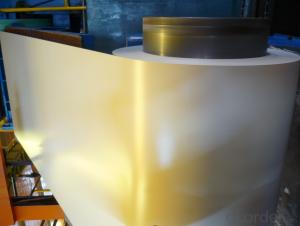

ASTM A653 PPGI Prepainted Galvanized Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Color Coated Galvanized Steel Coil

ISO System

SGS and BV Audited company

Industry experience over 10 years

Management Systems-Internal Software

Finished Product Inventory-More Than 500 Tons

Raw Material inventory -Over 800 Mertic Tons

Shipment of goods -More than 30 countries worldwide

We have the most convenient transport and prompt delivery

We offer competitive price with best service

We have high technical production line with top quality products

We have win high reputation based on best quality products

Product Description

PPGI:

1, Introduction: Color coated steel coils(sheets), i. e. PPGI, also called prepainted steel coils(sheets), are made of galvanized steel coils(sheets) with polymer coatings as surface. It's a new enclosure material and building board with characteristics of light-weighted, heat preserved&insulated, easily installed with bright colors.

2, Production Process: Pretreatment(Degreasing)_Drying_Chromating_Paint Basic Oil_Cooling_Drying_Color Coating_Cooling_Film-covering_Rolling Up

3, Characteristics:

Good at corrosion resistence. Besides zinc coating of the basic plate of galvanized steel sheet, the color coating as the surface has double lifetime to ensure better anticorrosion effect.

with excellent cold bending molded manufacturablity, PPGI products can be processed or directly used as final product. As being light-weighted and conveniently transported, they're widly used to replace wood to save energy.

There're thousands of colors can be chosen as per different application. Any color plays well in decoration.

No pollution with high recycling rate, PPGI coils and sheets are strongly recommended as enviroment-friendly products by the government.

4, Appliance: Thanks to the above characteristics, color coated steel coils and sheets are widly used in construction, furniture industry, transportation industry, ect.

5, eye bands and 4 circumferential bands in steel, galvanized metal fluted rings on inner and outer edges, galvanized.

| Type of substrate | Grade of color plate | Standard | Application& feature |

| Hot dip galvanized plate | TDC51D+Z | DC51D+Z | ordinary use |

| TDC52D+Z | DC52D+Z | SPCD | |

| TDC53D+Z | DC53D+Z | SPCE | |

| TS280GD+Z | TS280GD+Z | Structure use | |

| TS350GD+Z | TS350GD+Z | Structure use | |

| TS550GD+Z | TS550GD+Z | High strength structure use | |

| Hot dip galvalume plate | TDC51D+AZ | DC51D+AZ | ordinary use |

| TDC52D+AZ | DC52D+AZ | SPCD | |

| TS250GD+AZ | S250GD+AZ | Structure use | |

| TS300GD+AZ | 300GD+AZ | Structure use | |

| TS350GD+AZ | 350GD+AZ | Structure use | |

| TS550GD+AZ | 550GD+AZ | High strength structure use |

| Type of coating process | Front:double coated&double drying Back: double coated&double drying, single coated&double drying |

| Type of substrate | Hot dip galvanized,galvalume,zinc alloy,cold rolled steel,aluminium |

| Coating | Top paint:10-25 micron(Normal 10-12 micron) |

| Back paint:5-12 micron(Normal 5-7 micron) | |

| ID(mm) | 508/610mm |

| Coil weight(ton) | 3-9 ton |

| Coating types | Top paint:PVDF,HDP,SMP,PE,PU |

| Functions: | Decorative,Machinability,Weather resistance,Scrath resistance,Stain resistance,Chemical resistance,Adhesion resistance |

| Primer paint: | polyurethane,Epoxy,PE |

| Back paint: | Epoxy,modified polyester |

- Q: what is the difference between METAL and STEEL?

- A metal is a chemical element that is a good conductor of both electricity and heat and forms cations and ionic bonds with non-metals. Steel is a compound made from Iron and Carbon. Ratios of 0.2% and 2.1% by weight (information by wikipedia)

- Q: I live in the Black Hills and I need to re-side my cottage. I like the look of vinyl. I've heard pros and cons about both steel and vinyl. Is steel really that easy to dent? It just doesn't look as 'clean' as vinyl. Also what 3 color combos do you like? My cottage has shutters.

- I have steel siding, and it is a pain in the butt. It's much harder to keep clean than vinyl. As for color combos, I love mine, sunny yellow with off white trim, and brick red for the doors. I added new brushed chrome doorknobs and brushed chrome rails around the porch, and it looks awesome. I am planning to have the steel siding replaced with vinyl though.

- Q: What are the dimensions of steel coils used in the storage tank industry?

- Steel coils used in the storage tank industry come in various dimensions, depending on the specific requirements of the tank being manufactured. Generally, these coils are available in different sizes and thicknesses. The width of the steel coils can range from approximately 600 millimeters to 2,400 millimeters. Similarly, the length can vary from a few meters to tens of meters. The thickness of the coils can also differ, typically ranging from 1.5 millimeters to 10 millimeters or more. Factors such as the size and capacity of the storage tank, the material being stored, and the structural requirements of the tank determine these dimensions. Consequently, the tank manufacturer or designer would determine the specific dimensions for a given storage tank project, following industry standards and project specifications.

- Q: How are steel coils used in the oil and gas industry?

- Steel coils are commonly used in the oil and gas industry for various purposes such as manufacturing pipelines, storage tanks, and offshore platforms. These coils are formed into cylindrical shapes and serve as the main structural component for these applications, providing strength, durability, and resistance to extreme conditions. Additionally, steel coils are used in the production of equipment like heat exchangers, compressors, and drilling machinery, which are essential for the extraction, processing, and transportation of oil and gas.

- Q: How long do steel coils typically last?

- Steel coils typically last for several decades, with an average lifespan ranging from 20 to 30 years. However, the actual durability and lifespan depend on various factors, such as the quality of the steel, the environment it is exposed to, how well it is maintained, and the frequency of use.

- Q: What is the average lifespan of a steel coil storage rack?

- The average lifespan of a steel coil storage rack can vary depending on various factors such as the quality of the rack, the frequency and intensity of use, and proper maintenance. However, a well-maintained and durable steel coil storage rack can typically last for several decades.

- Q: How are steel coils used in the production of industrial machinery?

- Steel coils are used in the production of industrial machinery as they provide a strong and durable material for various components. These coils are often shaped and cut to specific sizes to create parts such as gears, shafts, and frames, which are essential for the functioning of machinery. The high strength and flexibility of steel coils make them ideal for withstanding heavy loads and harsh operating conditions, ensuring the reliability and longevity of industrial machinery.

- Q: When I got my AR-15 I was told that I should get either get Brass or Steel Case ammo and stick with one or the other, I was wondering why? It surely wouldn't damage anything switching back and forth between the two would it? I got steel case ammo and I have stuck with It and probably will either way, I was just wanting to know it I ever wanted to get some Hornady's or somthing like that.

- When I first got my ar i used 500rds of wolf steel but since i heard its bad I only use brass but I did shot 30rds of steel then 30rd brass one time at the range and I have not had any problems with it. I have put 700rds though it 500 steel.

- Q: How are steel coils measured for thickness?

- Steel coils are measured for thickness using a device called a micrometer or a thickness gauge. The micrometer is pressed against the coil's surface, and the measurement is displayed on its calibrated scale, providing an accurate reading of the steel coil's thickness.

- Q: is there a type of steel that is stronger or does the rail represent the top of the line?

- No, train tracks are not made of the strongest steel. Actually, I believe they are made from a rather mild steel, maybe a high-carbon steel in the curves, but no means is this top of the line. Probably the best all around high strength steel, if you count hardness, tensile strength, shear, and yield is Eglin steel. It has a yield of about 245,000 psi an ultimate strength of around 293,000 psi a harness of 45.6 and an impact of about 75 joules. It's cheaper than exotic alloys, you can build aircraft with the stuff because weight isn't an issue and it's plenty strong enough. Its also very strong even in extreme temperatures. The material has a wide range of other applications, from missile parts and tank bodies to machine parts.

Send your message to us

ASTM A653 PPGI Prepainted Galvanized Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords