cold rolled stainless steel coil

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

stainless steel coil

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely used in light industry,heavy industry,daily necessities and the decoration industry.my company long term supply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube.

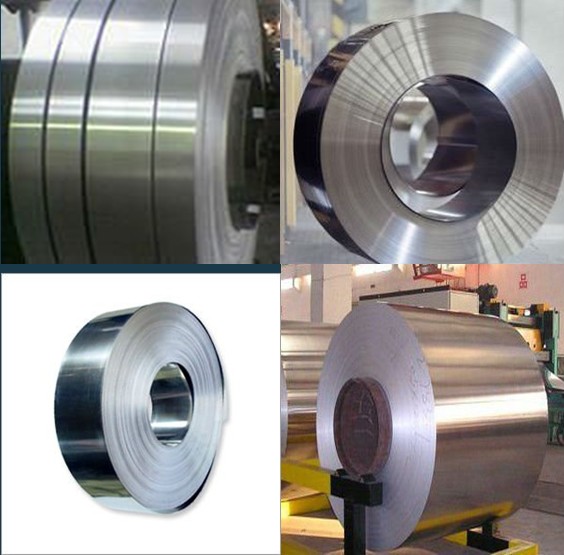

Article | stainless steel coil |

Specification | 1m 1.219m 1.5m or as your requirement |

Surface | 2B NO.1 BA Hairline 4K 6K 8K No.3 No.4 |

Type | coil |

Thickness | 0.3-3mm |

Brand | TISCO JISCO LISCO and so on |

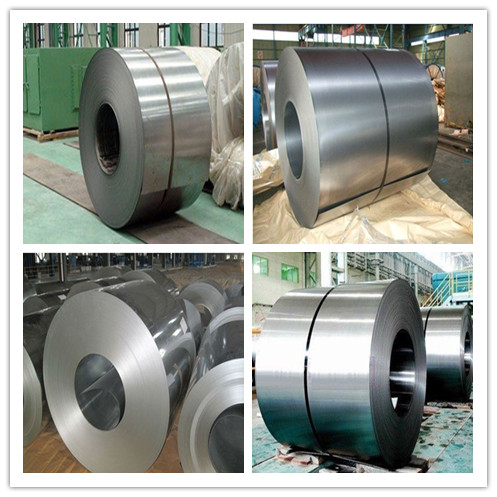

Application | Foodstuff,gas,biology,metallurgy,electron,chemical,petroleum,boiler,nuclear energy, equipment fertilizeretc and so on |

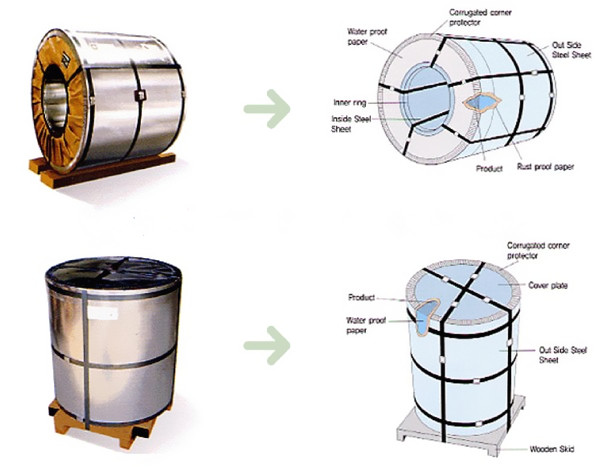

Parking | Waterproof paper, steel strip packed, wooden case,or as customers's requirement |

Payment | Small quantity (within total $20000.00) T/T at sight, 30% in advance , 70% after receiving the B/L Large quantity : L/C at sight |

container size | 20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High) |

Delivery Time | 15 days after received the deposit of T/T or L/C |

Note | We can produce other standard as the customers’s requirement |

A series of pictures

- Q: Should I stick with the all steel kit over the acrylic tapers and steel plugs? or would the acrylic be ok? I keep hearing that steel is the best and acrylic can cause problems. I just want to do it correctly and take my time with it, no rushing.thanks

- It depends on your body and what you prefer. If you body is allergic to one of them you would have to chose for another one. If it's not allergic to any, than you can use whatever you like the most, just try both.

- Q: How are steel coils used in the production of bridges and infrastructure?

- Steel coils are indispensable in the manufacturing of bridges and infrastructure. Made from sturdy and long-lasting steel, these coils can endure heavy loads and harsh environmental conditions. When constructing bridges, steel coils are utilized to produce structural elements like beams, girders, and columns. These components offer the necessary strength and support to the bridge, enabling it to bear the weight of vehicles, pedestrians, and other loads. The steel coils are shaped through rolling, cut to the required length, and then welded or bolted together to form these structural elements. Moreover, steel coils are also employed in the creation of bridge decks, which serve as the roadways or walkways on the bridge. These coils are processed into steel plates, which are then assembled and secured onto the bridge structure. The steel plates provide a smooth and durable surface for vehicles and pedestrians to traverse. Regarding infrastructure, steel coils play a crucial role in the construction of various structures such as buildings, stadiums, and industrial facilities. They are utilized to fabricate primary support systems, including columns, beams, and trusses, which furnish the necessary strength and stability to these structures. Steel coils are also used to manufacture roofing and cladding systems, ensuring protection against weather elements and enhancing the overall aesthetics of the infrastructure. Furthermore, steel coils frequently contribute to the production of reinforcing bars, commonly known as rebar. Rebar is essential for strengthening concrete structures like foundations, walls, and slabs. These coils are processed into different sizes and shapes, and subsequently embedded within the concrete to enhance its tensile strength and prevent cracking or collapsing under heavy loads. In conclusion, steel coils are a vital component in the manufacturing of bridges and infrastructure. Their strength, durability, and versatility make them an ideal material for constructing secure and dependable structures that can withstand the test of time.

- Q: What are the common coil surface treatments?

- The common coil surface treatments include galvanization, painting, and powder coating.

- Q: I have a set of Ben Hogan Apex Plus Forged Irons, how can i figure out if the shafts are steel or graphite?

- Hold one club in each hand and hit them together like swords fighting, putting the impact point about midway down each shaft, and listen to the sound. If it's more of a clank sound, it's steel, and more of a click sound, it's graphite.

- Q: What are the common coil loading and unloading techniques?

- The common coil loading and unloading techniques include using cranes or forklifts to lift and move the coils onto trucks or storage racks. Another technique is using coil transfer cars or coil handling equipment to transport the coils within a facility. Additionally, some facilities utilize coil upenders or turnstiles to rotate the coils for easier loading and unloading.

- Q: A roll of 1 meters wide color steel roll about how many tons?

- Color steel roll is a composite material, both steel and organic materials, both of them a little. Both the mechanical strength of steel plate and easy molding performance, but also organic materials, good decoration, corrosion resistance. 1 meters wide should also have length, wall thickness conditions to know how many tons. The manufacturer is generally in accordance with customer requirements into a volume, the normal width of 1 meters per roll over 1 tons.

- Q: Heard some steel companies like TATA Steel and JSW are in good performance. can some one suggest me if its good time to invest in steel industry ?

- To be blunt, with the Environmental-Terrorists like Green Peace and The Sierra Club making it basically impossible for Steel Production in the US to be a profitable industry, you are better off investing in Chinese Steel Companies than American. Same goes for Electricity Production and Petroleum Refining... These Environmental Terrorist Organizations and their misguided leftist followers have made it impossible to build new refineries in the US, which is why the price of Diesel Fuel is so much higher than unleaded, which is not only insane since Diesel Fuel actually requires LESS processing to be a viable product but also because our Transportation Industry as a whole relies upon Diesel Fuel to get everything in your home and office from manufacturer to store. By keeping the Energy Industry held hostage to these irresponsible and, to be blunt, insane laws, they have caused a rise in the price of EVERYTHING sold in the United States... From a deck of cards to homes. If we were not basically banned from building new Nuclear Reactors, we could cut our dependance on Coal by at least half... Anything having to do with any industry that could even potentially do with Pollution, regardless of how far advanced the technology has advanced away from that, it is restricted by Eco-Terrorists and mindless sheep that spend too much time listening to propaganda rather than fact checking what their Masters spoon feed them.

- Q: What are the different methods of slitting edge trimming for steel coils?

- There are several different methods of slitting edge trimming for steel coils, each with its own advantages and applications. 1. Rotary Shear Slitting: This method involves using rotary knives to cut through the steel coil. The knives are mounted on a rotating shaft and create a shearing action as they pass through the coil. Rotary shear slitting is a versatile method that can handle a wide range of coil thicknesses and materials. It is commonly used for high-volume production and provides a clean and precise cut. 2. Crush Cut Slitting: In this method, the steel coil is pressed against a hardened anvil by a rotating knife. The knife cuts through the coil by crushing it against the anvil. Crush cut slitting is suitable for thinner gauge materials and is often used for materials that are sensitive to shearing forces. It provides a clean cut but may have limitations in terms of coil thickness and width. 3. Razor Slitting: Razor slitting involves using a razor blade to cut through the steel coil. The blade is mounted on a rotating shaft and creates a slicing action as it passes through the coil. Razor slitting is commonly used for thin and delicate materials that require a precise and burr-free edge. It provides a clean cut but may have limitations in terms of coil thickness and width. 4. Shear Slitting: This method involves using a pair of opposing blades to shear through the steel coil. The blades move past each other to create a scissor-like cutting action. Shear slitting is commonly used for heavier gauge materials and provides a clean and precise cut. It is suitable for high-speed production and can handle a wide range of coil thicknesses and materials. 5. Laser Slitting: Laser slitting utilizes a high-powered laser beam to cut through the steel coil. The laser beam is guided by computer-controlled optics to create a precise and clean cut. Laser slitting is suitable for a wide range of coil thicknesses and materials, including high-strength steels. It provides a high level of accuracy and can handle complex cutting patterns. Each of these methods has its own advantages and considerations, depending on the specific requirements of the steel coil slitting operation. Factors such as coil thickness, material type, desired edge quality, and production volume will influence the choice of slitting method.

- Q: I am building a steel type competative team. my team so far isempolem, skarmory , Metagross, magnezone, lucario, ferrothorn.

- Good choice in pokemon. As for moves and EVs and all that... its kinda up to how exactly you wanna play your steel team, but heres what I can think up off the top of my head: Empoleon: Mixed Attacker. Swords Dance and Aqua Jet for strong priority attacking, with two special attacks (preferrably one water and one other non steel non water attack) Skarmory: Physical wall. Skarmory is know to be an amazing physical wall. So pump HP and defense EVs into it. Impish nature is best, and try to get Roost, Whirlwind, and Brave Bird on it. Stealth Rock or Spikes for entry hazard damage. Metagross: Physical attacker. Bullet Punch is nice since Metagross is kinda slow, and Hammer Arm is decent since it hardly cares about a speed drop. Earthquake and Zen Headbutt aren't bad either. Magnezone: Bulky Special Attacker. The teams a really physical one, so having a special attacker is nice so other physical walls don't mess you up too bad. Its main attacking moves should be Thunderbolt and Flash Cannon. Sturdy and Magnet Pull are both good abilities, which one you go with is up to you. Lucario: Physical Sweeper. Max out Lucario's Attack and Speed EVs, its defenses are too low for it to take repeated hits. Close Combat and Extremespeed are Lucario staples. The other 2 moveslots depend on you. An elemental punch is good for coverage. Earthquake... is Earthquake, its good to have. There's other options too. Ferrothorn: Ferrothorn has a number of options, usually involving its great bulk. Look this one up on Smogon. Other good steel types would include: Bronzong, Scizor, Forretress. Excadrill is good, but its far better in a sandstorm team than on an all steel team (Sand Rush+Swords Dance+Focus Sash+Attack=death). Hope this helps.

- Q: How do steel coils contribute to the construction equipment industry?

- The construction equipment industry relies heavily on steel coils as they are vital for manufacturing various construction machinery and equipment. These coils, made from high-quality steel, are crucial components used in the fabrication of a wide range of construction equipment, including cranes, bulldozers, excavators, loaders, and forklifts. The main contribution of steel coils to the construction equipment industry lies in their structural strength and durability. Steel is renowned for its exceptional mechanical properties, such as high tensile strength, toughness, and resistance to wear and corrosion. These properties make it an ideal material for constructing heavy-duty machinery capable of withstanding the demanding conditions of construction sites. Steel coils are employed in the production of the structural components of construction equipment, such as chassis, frames, booms, buckets, and attachments. These components need to be sturdy and able to endure heavy loads, impacts, and continuous use. Steel coils provide the necessary strength and reliability to ensure the long-lasting performance of construction equipment. Moreover, steel coils are also used to manufacture specialized parts and accessories for construction machinery. These include hydraulic systems, gears, shafts, bearings, and fasteners. These components are essential for the proper functioning and efficiency of construction equipment, and steel coils provide the high-quality material required for their production. In addition to their mechanical properties, steel coils also contribute to the construction equipment industry through their versatility and customization options. Steel can be easily shaped, cut, welded, and formed into various sizes and shapes, allowing manufacturers to create equipment with specific designs and functionalities tailored to meet the diverse needs of construction projects. Overall, steel coils are indispensable in the construction equipment industry as they serve as the foundation for robust and reliable machinery. Their strength, durability, and versatility make them an essential raw material for manufacturing construction equipment that can withstand the challenges of construction sites and ensure the safety and efficiency of construction projects.

Send your message to us

cold rolled stainless steel coil

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords