Metallic Material Steel Rebar/ Deformed Steel bar /Building Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

HRB355 HRB400 HRB500 Hot Rolled Steel Rebars

Specifications

Diameter:6-50mm

Length:as your requirement

Application:construction/building

Standard:ASTM,JIS ,GB,BS.

Package: For 6-8mm, in coil. For 10-50mm, in straight-bar, usually 12m length

Table

| Name | steel rebar |

| Standard | ASTM,AISI, JIS GB,DIN,BS. |

| Grade | HRB335/400/500/400E/500E,Q235,BS/GR460B,JIS312SD390 |

| Diameter | 6,8,10,12,14,16,20,25,30,40,50mm |

| Length | 6,9,12m |

| MOQ | 25tons |

| Delivery time | within 30 days after order confirm |

| Payment | 30%TT deposit in advance the balance against the copy of B/L OR L/C at sight |

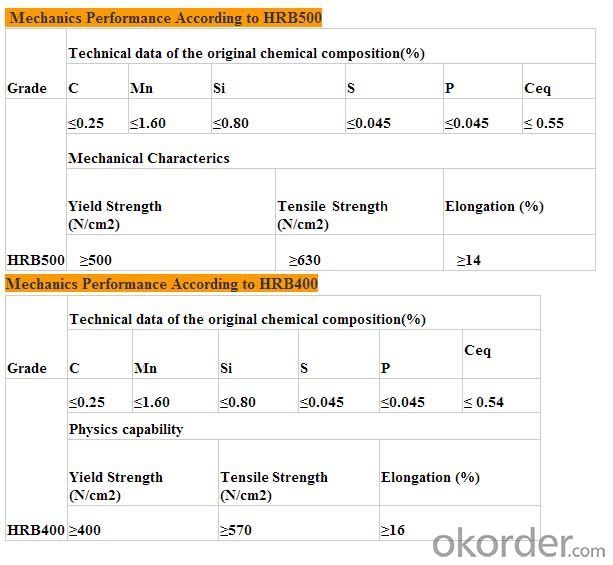

Chemical Parameters

Steel grade | C% ≤ | Si%≤ | Mn%≤ | P%≤ | S%≤ | Cr%> | Ceq≤ |

HRB335 | 0.17-0.25 | 0.40-0.80 | 1.00-1.60 | 0.045 | 0.045 | 0.3-0.4 | 0.52 |

HRB400 | 0.17-0.25 | 0.20-0.80 | 1.20-1.60 | 0.045 | 0.045 | 0.3-0.4 | 0.54 |

HRB500 | ≤0.25 | ≤0.80 | ≤1.6 | 0.045 | 0.045 | 0.3-0.4 | 0.55 |

Gr.60 | ≤0.30 | ≤0.40 | ≤1.00 | 0.050 | 0.050 | 0.3-0.4 |

Detail

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

We are a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

We provide the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: Can steel rebars be used in the construction of shopping centers?

- Yes, steel rebars can be used in the construction of shopping centers. Steel rebars are commonly used in reinforced concrete structures, including commercial buildings like shopping centers, as they provide strength, durability, and resistance to structural forces.

- Q: What are the guidelines for spacing and positioning steel rebars in concrete structures?

- The guidelines for spacing and positioning steel rebars in concrete structures are critical to ensure the structural integrity and durability of the construction. Here are some key guidelines to follow: 1. Rebar Spacing: The spacing between steel rebars in concrete structures is determined by the structural engineer or designer. It is typically expressed in terms of center-to-center spacing or clear distance between rebars. The spacing depends on the load requirements, concrete strength, and other factors specific to the project. The most common spacing ranges from 4 to 12 inches. 2. Cover Depth: The concrete cover depth refers to the distance between the outer surface of the concrete and the nearest surface of the rebar. It is essential to provide adequate cover to protect the rebars from environmental factors, such as corrosion and fire. The cover depth is typically specified in the project's design and can vary depending on the concrete's exposure conditions. 3. Rebar Positioning: The proper positioning of rebars is crucial to ensure they are placed in the designated locations within the concrete structure. The rebars should be securely supported and maintained in the correct alignment during the concrete pouring process. The positioning requirements may include specific lap lengths, overlaps, or hooking of rebars at junctions to ensure proper load transfer and structural continuity. 4. Chair Supports: Rebar chair supports are widely used to maintain the correct spacing and elevation of the rebars within the concrete structure. These supports are placed under the rebars at regular intervals to prevent sagging or displacement during concrete placement. The appropriate chair support type and height should be selected based on the project's requirements and the diameter of the rebars. 5. Tying and Binding: Proper tying and binding of rebars are essential to ensure they remain in position and maintain the required spacing during the concrete pouring process. Rebars should be tied securely using wire or rebar ties at appropriate intervals, typically every 12-18 inches. The ties should be tight enough to prevent movement but not overly tight to avoid damaging the rebars or causing concrete segregation. 6. Concrete Consolidation: During concrete placement, it is crucial to properly consolidate the concrete around the rebars to eliminate air voids and ensure adequate bonding between the concrete and the rebars. Vibrators or other consolidation techniques should be used to achieve proper compaction and ensure the rebars are thoroughly embedded in the concrete. Compliance with the guidelines for spacing and positioning steel rebars in concrete structures is essential to guarantee the structural strength, durability, and safety of the construction. It is crucial to consult and follow the project's design specifications and engage qualified professionals to ensure proper execution and adherence to these guidelines.

- Q: How do steel rebars contribute to the ductility of reinforced concrete structures?

- Steel rebars contribute to the ductility of reinforced concrete structures by providing reinforcement and increasing tensile strength. The rebars act as a skeleton within the concrete, absorbing and distributing external forces such as tension and compression. This reinforcement prevents the concrete from cracking or failing under stress, allowing the structure to withstand greater loads and deform without collapsing, thus enhancing its overall ductility.

- Q: Can steel rebars be used in both residential and commercial construction?

- Yes, steel rebars can be used in both residential and commercial construction. They are commonly used to reinforce concrete structures such as foundations, columns, beams, and slabs in both types of construction projects.

- Q: Can steel rebars be used in structures exposed to aggressive chemicals?

- No, steel rebars should not be used in structures exposed to aggressive chemicals as they are susceptible to corrosion and may weaken over time, compromising the integrity of the structure.

- Q: What are the guidelines for proper tying of steel rebars in concrete structures?

- The guidelines for proper tying of steel rebars in concrete structures include ensuring the rebars are clean, free from rust, and properly aligned according to the structural drawings. They should be securely tied at intersections using wire or mechanical connectors, with a sufficient number of ties to prevent movement during concrete placement. The ties should be tight but not excessively so, and evenly spaced along the length of the rebars. It is crucial to follow local building codes and standards, as they may provide specific requirements for rebar tying in concrete structures.

- Q: How do steel rebars perform in corrosive environments?

- Steel rebars perform well in corrosive environments, thanks to their inherent resistance to corrosion. The presence of protective oxide layers on the surface of steel rebars helps prevent the penetration of corrosive elements such as moisture and chemicals. Additionally, the use of corrosion-resistant coatings or stainless steel rebars can further enhance their performance in highly corrosive environments.

- Q: How are steel rebars bent during construction?

- Steel rebars are bent during construction using specialized tools and equipment. The process involves several steps to ensure the rebars are bent accurately and to the required specifications. First, the rebars are selected based on the design and structural requirements of the project. The rebars are typically made of carbon steel and come in various sizes and lengths. They are usually straight and need to be bent according to the specific shape and dimensions required for the construction. To bend the rebars, construction workers use a bending machine or a hydraulic bender. These machines have a set of rollers or dies that apply pressure to the rebar, bending it into the desired shape. The machine is adjusted to the required angle and radius of the bend. Before bending, the rebars are marked with measurements and reference points to ensure accuracy. The operator places the rebar into the bending machine, aligning it with the reference points. The machine is then activated, and the rollers or dies apply force to the rebar, gradually bending it to the desired shape. For complex bends or shapes, multiple bends may be required. In such cases, the rebar is bent incrementally, with the operator adjusting the machine after each bend to achieve the desired shape. It is important to note that rebars have specific bending limits to prevent them from breaking or losing their structural integrity. Construction workers must adhere to these limits and ensure that the rebars are not over-bent, as it could compromise the strength and safety of the structure. Overall, the process of bending steel rebars during construction involves using specialized equipment, careful measurements, and skilled operators to achieve the required shapes and dimensions for the project.

- Q: What are the guidelines for proper spacing and arrangement of steel rebars in concrete structures?

- The guidelines for proper spacing and arrangement of steel rebars in concrete structures are crucial for ensuring the structural integrity and strength of the final construction. Here are some key guidelines to follow: 1. Reinforcement Bar Spacing: The spacing between rebars is determined by the structural engineer and is based on the intended load and design requirements. It is generally recommended to maintain a minimum spacing of three times the diameter of the bars. This spacing helps to ensure proper concrete cover, allowing for adequate protection against corrosion and fire resistance. 2. Bar Diameter and Grade: The diameter and grade of the reinforcing bars should be selected based on the structural requirements and as specified by the engineer. Common bar diameters range from 6mm to 50mm, with higher diameters used for heavy-duty construction. The steel grade should conform to the specified standards, such as ASTM or BS, to ensure the desired tensile strength and ductility. 3. Bar Placement and Alignment: Rebars should be properly aligned and placed in accordance with the structural drawings and specifications. They should be securely supported to maintain their position during concrete placement. The bars should be placed with adequate clearance from formwork to ensure proper concrete cover, typically around 25mm to 50mm. 4. Splicing and Overlapping: When the length of the required reinforcement exceeds the available bar length, splicing or overlapping of bars is necessary. The splicing method should comply with the engineer's specifications and be performed using appropriate techniques such as welding, mechanical couplers, or lap splices. Overlapping should be done as per the specified length, ensuring sufficient overlap to maintain continuity and structural integrity. 5. Reinforcement Around Openings: Special attention should be given to reinforcement around openings like doorways, windows, and penetrations. Additional reinforcement bars, such as lintels or beams, may be required to distribute the load and prevent cracking or structural issues in these vulnerable areas. 6. Clear Cover: The clear cover is the distance between the surface of the concrete and the outer surface of the reinforcement bars. It is essential for protecting the steel from corrosion, fire, and other environmental factors. The clear cover should be maintained as specified in the design drawings, typically ranging from 25mm to 75mm depending on the structural requirements and exposure conditions. It is important to note that these guidelines may vary based on specific project requirements, local building codes, and the recommendations of the structural engineer. Therefore, it is essential to consult and adhere to the approved design documents and engage experienced professionals to ensure proper spacing and arrangement of steel rebars in concrete structures.

- Q: What is the role of steel rebars in the construction of foundations?

- Steel rebars play a crucial role in the construction of foundations by providing structural reinforcement and strength. They are embedded within the concrete to enhance its tensile strength and help distribute loads evenly, preventing cracks and structural failure. Rebars also act as a bonding agent between the concrete and the foundation, ensuring stability and durability in the overall construction.

Send your message to us

Metallic Material Steel Rebar/ Deformed Steel bar /Building Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords