White Packaging Tape Paper - Anti-Slip Floor Tape Colorful Color for Promotion

- Loading Port:

- Nantong

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1500 roll

- Supply Capability:

- 5550000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

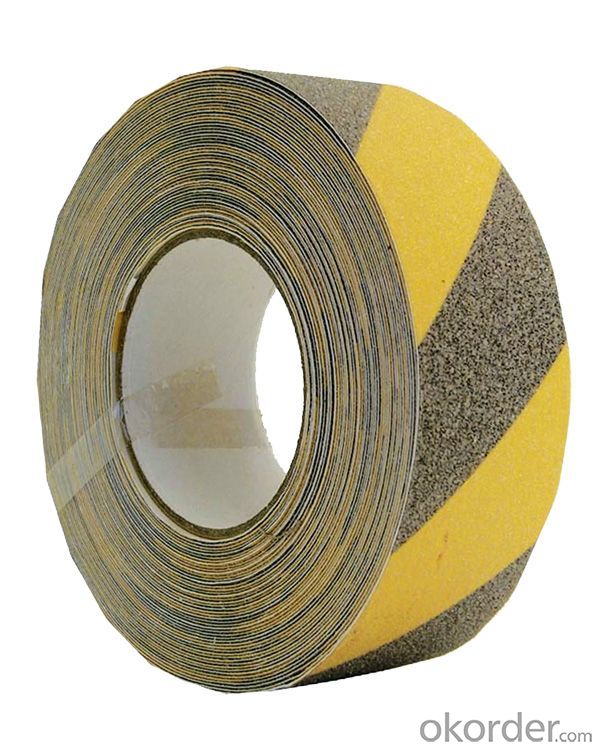

Anti-Slip Floor Tape Colorful Color for Promotion

1. Description of Anti-Slip Tape

Structure:

1) Surface: choice anti-slip sand, rubber anti-slip fiber, sand-free special anti-slip material

2) Middle layer: PET,PP,PVC and aluminum etc

3) Base Glue: ready-to-use waterproof strong viscose

4) Base paper: white/leather silicone paper

Appearanceof colors:

Black,grey,red,orange,blue,yellow and black,red and white,transparent,white,reflective,night light-emitting etc. Printing a variety of beautiful picture and patterns according to customer requirements.

2. Advantages of Anti-Slip Tape

1 ) Different temperature resistance with good adhesion.

2 ) High tensile strength, good resistance of damage,no residue, eco-friendly.

3 ) Printing logo on paper core and carton mark as customers' need

4 ) SGS, ISO,BV, CTI certificates approved

5)Professional teamwork for orders

6)No.365 on the 2012 Fortune Global 500

7) Professional manufacturer with 31 years experiences of adhesive tapes

Special size,color can be made according to customer's requirement

3. Application of Anti-Slip Tape

1) Used for normal masking, such as indoor painting, car painting, car decoration painting.

2) Used in electronic industry and electric appliances for fixing and protection purposes.

3) Mainly designed for ordinary wrapping ,craftwork, lightduty masking.

4) Furniture, appliance automobile /shoes spray painting, color making, decoration and labels.

4. Details of Anti-Slip Tape

Material | Surface;Middle layer;Base Glue;Base paper |

Used | Widely used in the floor,ground |

Printing | Offer printing |

Color | Red, milky, green, white , yellowish, blue, black, or at will. |

Packaging | 6rolls/shrink,12rolls/shrink,72rolls/ctn,144rolls/ctn. |

MOQ | 20ft container or as you need. |

Payment terms | 30% in advance,70% balance the copy of B/L. |

Delivery time | 15workdays except the affirming date of logo on paper core and carton after receiving the deposit. |

Jumbo rolls size

| 1260mm*1800m, 1260mm*1000m |

Width | 3mm~1260mm normal width:12mm,18mm,24mm,36mm

|

Length | 10m~1800m normal length: 20m,33m,50m,100m |

Port | Shenzhen |

Certifications | ISO.9001.2008. and SGS. |

Certification:

- Q: Is packaging tape safe to use on plastic picture frames?

- Yes, packaging tape is generally safe to use on plastic picture frames. It provides a secure and temporary hold without causing damage to the frame's surface. However, it is important to remove the tape carefully to avoid peeling off any paint or finish.

- Q: How does packaging tape perform when exposed to sunlight?

- Extended exposure to sunlight can negatively affect the performance of packaging tape. Ultraviolet rays present in sunlight can cause the tape to deteriorate and lose its adhesive properties. This can result in the tape becoming brittle, yellow, and prone to peeling off. Additionally, the heat from sunlight can cause the tape to melt or deform, further impacting its effectiveness. To avoid any potential damage caused by sunlight, it is advised to store packages with packaging tape in a cool and dark location, ensuring the tape maintains its effectiveness.

- Q: Is packaging tape resistant to extreme temperatures or weather conditions?

- Packaging tape is typically constructed to endure extreme temperatures and diverse weather conditions, although the degree of resistance may fluctuate depending on the tape's specific type and quality. Most packaging tapes are composed of robust materials like polypropylene or PVC, renowned for their durability and ability to withstand environmental elements. These tapes are often treated with specialized adhesives that retain their stickiness even in harsh temperatures or humid surroundings. Concerning extreme temperatures, packaging tapes are generally engineered to withstand a broad spectrum, including both frigid and scorching extremes. They can typically endure temperatures as low as -20 degrees Celsius or as high as 60 degrees Celsius without compromising their adhesive properties or becoming brittle. Similarly, packaging tapes are designed to exhibit resistance against diverse weather conditions. They are formulated to repel moisture, humidity, and UV radiation, which are prevalent factors that can deteriorate tape quality. This resistance ensures that the tape remains intact and efficient, even when exposed to rain, snow, or direct sunlight. It is crucial to note that although packaging tape is generally resistant to extreme temperatures and weather conditions, prolonged exposure to such circumstances can still impact its durability. Therefore, it is advisable to store and utilize packaging tape in a controlled environment whenever feasible to guarantee maximum effectiveness.

- Q: Can packaging tape be used for sealing wooden crates or pallets?

- Yes, packaging tape can definitely be used for sealing wooden crates or pallets. Packaging tape is designed to provide a strong and secure bond, making it suitable for sealing various types of materials, including wood. Its adhesive properties allow it to adhere well to both the surface of the wooden crates or pallets and the packaging materials used to enclose them, providing a reliable seal. Additionally, packaging tape is typically durable and resistant to moisture, ensuring that the contents of the wooden crates or pallets are protected during transportation or storage.

- Q: Can packaging tape be used for sealing plastic storage bins?

- Indeed, plastic storage bins can be effectively sealed using packaging tape. The tape is specifically engineered to possess robust adhesion, making it an ideal choice for securing and sealing a wide range of materials, including plastic bins. Its dependable and long-lasting seal guarantees the security and protection of the bin's contents. Nevertheless, it is crucial to carefully and firmly apply the tape in order to achieve a tight seal. Moreover, it is advisable to utilize a high-quality packaging tape that is specifically tailored for the intended purpose to obtain the best sealing outcomes.

- Q: I want to be involved in the tape industry, is the parent type their split, but do not know the parent roll cut in segmentation machine is good, or even after the parent roll processing, and also is the problem of the equipment, how much money, thank you

- Buy mother volume back, after four machines processed into finished products can be, the equipment price is: 40 thousand, -4.3 million.

- Q: What are the benefits of using silent packaging tape?

- Silent packaging tape offers several benefits including noise reduction during packaging, increased productivity due to minimized distractions, improved customer satisfaction by avoiding noisy packaging, and a more pleasant work environment for employees.

- Q: Can packaging tape be used for sealing construction materials or tools?

- Indeed, construction materials or tools can be sealed using packaging tape. The primary purpose of packaging tape is to securely seal boxes and packages, which also makes it effective for sealing construction materials or tools. Its strong and durable bond makes it suitable for sealing a wide range of materials, including wood, metal, plastic, or concrete. Nevertheless, it is crucial to take into account the weight and characteristics of the materials being sealed. In instances where heavier or more challenging construction applications are involved, specialized tapes or adhesives specifically intended for construction purposes might be more suitable.

- Q: Are there any specialty packaging tapes for specific applications?

- Yes, there are specialty packaging tapes available for specific applications. These tapes are designed to meet specific needs such as high strength, temperature resistance, moisture resistance, or delicate item protection. Examples include double-sided tapes, reinforced tapes, freezer tapes, and tamper-evident tapes. These specialty tapes offer enhanced performance and durability for specific packaging requirements.

- Q: How does packaging tape perform on porous surfaces?

- When it comes to porous surfaces, packaging tape shows decent performance, even though its adhesive strength might be slightly compromised compared to non-porous surfaces. This tape is specifically designed to stick to a variety of surfaces such as cardboard, paper, and fabric, all of which are commonly known as porous materials. However, because these surfaces are porous, some of the adhesive may seep into the material, resulting in a reduction in bond strength. Moreover, the tape may not stick as firmly to porous surfaces, which makes it more likely to peel or lift. To ensure maximum adhesion, it is recommended to make sure the surface is clean and dry before applying the tape.

Send your message to us

White Packaging Tape Paper - Anti-Slip Floor Tape Colorful Color for Promotion

- Loading Port:

- Nantong

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1500 roll

- Supply Capability:

- 5550000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords