Lowes Packaging Tape - Double Sided Tissue Tape Water Based Acrylic 80 Micron Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

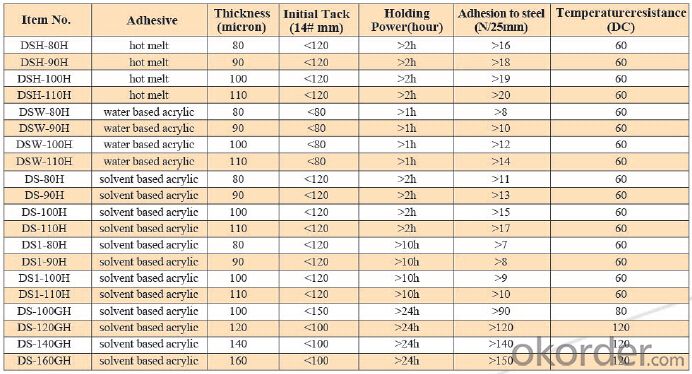

Typical Physical Reports of Double Sided Tissue Tape

Description

The Double Sided Tissue Tape is of tissue as the carrier, coating with hot melt adhesive, water based acrylic, solvent based acrylic. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

The thickness of the tape can be customized.

Application

General purpose of Double Sided Tissue Tape: widely used for bonding, fixing for leather, foam, sponge, garment, shoe, luggage, plastic, paper splicing and stationery.

Packaging & Delivery

Packaging Detail:

Log Roll: Length 1000mm; width: 1050mm, 1260mm, 1040mm..

Cut Roll: As per customer’s requirements

Delivery Detail: within 7-15 working days after receiving your deposit

Service

Sample of Double Sided Tissue Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service

Well-trained & experienced sales representative are ready to answer you.

About us

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Welcome to contact us and visit the factory!

- Q: Can packaging tape be used for sealing arts and crafts materials?

- Yes, packaging tape can be used for sealing arts and crafts materials. It provides a strong and secure bond, making it suitable for various types of materials such as paper, cardboard, and plastic. However, it is important to consider the aesthetics and longevity of the tape, as there may be more specialized options available for specific art and craft projects.

- Q: How do I remove packaging tape without damaging the surface?

- To remove packaging tape without damaging the surface, you can follow these steps: 1. Start by lightly heating the tape using a hairdryer on a low setting. The heat will soften the adhesive, making it easier to remove. 2. Gently lift one corner of the tape using your fingernail or a plastic scraper. Be careful not to use sharp objects that could scratch the surface. 3. Slowly peel the tape back at a 180-degree angle, applying steady and even pressure. If the tape resists, stop and apply more heat to soften the adhesive further. 4. If there is any residue left behind, you can use rubbing alcohol or a mild adhesive remover. Apply a small amount to a soft cloth and gently rub the residue until it lifts off. 5. Once the tape and residue are removed, clean the surface with a mild soap and water solution to remove any remaining adhesive or residue. Remember to always test any cleaning solution on a small, inconspicuous area first to ensure it doesn't damage the surface.

- Q: How do I prevent packaging tape from curling up?

- Here are some suggestions for preventing packaging tape from curling: 1. Opt for a tape dispenser: Employing a tape dispenser not only maintains the tape's straightness but also prevents it from curling. Moreover, it facilitates cutting the tape to the desired length. 2. Apply the tape evenly: While applying the tape, ensure to pull it tightly and evenly across the surface. Avoid any creases or air bubbles as they can cause the tape to curl. 3. Ensure surface cleanliness: Prior to applying the tape, guarantee that the surface is clean, devoid of dust, dirt, or moisture. These elements can interfere with the tape's adhesive properties and lead to curling. 4. Store the tape correctly: Proper storage of packaging tape is crucial for preventing curling. Keep it in a cool, dry place, away from direct sunlight. Drastic temperature fluctuations can impact the adhesive properties of the tape and result in curling. 5. Select high-quality tape: Invest in top-notch packaging tape specifically designed for long-term adhesion. Cheaper tapes often possess lower quality adhesives that are more prone to curling. 6. Utilize a heat source: If you encounter curling issues with the tape, you can attempt using a heat source, such as a hairdryer on a low setting. Gently warm the tape while applying it to activate the adhesive and minimize curling. By adhering to these suggestions, you can successfully prevent packaging tape from curling and achieve a secure and professional packaging appearance.

- Q: What are the considerations for using packaging tape on fragile items like ceramics?

- When using packaging tape on fragile items like ceramics, there are several important considerations to keep in mind. Firstly, it is crucial to select the appropriate type of packaging tape. Look for tape that is specifically designed for fragile items or delicate surfaces, as it will typically have features such as gentle adhesive and high tensile strength. This type of tape is less likely to damage or leave residue on the ceramics. Secondly, it is important to handle the ceramics with care when applying the tape. Avoid applying excessive pressure or force that could potentially cause them to crack or break. Additionally, make sure to clean the surface of the ceramics before applying the tape to ensure proper adhesion. Another consideration is the amount of tape that should be used. While it is important to secure the ceramics adequately, using too much tape can add unnecessary weight and potentially damage the fragile item. It is advisable to use just enough tape to hold the ceramics securely in place without putting excessive strain on them. Furthermore, it is recommended to use additional protective materials in conjunction with the packaging tape. Bubble wrap, foam sheets, or packing peanuts can provide extra cushioning and protect the ceramics from any potential impact or vibrations during transit. Lastly, it is crucial to label the package as fragile to ensure that handlers are aware of the delicate contents. This can help to minimize the risk of mishandling and provide an extra layer of caution during transportation. In conclusion, when using packaging tape on fragile items like ceramics, it is important to choose the appropriate type of tape, handle the ceramics with care, use the right amount of tape, employ additional protective materials, and clearly label the package as fragile. By considering these factors, you can help to ensure the safe transportation of your fragile ceramics.

- Q: Does packaging tape have a specific shelf life?

- Yes, packaging tape does have a specific shelf life. The shelf life of packaging tape typically depends on the type and quality of the tape. However, most packaging tapes have a shelf life of around 1 to 2 years if stored properly in a cool, dry place. It is always recommended to check the manufacturer's guidelines for specific information on the shelf life of a particular packaging tape.

- Q: Can packaging tape be used for sealing poly mailers?

- Indeed, poly mailers can be sealed using packaging tape. Typically, packaging tape is employed to secure diverse packaging materials, including poly mailers. This tape offers a robust and reliable seal, safeguarding the contents from spilling out or experiencing interference while in transit. Nevertheless, it is crucial to apply the tape correctly and firmly to maintain the seal's integrity. Moreover, it is advisable to opt for a top-notch packaging tape specifically designed for secure sealing to achieve optimal outcomes.

- Q: How do you store unused rolls of packaging tape?

- In order to preserve the adhesive properties of unused rolls of packaging tape, it is crucial to store them in a cool and dry location. One possible option is to utilize a plastic storage bin or container equipped with a lid, as this will shield the tape from both moisture and dust. Another alternative is to employ a dedicated tape dispenser or a tape gun with a built-in storage compartment for extra rolls. This not only keeps the tape well-organized, but also prevents it from unraveling and becoming entangled. Remember to keep the rolls in an upright position to prevent any potential damage or deformation. By correctly storing unused rolls of packaging tape, you can guarantee that they will remain in optimal condition and readily available for use when necessary.

- Q: Is packaging tape easy to tear?

- Indeed, packaging tape is typically quite simple to tear. Numerous packaging tapes are specifically crafted to be torn effortlessly by hand, eliminating the need for scissors or any other tools. Typically, the tape incorporates perforated lines or a slightly thinner portion that enables straightforward tearing. This feature renders it convenient for swiftly sealing or opening packages without encountering any inconvenience. Nonetheless, the ease of tearing may differ based on the particular brand and caliber of the packaging tape.

- Q: How wide is standard packaging tape?

- Standard packaging tape is typically 2 inches wide.

- Q: Flexo printing tape, what are the common, what are the advantages and disadvantages?

- (3) when pasting the plate, the area of the adhesive tape should be larger than the area of the printing plate. That is to say, the edge of the adhesive tape should be larger than the edge of the printing plate. EPSON will greatly reduce the risk of the warped version.(4) when printing, the interface of the printing plate should avoid the interface of the adhesive tape. If the interface of the printing plate is facing the interface of the adhesive tape, it will lead to the sticking of the printing plate at the interface.(5) in a printing plate cylinder or sleeve surface mount tape, recommend the use of scraper instead of the hand rolled plate mounting tape printability, because it is relative to the hand operation, the scraper can put more pressure on the mounting tape so that mounting tape better stick to the printing plate or the sleeve surface, while effectively avoiding bubbles; in mounting tape stuck to the surface of the plate, with a soft rubber roller instead of rolling plate flexo, in order to better fit the drive plate, bubbles, protection plate surface fine mesh point.

Send your message to us

Lowes Packaging Tape - Double Sided Tissue Tape Water Based Acrylic 80 Micron Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords