Asphalt Reinforcement Geogrids for Roadbed Strengthening

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

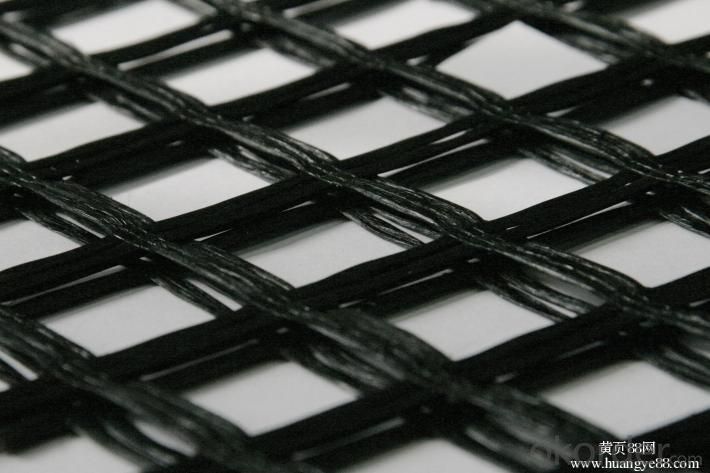

Structure of Fiberglass Geogrid

Fiberglass geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed. This product is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile strength, low unit extension, high flexibility, and favorable high and low temperature resistance. The products after surface covering own the favorable property of alkali resistance and aging resistance

Main Features of the Fiberglass Geogrid

Reinforcement fiberglss geogrid

made of fiberglass,glassfiber

fiber glass mesh

Packaging & Delivery

| Packaging Details: | PP bags or PE film. Or Packed as customers' requests. |

| Delivery Detail: | 10-20days after the contract is effective |

Fiberglass Images

Fiberglass Geogrid Specification

Property | Test Method | TGSB 30-30 | TGSB 40-40 | TGSB 50-50 | TGSB 60-60 | |

Ultimate tensile strength(1) (kN/m) | MD |

EN ISO 10139

| 30 | 40 | 50 | 60 |

CD | 30 | 40 | 50 | 60 | ||

Elongation at maximum load (%) | MD | 3 | ||||

CD | 3 | |||||

Approximate mesh size(mm) | 12.7×12.7 25.4×25.4 40×40 | |||||

Roll Width (m) | 1-6 | |||||

Roll Length(m) | 50-200 | |||||

Property | Test Method | TGSB 60-60 | TGSB 70-70 | TGSB 80-80 | TGSB 90-90 | |

Ultimate tensile strength(1) (kN/m) | MD |

EN ISO 10139

| 60 | 70 | 80 | 90 |

CD | 60 | 70 | 80 | 90 | ||

Elongation at maximum load (%) | MD | 3 | ||||

CD | 3 | |||||

Approximate mesh size(mm) | 12.7×12.7 25.4×25.4 40×40 | |||||

Roll Width (m) | 1-6 | |||||

Roll Length(m) | 50-200 | |||||

Property | Test Method | TGSB 100-100 | TGSB 120-120 | TGSB 130-130 | TGSB 150-150 | |

Ultimate tensile strength(1) (kN/m) | MD |

EN ISO 10139

| 100 | 120 | 130 | 150 |

CD | 100 | 120 | 130 | 150 | ||

Elongation at maximum load (%) | MD | 13 | ||||

CD | 13 | |||||

Approximate mesh size(mm) | 12.7×12.7 25.4×25.4 40×40 | |||||

Roll Width (m) | 1-6 | |||||

Roll Length(m) | 50-200 | |||||

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q: How about your company?

A:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q.Does your products have good qualitity?

A:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q:How long can we receive the products after purchase?

A:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: How do geogrids improve the performance of flexible pavements?

- Geogrids improve the performance of flexible pavements by enhancing their strength and stability. They provide reinforcement and prevent the spreading of cracks and ruts, increasing the pavement's resistance to traffic loads. Additionally, geogrids help to distribute the load more evenly across the pavement, reducing the potential for deformation and extending its lifespan.

- Q: Can geogrids be used in shoreline erosion control projects?

- Yes, geogrids can be used in shoreline erosion control projects. Geogrids are commonly used in these projects to stabilize the soil and prevent erosion by reinforcing the shoreline and providing structural support. They can effectively control erosion and protect the shoreline from further degradation.

- Q: Are geogrids resistant to extreme temperatures?

- Yes, geogrids are generally resistant to extreme temperatures. They are designed to withstand hot and cold weather conditions without significant degradation, making them suitable for a wide range of environmental applications.

- Q: What are the factors that affect the cost-effectiveness of geogrids?

- The factors that affect the cost-effectiveness of geogrids include the initial cost of the geogrid material itself, the installation and construction costs, the expected lifespan and durability of the geogrid, the specific application and site conditions, and the long-term cost savings or benefits achieved by using geogrids compared to alternative solutions. Other factors such as maintenance requirements, environmental considerations, and the availability of skilled labor and expertise can also influence the overall cost-effectiveness of geogrids.

- Q: Can geogrids be used in reinforcement of gabion structures?

- Yes, geogrids can be used in the reinforcement of gabion structures. Geogrids are commonly used to provide stability and enhance the strength of gabion walls by improving load distribution and reducing soil movement. They are typically installed horizontally within the gabion structure to increase its overall stability and prevent deformation.

- Q: What is the lifespan of geogrids in typical applications?

- The lifespan of geogrids in typical applications can vary depending on factors such as the type of geogrid, the quality of the material, and the specific application. However, geogrids are designed to be durable and have a lifespan ranging from 20 to 75 years in most cases.

- Q: How do geogrids improve soil reinforcement?

- Geogrids improve soil reinforcement by providing additional tensile strength to the soil, preventing lateral movement and improving its overall stability. They act as a reinforcement material that distributes the load over a wider area, reducing the stress on the soil and preventing its failure. Additionally, geogrids increase the frictional resistance between soil particles, enhancing the soil's shear strength and preventing soil erosion.

- Q: What are the limitations of using geogrids?

- Some limitations of using geogrids include their high initial cost, potential for damage during installation, limited effectiveness in certain soil conditions, and the need for proper maintenance and monitoring to ensure long-term performance. Additionally, geogrids may not be suitable for all applications and may require technical expertise for proper design and installation.

- Q: How do geogrids improve the performance of geocells?

- Geogrids improve the performance of geocells by providing additional reinforcement and stabilization. They enhance the load-bearing capacity of geocells, improve soil confinement, and prevent lateral movement and deformation. Geogrids also distribute applied loads more evenly, reducing stress on the geocell walls and increasing overall stability.

- Q: How long do geogrids typically last?

- Geogrids typically have a lifespan of 20 to 50 years, depending on factors such as installation quality, environmental conditions, and the specific application they are used for.

Send your message to us

Asphalt Reinforcement Geogrids for Roadbed Strengthening

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords