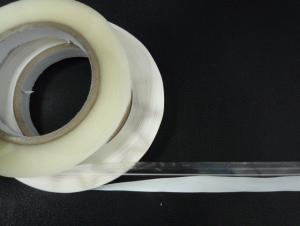

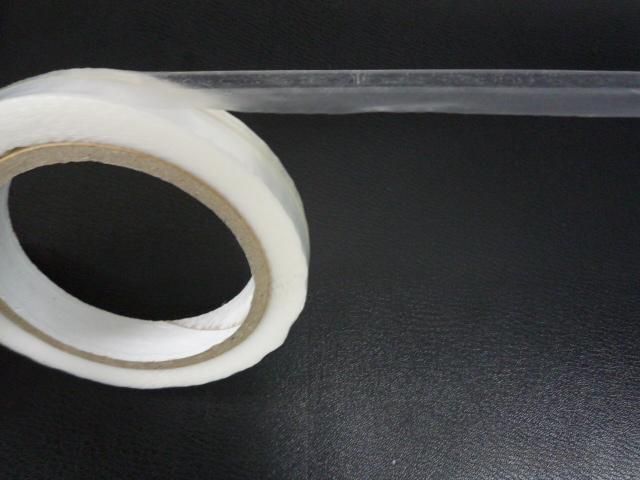

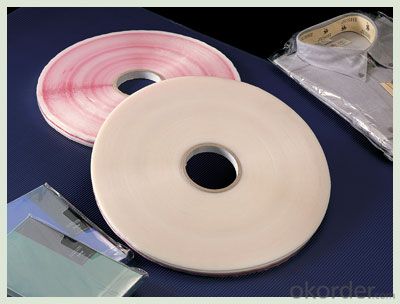

Brown Paper Packaging Tape for Resealable Bag Sealing with Big Sizes

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- USD3000 roll

- Supply Capability:

- 30 Days For 1 x 20FCL roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Resealable Bag Sealing Tape with big sizes

Suitable for sealing plastic bags such as OPP or PP .PE materials.

Reusable, no peel off of adhesive, no residue.

It does not react chemically with the contents of the bags to color changes etc.

Name Bag Sealing Tape

Technical Data of Resealable Bag Sealing Tape with big sizes

Item No BG-15P

Carrier PET film

Release Liner PE Film

Adhesive Acrylic Adhesive

Release Liner width 13/14mm

Carrier Width 6mm

AB Side Coating Width 4mm/7mm (middle glue)

Remarks of Resealable Bag Sealing Tape with big sizes

The data above are typical results and subject to change without notice.

Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

The products should be stored at room temperature and be kept away wet and/or heat source.

It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

The users should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for their special purpose and technique.

- Q: Can packaging tape be used for sealing packages with high-value contents?

- Indeed, packaging tape proves useful in sealing packages that contain valuable items. Designed with the specific purpose of ensuring the secure closure of packages, it offers protection against tampering, moisture, and transit-related harm. Possessing strength and durability, packaging tape usually boasts a resilient adhesive backing that guarantees a lasting seal. By employing packaging tape correctly, one can effectively safeguard packages that hold valuable contents, thereby guaranteeing their safe arrival. However, it is crucial to bear in mind supplementary security precautions, such as utilizing tamper-evident tape or incorporating additional layers of protection, depending on the worth and fragility of the items contained within.

- Q: Is packaging tape easy to write on?

- Yes, packaging tape is generally easy to write on. It provides a smooth surface for writing and most pens or markers adhere well to it, allowing you to write clearly and legibly on the tape.

- Q: Can packaging tape be used for sealing packages with liquid-filled containers?

- It is not advisable to use packaging tape for sealing packages containing liquid-filled containers. Although packaging tape is intended for securing boxes and packages, it lacks specific design for handling liquids. There is a higher likelihood of leakage or spillage during transit, particularly if the containers are not adequately sealed. To ensure the safe transportation of liquid-filled containers, it is recommended to employ specialized sealing methods, including shrink wrap, heat sealing, or pressure-sensitive adhesive tape specifically designed for liquid containers. These methods guarantee a more secure and leak-proof seal, thereby reducing the risk of damage or leakage while in shipping.

- Q: Can packaging tape be used for sealing packages with delicate fabrics or clothing?

- Yes, packaging tape can be used for sealing packages with delicate fabrics or clothing. However, extra care should be taken to prevent any damage to the fabric. It is recommended to use a gentle touch while sealing the package and consider adding an additional layer of protective material, such as tissue paper or bubble wrap, to provide cushioning and prevent any potential damage.

- Q: Does packaging tape come in different odor-free options?

- Yes, packaging tape does come in different odor-free options. Many manufacturers offer packaging tape that is specifically designed to be odor-free, making it suitable for use in sensitive environments or for individuals who may have allergies or sensitivities to certain scents. These odor-free options are typically made from materials that do not emit any strong smells or fragrances, ensuring a neutral and pleasant packaging experience. When purchasing packaging tape, it is always a good idea to check the product description or labeling to see if it is specifically mentioned as odor-free.

- Q: Is packaging tape safe to use on plastic hangers?

- Yes, packaging tape is generally safe to use on plastic hangers. It adheres well to most surfaces, including plastic, and provides a secure hold. However, it is recommended to use a moderate amount of tape to avoid damaging or leaving residue on the hangers.

- Q: Is packaging tape resistant to chemicals or solvents?

- Generally, chemicals and solvents do not pose a threat to packaging tape. Packaging tapes are typically composed of materials like polypropylene or polyvinyl chloride (PVC), which possess excellent chemical resistance. These materials are specifically engineered to endure exposure to a broad array of chemicals and solvents commonly found in industrial or commercial settings. Nevertheless, it is crucial to acknowledge that the resistance of packaging tape may differ depending on factors such as the brand, type, and quality of the tape. Consequently, it is advisable to review the product specifications or seek guidance from the manufacturer to obtain detailed information regarding the chemical resistance of a particular tape.

- Q: Is packaging tape easy to remove without damaging surfaces?

- Packaging tape is typically designed to be easily removed without causing any harm to surfaces. However, the ease of removal can vary depending on several factors, including the type and quality of the tape, the surface it is applied to, and how long it has been in place. Most packaging tapes are created to stick firmly to surfaces during transportation or storage, ensuring that the package remains sealed and secure. Nevertheless, they are also formulated to be peeled off easily when necessary, without leaving any residue or causing damage. In most situations, packaging tape can be removed by simply peeling it off slowly and evenly. The adhesive used in packaging tapes is generally developed to strike a good balance between sticking power and ease of removal. This allows for effortless removal without the need for excessive force or any sticky residue. However, there may be instances where the tape might be more challenging to remove, particularly if it has been in place for a long time or exposed to extreme temperatures. In such cases, using heat, such as a hairdryer, to soften the adhesive can be helpful, making it easier to peel off. It is important to note that the ease of tape removal can also be influenced by the surface it is applied to. Smooth and non-porous surfaces like glass or metal are generally easier to clean without causing any damage. On the other hand, porous or delicate surfaces like wood or painted walls may require more caution and care during removal to prevent any potential damage. In conclusion, while packaging tape is generally designed to be easily removed without causing damage, it is essential to consider factors such as tape quality, surface type, and removal technique to ensure a smooth and damage-free removal process.

- Q: Is packaging tape waterproof?

- Yes, packaging tape is typically waterproof. It is designed to be resistant to moisture and can provide a strong seal, preventing water from seeping into the package. However, it is important to note that the level of waterproofing may vary depending on the quality and type of packaging tape used. Some tapes may provide a more secure seal than others, so it is always recommended to choose a tape specifically designed for packaging and sealing purposes.

- Q: How does packaging tape perform on low-friction surfaces?

- Packaging tape generally does not perform well on low-friction surfaces. Its adhesive may struggle to stick firmly, leading to reduced adhesion and the tape easily peeling off. In such cases, it is recommended to use alternative adhesive solutions or methods specifically designed for low-friction surfaces to ensure proper packaging and sealing.

1. Manufacturer Overview

| Location | Zhengzhou, China |

| Year Established | 2009 |

| Annual Output Value | Above US$ 2 Million |

| Main Markets | 20.00% Southeast Asia 20.00% South America 10.00% Eastern Europe 10.00% North America 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin Port |

| Export Percentage | 19% - 22% |

| No.of Employees in Trade Department | 20-50 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | High; Average |

Send your message to us

Brown Paper Packaging Tape for Resealable Bag Sealing with Big Sizes

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- USD3000 roll

- Supply Capability:

- 30 Days For 1 x 20FCL roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords