Amoco Geotextile Fabric - Polyester Staple Fiber Needle Punched Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products overview:

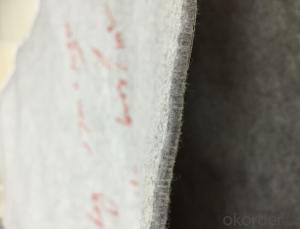

Shandong yongrun nonwoven geotextile polyester staple fiber acupuncture is made of high quality pet staple fiber for raw materials, after carding spread nets acupuncture and processed. Performance characteristics: it has good flexibility, acid and alkali resistance, corrosion resistance, ageing, the intensity is high, the dimension stability, and have good water, filtering, isolation performance, construction is convenient, etc.

Use function:

1, water conservancy project: seawalls, JiangDi river, lake, standard engineering; Reservoir reinforcement engineering; Surround with engineering; reclamation The rescue flood control.

2, the airport highway, rail project; The soft foundation reinforcement; Slope protection; Road surface reflection; Crack "structure layer; Drainage system; Green belt.

3, power plant project: nuclear power plant project based; Thermal power ash dam projects; Hydropower station.

4, port channel engineering: port wharf engineering; Lock engineering; Channel regulation engineering.

The product specification:

Width: 2-7 m, g: 100 g to 800 g/m2.

- Q: How do geotextiles help with soil confinement in erosion control tubes?

- Geotextiles provide soil confinement in erosion control tubes by acting as a barrier that holds the soil in place, preventing its movement and erosion. They create a stable environment for the soil, allowing vegetation to grow and roots to anchor the soil, further enhancing erosion control efforts.

- Q: How do geotextiles aid in the reduction of pore water pressure?

- Geotextiles aid in the reduction of pore water pressure by providing a barrier that allows water to flow through while preventing the movement of fine soil particles. This helps to maintain the stability of soil structures, as the geotextile acts as a filter, allowing excess water to drain away and reducing the build-up of pressure within the soil.

- Q: Geomembrane and geotextile difference?

- Geotextile is woven up the "cloth", geomembrane is based on the geotextile paste a layer of impermeable membrane.

- Q: Geotextile what are the specifications of the ah?

- Geotextile is first divided into short wire geotextile and filament geotextile. Their specifications generally according to the weight to count, small equipment, geotextiles are mostly between 80g-380g, and now some mature domestic enterprises generally can do between 100g-1500g short wire and filament geotextile. How many grams of this can be customized between. It should be noted that the same specifications of the short wire geotextile price than the filament geotextile to 30% cheaper, but the technical strength index than the long geotextile cloth nearly 50%.

- Q: How do geotextiles help with soil reinforcement in mechanically stabilized earth walls?

- Geotextiles help with soil reinforcement in mechanically stabilized earth walls by providing a strong and stable support system. They act as a barrier between the soil layers, preventing erosion and maintaining the integrity of the wall. The geotextiles distribute the load of the soil evenly, reducing the potential for settlement or failure. Additionally, they enhance the overall stability of the structure by increasing the friction between the soil layers, improving the resistance to lateral forces.

- Q: Geotextile types and role of geotextiles which types, respectively, what role, filament geotextile, short geotextile, composite geotextile, respectively, what role? More

- 1, acupuncture non-woven geotextile, specifications 100g / m2-1000g / m2 between any choice, the main raw material is the use of polyester staple fiber or polypropylene staple fiber, made by acupuncture, the main purposes are: river, sea, lake Embankment slope protection, reclamation, wharf, ship lock flood control and other projects, is through the filter to play a soil and water conservation and effective way to prevent piping. Second, acupuncture non-woven fabrics and PE film composite geotextile, specifications have a cloth a film, two cloth a film, the largest width of 4.2 meters The main raw material is to use polyester staple fiber acupuncture non-woven, PE film through the composite , The main purpose is anti-seepage, apply to railways, highways, tunnels, subways, airports and other projects. Third, non-woven and woven composite geotextile, a variety of non-woven and polypropylene filament woven composite, non-woven and plastic woven composite, for the basis of reinforcement, adjust the permeability coefficient of the basic engineering facilities. Features: light weight, low cost, corrosion resistance, with a filter, drainage, isolation, enhance the excellent performance. Use: widely used in water conservancy, electricity, mines, roads and railways and other geotechnical projects: l, soil separation of the filter material; 2, reservoirs, mine mineral processing of drainage materials, high-rise building drainage materials; Of the anti-erosion material; geotextile features 1, high strength, due to the use of plastic fibers, in dry and wet state can maintain sufficient strength and elongation. 2, corrosion-resistant, in different pH of the soil and water can be long-term corrosion resistance. 3, good water permeability between the fiber gap, it has a good water permeability. 4, good microbial resistance to micro-organisms, insects are not damaged. 5, construction convenience

- Q: How are geotextiles manufactured?

- Geotextiles are typically manufactured using a process called needle punching. This involves mechanically interlocking synthetic fibers together to create a strong and durable fabric. The fibers are first carded, meaning they are aligned and separated, before being fed through a machine that punches them with barbed needles. These barbs entangle and interlock the fibers, creating a stable fabric structure. Further processes such as heat setting, calendaring, and coating may be applied to enhance the geotextile's properties, such as increasing its resistance to UV degradation or improving its filtration capabilities.

- Q: Garage top back to the soil before the drainage board geotextile take what role

- The top surface of the drainage board glue a layer of geotextile filter to prevent the passage of soil particles, so as to avoid drainage channel obstruction of the drainage channel, said white is to do a filter layer, the water discharged to the designated location, the traditional process is Block ah, stone ah, what do the water layer, and now with the drainage board is not the reason for the stone is the drainage board is plastic, light weight, can reduce the load of the building. Manufacturers of drainage board geotextile waterproof board

- Q: What causes the geotextile aging phenomenon

- Gundam has the characteristics of the product we are all obvious, both in the highway, dams, railways and many other occasions have a very strong product features, and the performance is very outstanding, geotextile is an irreplaceable geotechnical material. Although the geotextile has unparalleled advantages, but the product is not perfect that any product has more or less problems or less, geotextile is the same, its aging problem has been with us, then in the end what causes Geotextile aging? Geotextile aging problem refers to the geotextile in the sun by the smell, temperature changes, biological erosion, chemical corrosion, moisture and other external factors, so that the geotextile strength and performance gradually weakened, loss of seepage effect. UV radiation intensity changes with the intensity of solar radiation, geotextile aging speed with the intensity of UV radiation and speed. Synthetic polymer polymer is concerned, the sun radiation is the main factor in the degradation of polymer degradation. UV radiation in the sun is the most important factor in the aging of the fabric. The ultraviolet radiation causes the polymer to produce a photooxidative decomposition reaction, especially ultraviolet light at a wavelength of 290 to 400 mPm, which has a significant decomposition effect on the polymer , Because the geotextile in the range of ultraviolet light energy is higher than the polymer chemical steamed broken the required energy, so the polymer material aging is very obvious.

- Q: Geotextile construction inspection batch ye do?

- Plastic woven category: the same formula, the same specifications of 100,000 square meters of products for a group; less than 100,000 square meters, the actual number of a batch. Non-woven geotextiles: the same frequency of production of the same specifications for a number of products; batch volume can be accumulated 100 volumes for a group, but the week is still less than 100 volumes of output, then with a group of output. Plastic woven cloth: batch as a unit, each batch of products randomly take 3 volumes as a sample geotextile categories: each batch of products randomly selected 2% to 3%, but not less than 2 volumes. Sample requirements: the whole width, length 3m or more, the sample can be rolled up, but can not be folded.

Send your message to us

Amoco Geotextile Fabric - Polyester Staple Fiber Needle Punched Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords