Asphalt Reinforced Fiberglass Rail Track Reinforcement Geogrids

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid with Asphalt Reinforcement

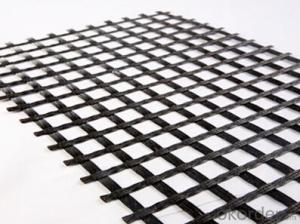

Description Of Fiberglass Geogrid with Asphalt Reinforcement:

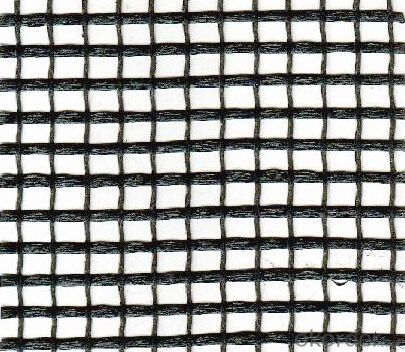

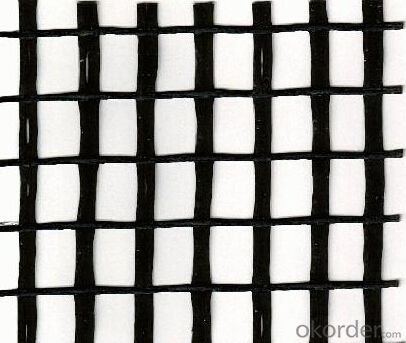

1. A kind of planar mesh material using alkali-free fiberglass yarn as base body and

then coated with high quality modified asphalt.

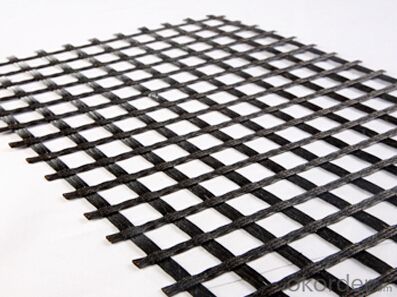

2. Warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant.

3. Coated with asphalt making full protection of the fiberglass matrix and greatly

improving its wear and shear resistance.

4. Having a good performance in pavement strengthening, track cracking and solving

difficulties of strengthening the bituminous pavement.

Main Features of Fiberglass Geogrid with Asphalt Reinforcement:

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

Specifications of Fiberglass Geogrid with Asphalt Reinforcement:

Tensile Strength (KN) | Warp | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >200 |

Weft | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >120 | |

Elongation(%) | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | |

Mesh Size(mm) | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | |

Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

Temperature Resistant(℃) | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | |

Resin Content (%) | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | |

Glue Type | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | |

Applications of Fiberglass Geogrid with Asphalt Reinforcement:

1. Maintenance of old asphalt road reinforcement of asphalt pavement.

2. Converting old cement concrete road into composite road.

3. Restraining reflection cracking caused by block shrinkage.

4. Preventing and controlling the cracking caused by new and old combination and uneven settlement.

5. Road extension.

6. Reinforcement of soft soil foundation and overall strength of roadbed.

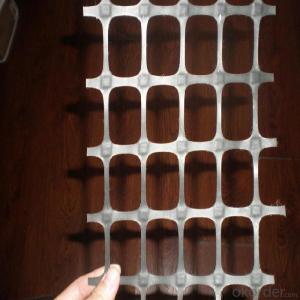

IMages of Fiberglass Geogrid with Asphalt Reinforcement:

FAQ of Fiberglass Geogrid with Asphalt Reinforcement:

1. What are we supplying?

We are specialized in producing Geosynthetic materials, like Geogrid Series, HDPE Geocell, Geonet, Geotextile, Geomat, Tri Denmensional Composite Grainage Geonet, and Geomembrane Series.

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can geogrids be used in underwater applications?

- Yes, geogrids can be used in underwater applications. They are often used to stabilize soil and prevent erosion in underwater environments such as riverbanks, shorelines, and underwater slopes. Geogrids are designed to withstand the hydraulic forces of water and provide long-term stability in these challenging conditions.

- Q: Are geogrids resistant to corrosion?

- Yes, geogrids are typically resistant to corrosion. They are made from materials such as high-density polyethylene (HDPE) or polyester, which are not prone to corroding when exposed to moisture or chemical elements. This corrosion resistance makes geogrids suitable for various applications, including soil stabilization, erosion control, and reinforcement in civil engineering projects.

- Q: How are geogrids installed in the field?

- Geogrids are typically installed in the field by first preparing the soil surface and removing any debris or vegetation. The geogrid is then rolled out and placed on top of the prepared soil. It is important to ensure that the geogrid is properly aligned and overlapping if multiple rolls are being used. The edges of the geogrid are then securely anchored using stakes or pins to prevent movement during installation. Finally, the soil is backfilled and compacted over the geogrid to provide additional support and load distribution.

- Q: Are geogrids resistant to alkali degradation?

- Yes, geogrids are generally resistant to alkali degradation. They are designed to withstand harsh environmental conditions, including exposure to alkaline substances, without significant degradation or loss of strength.

- Q: What are the durability characteristics of geogrids?

- Geogrids have excellent durability characteristics due to their high tensile strength and resistance to environmental factors such as UV radiation, chemical exposure, and temperature variations. They are designed to withstand heavy loads and prolonged use without significant deformation or degradation, offering long-term stability and performance in various soil reinforcement applications.

- Q: GDZ150 type one-way steel plastic welding geogrid D in the construction of the roadbed is horizontal paving also vertical spread?

- The direction of the pulling force is consistent with the direction of the road extension

- Q: How do geogrids help in reducing the carbon footprint of a project?

- Geogrids help in reducing the carbon footprint of a project by providing a sustainable and environmentally-friendly solution for soil stabilization and reinforcement. By using geogrids, less excavation and material are required, reducing the need for transportation and minimizing energy consumption. Additionally, geogrids can extend the lifespan of infrastructure, reducing the need for frequent repairs and replacements, which further reduces carbon emissions associated with construction.

- Q: What is the difference between plastic geogrid and grid

- It's not the same thing

- Q: Are geogrids suitable for reinforcement of mechanically stabilized earth retaining walls?

- Yes, geogrids are suitable for reinforcement of mechanically stabilized earth retaining walls. Geogrids provide additional tensile strength and stability to the soil, increasing its overall load-bearing capacity. They help prevent soil movement, erosion, and potential wall failure, making them a reliable and commonly used reinforcement solution for retaining walls.

- Q: Glass fiber grille modified asphalt, polyester grille coated PVC.

- This is the business secret of the production enterprise.

Send your message to us

Asphalt Reinforced Fiberglass Rail Track Reinforcement Geogrids

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords