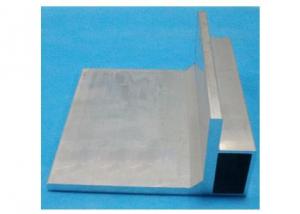

10mm Anodized Bronze Color Aluminum Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Industrial aluminium profile

1)Material : 6063 6061 6060 and different aluminium alloy

2)Status:T4 T5 T6 or other special status

3)Surface treatment: mill finish, anodized sliver ,anodized bronze, anodized champagne, anodized black pearl, various power coating color, electrostatic sliver, electrostatic champagne, electrostatic golden, electrostatic titanium , machine polish sliver, machine polish bronze, wooden grain color, and Fluorocarbon spraying.

4)Annual capacity : 120000TON

5)Quality : China Nation Standard GB/T 5237 2008 (advanced class)

6)Use: can be widely using aluminium window, door, curtain wall, hand railing , normal aluminium profile, decorative and industrial aluminium profile

7)Advantage: Famous Brand reasonable&market price, soonest delivery and good after sale- service

8)Type of package:protection foam+heat contracted plastic film. / wooden packing / Metal pallet or depand on clientspecial requirement.

9)Payment term:T/T:30% of total value as deposite should paid by T/T within 3 days when confirmation ,and the remaining sum should be paid by T/T before delivery.L/C: 100% at sight

10)Delivery Day: 15-30days

11)Honor : CHINA FAMOUS TRADEMARK, CHINA TOP BRAND, ISO9001-2000, CHINA SQUARE&ROUND COMMITTEE DNV

- Q: How much is aluminum freight per kilometer per ton?

- China Logistics Network: batch transportation more than 30 tons, 40 yuan per ton per ton

- Q: Is it possible to recycle aluminum profiles and use them again in construction projects?

- <p>Yes, aluminum profiles can be recycled and reused in construction. Aluminum is highly recyclable, and the recycling process requires significantly less energy compared to the production of new aluminum. Recycled aluminum maintains its properties, making it suitable for various construction applications. This practice not only conserves resources but also reduces waste and environmental impact.</p>

- Q: How do aluminum profiles contribute to daylighting strategies?

- Aluminum profiles contribute to daylighting strategies by being used in the construction of windows, doors, and skylights. These profiles are designed to be lightweight, durable, and have excellent thermal properties. They allow for larger glass panels, maximizing the amount of natural light that enters a space. Additionally, the profiles can be customized to accommodate different glazing options, such as low-emissivity coatings or solar control films, which help regulate heat gain and loss. Overall, aluminum profiles enhance daylighting strategies by promoting the use of natural light, reducing reliance on artificial lighting, and improving energy efficiency in buildings.

- Q: Can aluminum profiles be recycled indefinitely?

- Aluminum profiles possess the remarkable ability to be recycled endlessly. Unlike other materials, aluminum remains intact throughout the recycling procedure, allowing it to be melted and molded into fresh profiles without forfeiting its inherent qualities. Consequently, aluminum profiles enjoy an eternal life cycle. Opting for aluminum recycling proves to be an environmentally sustainable choice as it demands considerably fewer resources and energy than the production of new aluminum. Furthermore, the recycling process can be performed indefinitely without compromising the quality, rendering aluminum among the most frequently recycled substances globally.

- Q: Can aluminum profiles be used in agricultural machinery manufacturing?

- Aluminum profiles are indeed applicable in the manufacturing of agricultural machinery. Aluminum, being a lightweight and versatile material, offers numerous advantages for agricultural machinery. It possesses corrosion resistance, which is crucial for machinery exposed to harsh weather and farming chemicals. Furthermore, aluminum profiles have an exceptional strength-to-weight ratio, allowing the creation of robust and long-lasting machinery without unnecessary weight. The high thermal conductivity of aluminum also ensures efficient dissipation of heat, preventing machinery components from overheating. In addition, aluminum profiles are easily shaped, machined, and welded, providing flexibility in design and manufacturing processes. In summary, the incorporation of aluminum profiles in agricultural machinery manufacturing can lead to enhanced performance, fuel efficiency, and decreased maintenance costs.

- Q: Are aluminum profiles suitable for use in mining and construction equipment?

- Indeed, mining and construction equipment can benefit from the utilization of aluminum profiles. The unique properties of aluminum make it highly compatible with these industries. Firstly, its lightweight nature aids in reducing the overall weight of the equipment, facilitating easy transportation and maneuverability on construction sites or during mining operations. Moreover, this lightweight characteristic enhances fuel efficiency, thereby decreasing operational costs. Furthermore, aluminum profiles possess exceptional resistance to corrosion, a vital attribute for these industries, where equipment is frequently exposed to severe weather conditions and corrosive substances. This corrosion resistance guarantees the durability and longevity of the equipment, even in challenging environments. Additionally, aluminum profiles offer ease of fabrication and customization to cater to specific requirements. This adaptability in design permits the creation of intricate shapes and structures, enabling the construction of equipment with optimal strength and functionality. Moreover, the high thermal conductivity of aluminum profiles effectively dissipates heat generated during mining and construction operations. This property plays a crucial role in preventing overheating or damage to the equipment, ensuring efficient performance even in intense working conditions. In summary, the combination of lightweight, corrosion resistance, versatility, and thermal conductivity renders aluminum profiles a suitable choice for integration into mining and construction equipment.

- Q: Can aluminum profiles be used for creating lightweight furniture?

- Yes, aluminum profiles can be used for creating lightweight furniture. Aluminum is a lightweight and durable material, making it ideal for constructing furniture that is easy to move and transport. Additionally, aluminum profiles can be easily customized and shaped to create various furniture designs while maintaining their lightweight properties.

- Q: Can aluminum profiles be used for stage and event structures?

- Yes, aluminum profiles can be used for stage and event structures. Aluminum is a lightweight and durable material that is widely used in the construction of stage and event structures. It offers excellent strength-to-weight ratio, making it suitable for creating complex and versatile designs while ensuring structural stability. Additionally, aluminum profiles are easy to assemble, disassemble, and transport, making them a popular choice for temporary or portable stage and event structures.

- Q: This question asks for methods to protect aluminum profiles from corrosion and damage during the processes of transportation and storage.

- <p>To prevent corrosion and damage to aluminum profiles during transportation and storage, follow these guidelines: 1. Keep aluminum profiles dry and clean. Moisture and dirt can accelerate corrosion. 2. Use protective packaging, such as plastic wrap or padded covers, to shield profiles from physical damage and moisture. 3. Store profiles in a cool, dry place away from direct sunlight and corrosive substances. 4. Stack profiles with appropriate padding between layers to prevent scratching. 5. Avoid overloading during transportation and ensure secure fastening to prevent movement and potential damage. 6. Regularly inspect stored profiles for signs of corrosion or damage and address any issues promptly.</p>

- Q: This question asks about the various types of aluminum profiles that are specifically used for the purpose of insulating exterior walls.

- <p>Aluminum profiles for exterior wall insulation are crucial for thermal efficiency and structural integrity. Common types include: 1. <strong>Aluminum Cladding Profiles</strong>: These cover the insulation and provide a weather-resistant barrier. 2. <strong>Aluminum Insulation Fin Profiles</strong>: Used to create a gap for insulation material between the wall and the cladding. 3. <strong>Aluminum Casing Profiles</strong>: These encase the insulation, providing a finished look and additional protection. 4. <strong>Aluminum Angle Profiles</strong>: Used for corners and edges to maintain structural integrity. 5. <strong>Aluminum Trim Profiles</strong>: For finishing touches and to cover gaps or seams. Each type serves a specific function in the insulation system, ensuring energy efficiency and a durable exterior wall construction.</p>

Send your message to us

10mm Anodized Bronze Color Aluminum Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords