Armstrong Fiberglass Ceiling Panels - Acoustic Fiberglass Ceiling Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass ceiling board acoustic ceiling

Specifications:

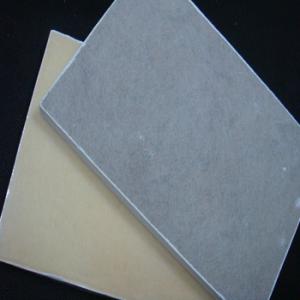

Main Material: Fiberglass wool

Density: Standard 100kgs/m3

Thickness: 15mm,20mm, 25mm and etc.

Size: 600*600mm,600*1200mm and etc.

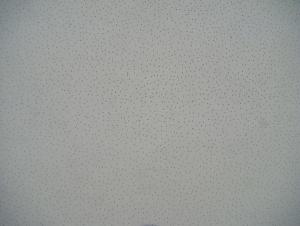

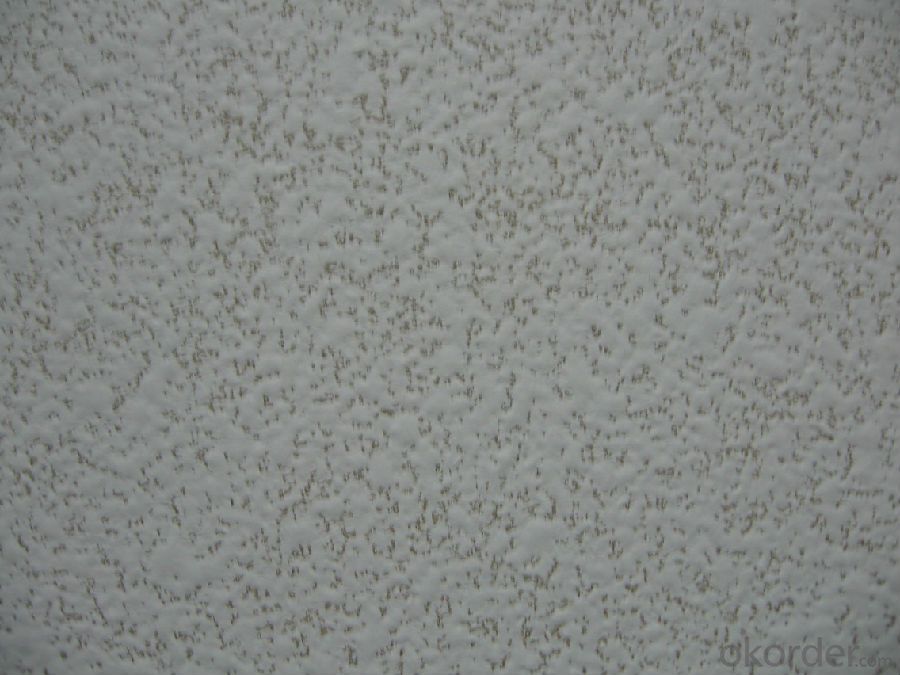

Textures: White painted, Mix Acoustic, White Spray, BlackSpray

Edge: Square, Tegular for 15/24 grids, Concealed

Black spray White spray

Mix Acoustic White painted

Fiberglass ceiling board acoustic ceiling

Quick Detail:

Non-combustible;

No sagging, warpping or delaminating;

Green building material;

Excellent sound absorption;

With different pattern available;

Applications:

Halls, Classrooms, Offices, Shopping centers, etc.

Competitive Advantages:

Fire-resistant;

Thermal-insulation;

Humidity-resistant;

Cleanability;

Environmental;

Elegant;

Safety and Convenience;

Fiberglass ceiling board acoustic ceiling

- Q: What is soft film ceilings?

- Soft film smallpox - founded in Switzerland in the nineteenth century, and then by the French Farmland SCHERRER (Flanders. Scholes) in 1967 to continue to study and successfully promote the European and American countries to the smallpox market, soft film ceiling Has become the preferred material for ceiling materials. The soft film is made of special polychlorohexene material, 0.18 mm thick, about 180 to 320 grams per square meter, and its fire rating is B1 grade. The soft film is formed by one or more cuts and is finished with high frequency welding. The soft film needs to be measured in the field after the size of the ceiling, produced in the factory. Soft film size stability at -15 degrees Celsius to 45 degrees Celsius. Transparent film ceiling can be used with a variety of lighting systems (such as neon lights, fluorescent) to create a fantastic, shadowless indoor lighting effects. At the same time to abandon the glass or plexiglass bulky, dangerous and small assembly of the shortcomings, has gradually become a new decorative highlights.

- Q: Is anyone familiar enough with asbestos to know if this ceiling tile contains them:It is clearly damaged and need to be removed if it does. Thanks.

- No its a fiberglass tile with a decorative covering. Fiberglass is still an irritant though so wear gloves and a mask.

- Q: How to enhance the sound insulation of the room?

- The room is to take a strict sound insulation measures on the walls, floors and ceilings. The final result is the construction of a room inside the room. All the studios use this structure. Of the sound insulation characteristics of more than -50dB. Even with the ideal sound insulation features up to -60dB ~ 65dB recording studio comparable to the inside and outside the wall completely isolated, do not send any sound vibration, "room" structure is necessary The use of isolation devices, the construction of more complex. This level of noise walls, do not allow such as power supply, audio equipment, telephone, air conditioning and other sockets have installation gap.Therefore, the actual plan, should consult the corresponding qualification of large decoration company. "Room room" manufacturing costs will be much higher than any of the previous transformation method, up to more than 10,000 yuan per square meter.Obviously this is not the general working class can expect the sound insulation to pay attention to the level of their own home theater To achieve what kind of standards, the mind to have a number, so the system should take appropriate measures to spend the least money with their own economic capacity, appreciation of the level of sound insulation is the most important.

- Q: I'm afraid that joint compound might not adhere well to plywood.

- Joint compound will adhere very well to the plywood, but the movement of the plywood from temperature and humidity changes will cause the compound to crack. If this is an issue, batten strips may be the answer.

- Q: Epoxy resin when the ratio of curing agent than the high proportion of what impact? What is the impact of low. What is the reason for hardening after curing?

- Curing agent will increase the speed of curing more, put less curing time will be slower. But do not be higher or lower too much, whether it is more or less, excessive will appear false curing. That is what you said after curing is not hard

- Q: How to choose how to buy closet door ah?

- When choosing a wardrobe, note the following: 1. Is the thickness of the door panel full of thick, high enough height. Sliding door with the wood, the best choice 10mm or 12mm thick plate, use up strong, stable, durable; slightly worse will use 8mm thick, it is relatively thin, frivolous. Door height is decided whether the decoration to the ceiling, requiring a single plate height of 2.8 meters or more, up to the ceiling. 2. Whether the variety of doors and materials are rich and varied. Different consumer ideas correspond to different color hobbies. Currently on the market for the production of sliding doors of the main materials are wood, glass, mirrors and other special materials. Colors are beech, cherry, maple, maple, oak, black walnut, white pine and so on. 3. Whether the door and the border are consistent. Brand wardrobe cabinet door frame, door from the same manufacturers, the color lines can be achieved consistent, supporting unity. And miscellaneous wardrobe is often patchwork, can only find similar color plate, border, can not be completely consistent. 4. Whether the wheels are smooth, pressure, wear, safe and reliable. Brand wardrobe pulley is generally made of carbon glass fiber (international new high-tech materials) made with within the ball, with a non-drying lubricant, it can easily push and pull, smooth and flexible, and bearing capacity, pressure, wear Not deformed. Pulley guide is the sliding door of the core technical parts, we must carefully choose. 5. Whether the cabinet is professional, whether the design is scientific fashion. Currently popular fashion wardrobe cabinet, the design is very scientific and reasonable

- Q: I just bought a home with an unfinished basement. I was thinking of finishing the basement and creating a game room. I wanted to soundproof it but I dont want to spend a ton of money. I know that I can buy soundproof drywall but that stuff is expensive!Is there anything that I can stuff between the ceiling beams to soundproof the room? I dont want to put in a double layer of sheetrock becuase the ceiling is already only 7 feet.Thanks!

- Some people use egg cartons.

- Q: We have removed our rough sawn cedar from our cathedral ceiling in our 80's home. We found fiberglass insulation and 2x6 joists (the roof is directly above). The first electrician came out before we removed the ceiling and assumed there was no insulation and said we needed to get spray insulation because of the condensation can lights can cause. The other electrician we called out came after we removed the ceiling and did not say anything about condensation. Neither said anything about ice dams. I am seeing all this pretty scary stuff when doing my research, and am thinking we shouldn't put in recessed lighting now! We live in Wyoming where the climate can be pretty cold, but is usually very dry.So, if we use LED lamps and IC airtight housings, will the heat transfer really be bad enough to cause condensation and/or ice dams? Would it help to put some foam board between the shallow housings and the roofing substrate (if it fits)? We are only planning on putting up 6 6" lights in a 10x20 room...

- I highly recommend you beef up the structure of your ceiling rafters and that will solve multiple issues I see in this project. That will give you plenty of clearance for lighting fixtures and it will also allow for more insulation along with proper ventilation. If it were my ceiling I would sister a minimum of 2 x 10 lumber to the sides of the existing 2 x 6 rafters you now have. Those 2 x 6 rafters are way under size for heavy snow loads and the current space in no way allows for enough insulation. I have done this exact kind of thing in my home when I used excess attic space to build a large multipurpose room. I nailed and used construction adhesive to attach or sister beefy 2 x 10's to the sides of each of my existing roof rafters. Then I could properly insulate the ceiling of the new room along with making the structure much stronger. The extra thickness of the space won't be noticeable at all when the ceiling is put back in but you'll have a much safer and sturdier roof and ceiling. If you're doing this project with a building permit then what I've described above will be required by the building inspector for sure. You will have to meet the building code for the R value of the insulation etc etc. But, even if you're doing this without involving the building dept, it will be in your best interest to beef up the lumber and add the additional insulation anyway. It will be a very small additional cost to pay considering the savings you'll recoup in energy bill not to mention the overall safety factor. Do a search on sistering roof rafters and you can find a good bit of info online if what I've said doesn't make sense to you. If I can give you additional advice or help you find more info online please get in touch. Good luck and I hope this helps!

- Q: What type of contractor would be able to remove the insulation from the crawlspace ceiling and put it against the outside wall where it would actually be useful?

- There is normally some insulation in the ceiling of the crawl space. Heat moves from HOT to Cold, and the cool crawl space should be insulated from your kitchen. If your Kitchen floor is cold you may even want more. Or put carpet in you kitchen. (It is done.) Insulation is normally thickest (6 to 12 inches) above living space ceilings, next thickest (3 to 6 inches) in living space walls, and thinnest below floors (3 inches). Any home builder, home addition contractor, or serious handyman can add more insulation to your crawl space.

Send your message to us

Armstrong Fiberglass Ceiling Panels - Acoustic Fiberglass Ceiling Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords