Pre-painted Aluzinc Steel Coil Used for Industry with The Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-painted Aluzinc Steel Coil Used for Industry

1.Structure of Pre-painted Aluzinc Steel Coil Description

With aluzinc steel as base metal, after degrease and chemical treatment and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted aluzinc steel. Pre-painted aluzinc steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

2.Main Features of Pre-painted Aluzinc Steel Coil

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

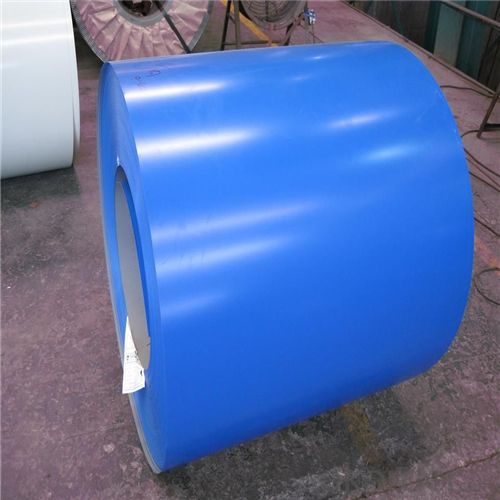

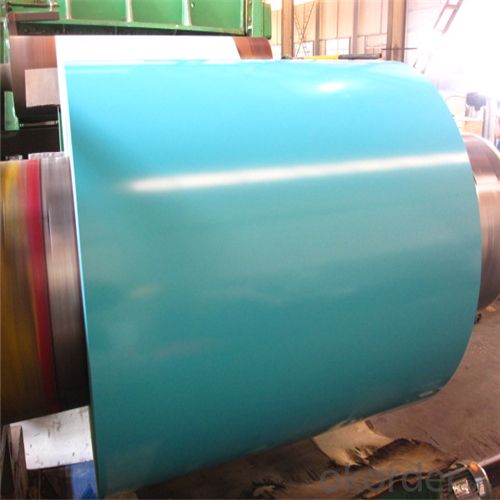

3. Pre-painted Aluzinc Steel Coil Images

4. Pre-painted Aluzinc Steel Coil Specification

Pre-painted Aluzinc Steel Coil | |

Thicknenss | 0.18mm-1.5mm |

Width | 900-1250mm |

Coating mass | 30-185g/㎡ |

Paint | PE, PVDF, PU |

Color | RAL Scale |

Coil weight | 3-7mt |

Coil inner diameter | 508 or 610mm |

5.FAQ of Pre-painted Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test.

Sincerely welcome to contact us for the future details if any item interest you ,and we will make every effort to assure that your requirements will be satisfied ,and we hope to establish long-term business relations with you on the basis of the equality and mutual benefit.

- Q: Just wondering how good are forge steel screw drivers, tool boxes(organisers) and pliers are, as screw fix are having a january sale, and looking to add to my tool collection. Thanks in advance

- Forge Steel

- Q: What are the different methods of coil rewinding for steel coils?

- There are several different methods of coil rewinding for steel coils, including manual rewinding, semi-automatic rewinding, and fully automatic rewinding. In manual rewinding, the coils are rewound by hand using a winding machine or tool. Semi-automatic rewinding involves the use of a machine that assists with the rewinding process, but still requires some manual intervention. Fully automatic rewinding, on the other hand, involves the use of advanced machinery that can automatically rewind the steel coils without any manual intervention. These different methods offer varying levels of efficiency, speed, and precision in the coil rewinding process.

- Q: What are the different methods of uncoiling steel coils?

- There are several different methods of uncoiling steel coils, depending on the specific requirements and equipment available. Some common methods include: 1. Uncoiling by hand: This method involves manually unwinding the coil by hand using a bar or rod inserted through the inner diameter of the coil. It is typically used for smaller coils or when other methods are not available. 2. Uncoiling with a mandrel: A mandrel is a cylindrical tool that supports the inner diameter of the coil and allows it to rotate freely. The coil is placed on the mandrel, which is then rotated to unwind the steel. 3. Uncoiling with a decoiler machine: Decoiler machines are designed specifically for uncoiling steel coils. They typically consist of a mandrel or drum that holds the coil, along with a motorized mechanism that rotates the coil and controls the speed of unwinding. Decoilers can handle larger and heavier coils, making them suitable for industrial applications. 4. Uncoiling with a straightener-feeder: This method is often used when the steel coil needs to be straightened and fed into a production line simultaneously. The coil is passed through a set of straightening rollers to remove any curvature, and then fed into the subsequent processing equipment. 5. Uncoiling with a recoiler: Recoilers are used when the steel coil needs to be rewound into a new coil. The original coil is uncoiled using one of the aforementioned methods, and then the steel is rewound onto a new mandrel or drum to create a smaller coil. It is important to note that the choice of uncoiling method depends on various factors such as the size and weight of the coil, the desired level of automation, and the specific production requirements.

- Q: What are the dimensions of a typical steel coil?

- The dimensions of a typical steel coil can vary depending on the manufacturer and specific application, but common dimensions include thicknesses ranging from 0.015 inches to 0.5 inches, widths between 24 inches and 72 inches, and coil weights ranging from a few thousand pounds to over 50,000 pounds.

- Q: What are the different grades of steel used in coil manufacturing?

- There are various grades of steel used in coil manufacturing, including low carbon steel, medium carbon steel, high carbon steel, stainless steel, and alloy steel. These grades differ in their composition, strength, and corrosion resistance, allowing manufacturers to choose the most suitable grade for specific applications and requirements.

- Q: How do steel coils contribute to thermal insulation in buildings?

- Steel coils do not directly contribute to thermal insulation in buildings. Steel coils are typically used in the construction of structures and for various applications, but they do not have inherent thermal insulation properties. Other materials such as insulation boards, panels, or foams are commonly used for thermal insulation in buildings.

- Q: How do steel coils contribute to the marine industry?

- Steel coils contribute to the marine industry by being used in the construction of ships and offshore structures. They are essential for manufacturing various components, such as hulls, decks, beams, and structural supports. Steel coils provide strength, durability, and corrosion resistance, ensuring the longevity and safety of marine vessels and infrastructure. Additionally, steel coils are used for the production of marine equipment, including cranes, winches, and anchor chains, further enhancing the efficiency and functionality of the marine industry.

- Q: i would like to make a dmascus steel knife, i have the cable but im not sure if its damascus steel or not, how do i tell? and if it isnt damascus steel how do i make a bar of it?

- Here's what you need, the cable should be a minimum of 9/16 with large wires. You need some borax (20 mule team from the store). A good hot coal, coke, or gas forge. If the cable has fiber rope in the center it will need to be removed. Fuse the ends of the cable to keep them from coming apart. I use my welder and while I'm at it I weld a handle to make it easier. Heat it in the forge when the forge is properly heated, rotate it. Some people will burn the oil out, but I've found that the forge does that just fine. Rotate the cable while it's heating. When it begins the turn red pull it out and sprinkle the borax over it, don't hold back use a lot. It will begin to melt and bubble into the steel. Put the cable back in the forge, rotate and watch. This is the critical part. When the steel starts to turn from orange/yellow to almost yellow/white take it out and lightly (I use a 2lb hammer) begin hammering the cable into a square or rectangle. If you do it right you'll notice that it will begin to fight the hammer, that's when you know the weld it taking place. You'll have to repeat the process down the length of the cable. Once you have the billet made you can begin the process of shaping the edge and tang. Once you have it shaped, follow proper forge procedure then grind all the yuck off and finish shaping. Then harden and temper and finish it out. Good luck. I almost forgot a very important part. Befor you start hammering put the cable in a vice while at welding temp (if you are strong you can use a couple of plyers) and twist it tight. On the next heat hold the cable in your left and and lay it on the anvil. Concentrate on your light hammer blows being on your side of the cable. This forces the cable strands together. If you are using smaller cable like 9/16 you can double the cable up and weld two peices together, it is easier and makes for a prettier blade. Doing this you don't have to worry about twisting the cable and you can hit it much harder to start with.

- Q: How are steel coils used in the production of rail tracks?

- Steel coils are used in the production of rail tracks as they are a primary raw material for manufacturing the rails. These coils are first processed to form the desired shape and dimensions of the rail tracks, which are then cut, welded, and shaped to create the individual rail sections. The steel coils provide the strength, durability, and flexibility necessary for the tracks to withstand heavy loads, extreme weather conditions, and constant use.

- Q: How do steel coil manufacturers ensure fair pricing?

- Steel coil manufacturers ensure fair pricing through various measures. Firstly, they conduct thorough market research to understand the current industry trends, demand-supply dynamics, and competitor pricing. This helps them determine a competitive yet fair pricing strategy that aligns with market standards. Secondly, steel coil manufacturers consider the cost of raw materials, production, and operational expenses to determine a reasonable base price. They also factor in economies of scale, as larger production volumes can lead to lower costs per unit. Additionally, steel coil manufacturers often establish long-term partnerships with suppliers to ensure a stable and consistent supply of raw materials at fair prices. This allows them to maintain a reasonable cost structure and minimize price fluctuations. Furthermore, these manufacturers strive for transparency in pricing by providing detailed quotations that break down the cost components. This helps customers understand the factors contributing to the final price and ensures fairness in the pricing process. To enhance fairness, steel coil manufacturers also consider the specific requirements of their customers. They may offer customized pricing based on factors such as order volume, delivery timelines, and value-added services. This approach ensures that each customer receives a price that is commensurate with their unique needs and requirements. Overall, steel coil manufacturers ensure fair pricing by conducting market research, considering cost factors, maintaining transparent pricing practices, and offering customized pricing options. By doing so, they aim to create a fair and mutually beneficial pricing environment for both themselves and their customers.

Send your message to us

Pre-painted Aluzinc Steel Coil Used for Industry with The Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords