coils are typically processed for cutting to length or blanking through a series of steps. First, the coils are unwound using a machine called an uncoiler, which feeds the steel into the cutting process. Then, the steel passes through a leveler to ensure a flat surface. Next, it enters a shear or blanking process, where the steel is cut into desired lengths or shapes. Finally, the cut pieces are stacked or packaged for further use or distribution.

- Q: PLS tell me all Foam Steel Characteristics and use?Thanks

- Foam steel [often steel foam] is used in applications that require light weight but high rigidity and strength. Watertight doors on modern ships are often made of foam steel. Pressure doors on aircraft are possible uses. As we keep striving for lighter weights in cars, foam steel might have some useful applications in bodies. There is a technical paper online that is in .pdf format that has a good discussion of the process and characteristics of foam steel.

- Q: How are steel coils used in the production of steel containers?

- Steel coils are an essential component in the production of steel containers. These coils, made from flat-rolled steel, are used to create the main body of the container. Firstly, the steel coils are unwound and fed into a rolling mill, where they undergo a series of processes to shape and form the steel. This includes heating the coils to a specific temperature to make them more malleable and easier to work with. The hot coils are then passed through a series of rollers that gradually reduce their thickness and lengthen them to the desired size. This process is known as hot rolling. Once the steel coils have been rolled to the required thickness, they are then cooled and cut into sheets. These sheets are then further processed to remove any imperfections or irregularities, ensuring a smooth and uniform surface. This is done through processes such as pickling, where the sheets are treated with acid to remove any scale or rust, and cold rolling, where the sheets are passed through rollers at room temperature to achieve the desired thickness and surface finish. After the sheets have been cleaned and smoothed, they are then formed into the shape of the container. This is typically done through a process called stamping, where the steel sheets are pressed into a mold using a hydraulic press. The mold determines the shape and size of the container, and the steel sheets are pressed against it with immense force, resulting in the desired container shape. Once the containers have been formed, they undergo various finishing processes such as welding, painting, and coating to enhance their durability, appearance, and resistance to corrosion. These final touches ensure that the steel containers are of high quality and meet the required standards for their intended use. In summary, steel coils play a crucial role in the production of steel containers by providing the raw material from which the containers are formed. Through a series of processes, the steel coils are shaped, cut, and formed into sheets, which are then further processed and transformed into the desired container shape. The result is a durable and reliable steel container that can be used for various applications across industries.

- Q: What are the different types of steel coil storage locations?

- There are various types of steel coil storage locations, including open yards, covered warehouses, coil racks, and specialized coil storage systems.

- Q: What is steel made of and what is its molecular weight? It's for a project in chemistry class so if you have a website link as well, that would be great!

- Steel is an alloy consisting mostly of iron with a little Carbon thrown in. Steel is not a molecule, therefore, it does not have a molecular weight. Steel contains atoms of iron and carbon in a crystal lattice, along with various other alloying elements such as manganese, chromium, vanadium, and tungsten.

- Q: How are steel coils used in the manufacturing of bridges?

- Steel coils are used in the manufacturing of bridges as they provide the raw material for creating structural components such as beams, girders, and columns. These coils are processed and shaped into the required sections, which are then assembled and welded together to form the bridge's framework. The strength and durability of steel make it an ideal material for constructing bridges that can withstand heavy loads and harsh environmental conditions.

- Q: density of mild steel (MS) is 7850 KG per metre cube , but i want to know the density of stainless steel

- Stainless steels are the most dense, coming in at 8000 kg/m3. Though the densities vary, The answer is 8000 kg/m3. 301 stainless density values seem to vary according to the supplier data sheets, from 7.88 g/cc, (AK Steel) to 8.03 g/cc, (Allegheny Ludlum)

Send your message to us

ASTM Z80 Prepainted Galvanized Rolled Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 26000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords