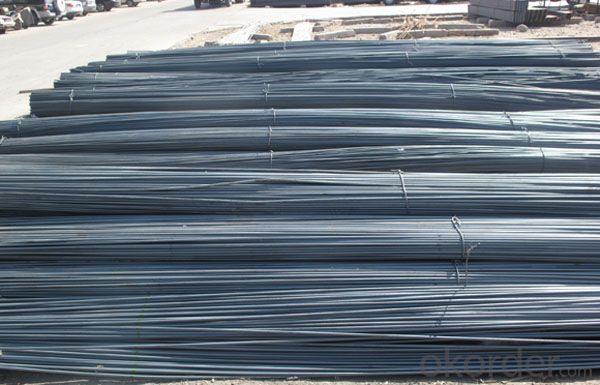

ASTM A615 deformed steel bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering ASTM A615 deformed steel bar for construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

ASTM A615 deformed steel bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's deformed steel bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specificati

Hot Rolled Steel Rebar HRB 500B

1.China direct supplier

2.Best service

3.Competitive price

4.Quantity assured

Product Description

| Name | Steel,Hot Rolled Steel Structure,Deformed Steel Bar,China Manufacture H500B 12M |

| Standard | ASTM A615 /BS BS 4449 /GB HRB/ JIS G3112 |

| Grade | HRB500B |

| Diameter | 12mm-40mm |

| Length | 6-12m |

| Technique | Low temperature hot-rolling reinforcing deformed steel rebar |

| Tolerance | As the standard or as your requirement |

| Application | Building, construction, road, bridge,etc |

| Certificated | BV |

| MOQ | 500tons per size steel rebar |

| Packing details | Steel rebar packed in bundle or as your requirement |

| Delivery | Within 30 days after deposit |

| Payment | T/T or L/C |

Chemical Composition

Grade | Technical data of the original chemical composition (%) | |||||||

C | Mn | Si | S | P | V | |||

HRB400 | ≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | ||

Physics capability | ||||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation (%)

| ||||||

≥400 | ≥570 | ≥14 | ||||||

Theorectical weight

Diameter (MM) | Cross Sectional Area (MM2) | Theorectical Weight (KG/M) | Weight of 12M Bar (KG) | A Ton Contains 12M Bars (PCS) |

| 6 | 28.27 | 0.222 | 2.664 | 375.38 |

| 8 | 50.27 | 0.395 | 4.74 | 210.97 |

| 10 | 78.54 | 0.617 | 7.404 | 135.06 |

| 12 | 113.1 | 0.888 | 10.656 | 93.84 |

| 14 | 153.9 | 1.21 | 14.52 | 68.87 |

| 16 | 201.1 | 1.58 | 18.96 | 52.74 |

| 18 | 254.5 | 2 | 24 | 41.67 |

| 20 | 314.2 | 2.47 | 29.64 | 33.74 |

| 22 | 380.1 | 2.98 | 35.76 | 27.96 |

| 25 | 490.9 | 3.85 | 46.2 | 21.65 |

| 28 | 615.8 | 4.83 | 57.96 | 17.25 |

| 32 | 804.2 | 6.31 | 75.72 | 13.21 |

| 36 | 1018 | 7.99 | 98.88 | 10.43 |

| 40 | 1257 | 9.87 | 118.44 | 8.44 |

FAQ:

Q1: Can stainless steel rust?

A1: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

- Q: What is the process of bending steel rebars?

- The process of bending steel rebars involves using specialized tools and equipment to apply force and create a desired shape or angle in the steel bars. This can be done manually or with the help of machines such as hydraulic benders. The rebars are typically heated to a specific temperature to make them more malleable, and then they are carefully bent using the appropriate bending technique. The process requires skill, precision, and knowledge of the properties of steel and the desired bending specifications.

- Q: How are steel rebars protected from fire during construction?

- Steel rebars are protected from fire during construction by applying fire-resistant coatings or by using fireproofing materials such as spray-applied fireproofing or intumescent paints. These protective measures help to delay the heating of the steel rebars and prevent them from losing their structural integrity in the event of a fire.

- Q: What's the difference between earthquake resistant thread steel and common thread steel?

- Seismic steel can meet all the performance indexes of ordinary steel, but also can satisfy the tensile strength and yield strength of the actually measured ratio of not less than 1.25 characters; yield strength and yield strength characteristics measured standard value of the ratio is not greater than 1.30; Taiyuan dedicated steel maximum force elongation of not less than 9%, the three criteria.

- Q: Can steel rebars be used in the construction of industrial facilities?

- Yes, steel rebars can be used in the construction of industrial facilities. Steel rebars are commonly used in reinforced concrete structures, providing strength and durability to support heavy loads and withstand harsh conditions. They are particularly suitable for industrial facilities that require robust and long-lasting construction materials.

- Q: What are the guidelines for protecting steel rebars during concrete placement and compaction?

- The guidelines for protecting steel rebars during concrete placement and compaction include ensuring that the rebars are clean and free from any rust, grease, or other contaminants. They should be properly tied and supported to maintain their position and prevent displacement during the concrete pouring process. Additionally, rebars should be adequately spaced to allow concrete to flow around them and provide sufficient cover, as specified in the design requirements. Care should be taken to avoid damaging the rebars during compaction, and vibrating equipment should be used cautiously to prevent excessive force or vibration that could cause rebars to shift or become dislodged. Regular inspections should be conducted to check for any damage or movement of the rebars, and necessary repairs or reinforcement should be done promptly to ensure the structural integrity of the concrete.

- Q: Can steel rebars be used in earthquake-resistant structures?

- Yes, steel rebars can be used in earthquake-resistant structures. Steel rebars provide strength and durability to reinforced concrete structures, making them capable of withstanding the forces and vibrations caused by earthquakes. The use of properly designed and placed steel rebars enhances the structural integrity and overall resistance of buildings against seismic events.

- Q: Can steel rebars be used for both residential and commercial construction?

- Yes, steel rebars can be used for both residential and commercial construction. Steel rebars are commonly used to reinforce concrete structures, such as foundations, walls, and beams, in a wide range of construction projects, including both residential and commercial buildings. The use of steel rebars provides strength and durability to the concrete, ensuring the integrity of the structure in both types of construction.

- Q: How do steel rebars affect the overall structural integrity of a building?

- Steel rebars play a crucial role in enhancing the overall structural integrity of a building. They provide reinforcement and strength to the concrete, making it more durable and resistant to various external forces. Firstly, steel rebars act as tension members in reinforced concrete structures. Concrete itself is strong in compression but weak in tension. By embedding steel rebars within the concrete, the composite material is able to withstand tensile forces without cracking or failing. This ensures that the building can withstand the tensile stresses induced by factors such as wind load, seismic activity, and ground settlement. Moreover, steel rebars help to distribute and dissipate loads evenly throughout the structure. They enhance the load-bearing capacity of the concrete, allowing it to withstand heavier loads and prevent the formation of cracks. The rebars also help to control the propagation of any cracks that may occur due to shrinkage or thermal expansion, thereby preventing catastrophic failure. In addition, steel rebars improve the ductility of the reinforced concrete structure. Ductility refers to the ability of a material to deform under stress before reaching its breaking point. By adding steel rebars, the concrete gains the ability to bend and stretch without losing its strength. This is particularly important in areas prone to earthquakes, as the building can absorb and dissipate the energy generated by seismic forces. Furthermore, steel rebars increase the durability and longevity of the building. They provide protection to the concrete by preventing corrosion and degradation. When properly coated and installed, rebars act as a barrier against moisture and other corrosive elements, thereby preserving the structural integrity of the building over time. In conclusion, steel rebars significantly impact the overall structural integrity of a building. They reinforce the concrete, enhance its load-bearing capacity, improve ductility, and increase durability. Incorporating steel rebars into construction ensures that the building can withstand various external forces and maintain its stability and safety for a prolonged period.

- Q: How are steel rebars used in flat slabs and beams?

- Steel rebars are used in flat slabs and beams to provide tensile strength and reinforce the concrete structure. They are placed within the concrete to enhance its ability to handle tensile forces, which are typically higher in flat slabs and beams. The rebars help prevent cracking and increase the overall stability and load-bearing capacity of the structure.

- Q: How do steel rebars affect the overall sustainability of bridge constructions?

- Steel rebars play a crucial role in enhancing the overall sustainability of bridge constructions. Firstly, steel rebars contribute to the longevity and durability of bridges. By reinforcing concrete structures, rebars help to distribute the tensile and compressive forces evenly, minimizing the risk of cracks and structural failure. This ensures that the bridge remains functional for a longer period, reducing the need for frequent repairs or replacements. Consequently, the use of steel rebars enhances the sustainability of bridge constructions by reducing the consumption of materials and minimizing waste generation. Moreover, steel rebars are highly recyclable, which further contributes to the sustainability of bridge constructions. At the end of a bridge's life cycle, steel rebars can be easily removed and recycled, thereby reducing the demand for virgin steel production. This not only conserves natural resources but also reduces carbon emissions associated with the manufacturing process of new steel. Additionally, the recycling of steel rebars helps to mitigate the environmental impacts of mining and extraction activities. The use of steel rebars also enables the design of lighter and more efficient bridge structures. Steel is known for its high strength-to-weight ratio, allowing for the creation of slender and aesthetically pleasing bridge designs. By reducing the weight of the bridge, less material is required for construction, resulting in lower energy consumption and carbon emissions during the manufacturing, transportation, and construction phases. Furthermore, lighter bridge structures place less load on the supporting foundation, reducing the need for extensive and costly reinforcement measures. In conclusion, steel rebars positively impact the overall sustainability of bridge constructions in multiple ways. They enhance the durability and longevity of bridges, reduce the need for frequent repairs or replacements, and minimize waste generation. The recyclability of steel rebars helps conserve natural resources, reduce carbon emissions, and mitigate the environmental impacts of mining activities. Additionally, the use of steel rebars allows for the design of lighter and more efficient bridge structures, reducing energy consumption and associated carbon emissions.

Send your message to us

ASTM A615 deformed steel bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords