Aluminum Siding Profiles - AA3XXX Mill-Finished Aluminum Coils D.C Quality for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

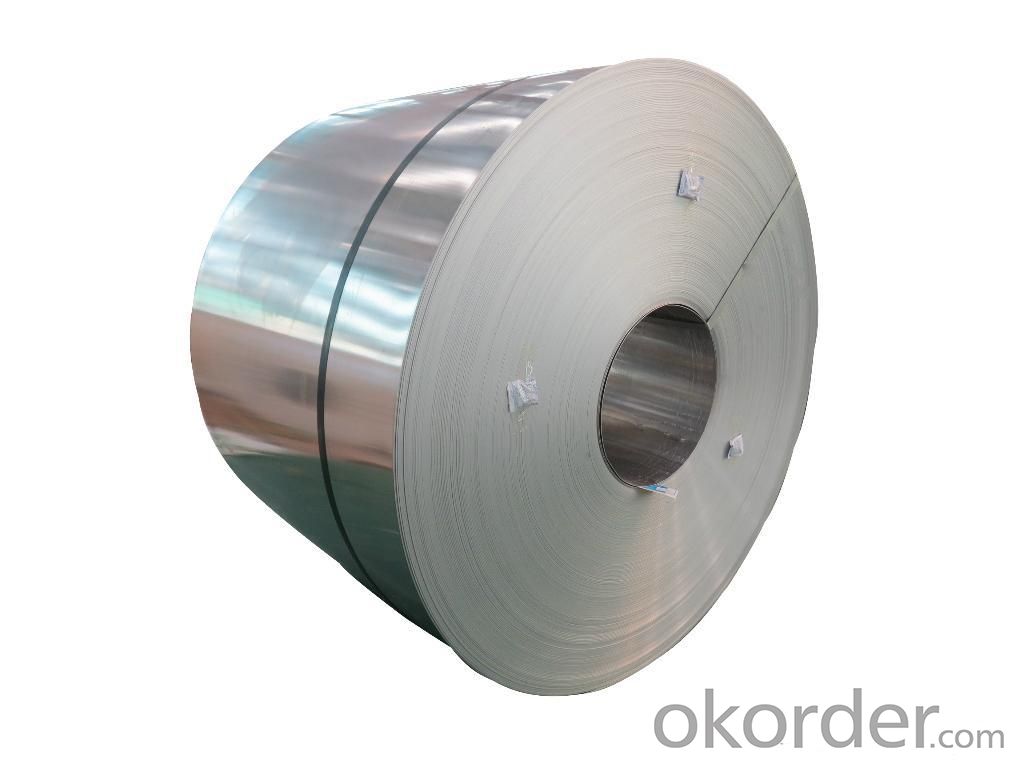

1.Structure of AA3xxx Mill-Finished Aluminum Coils D.C Quality Used for Construction Description

AA3xxx Mill-Finished Aluminum Coils D.C Quality Used for Construction has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

AA3xxx Mill-Finished Aluminum Coils D.C Quality Used for Construction is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of AA3xxx Mill-Finished Aluminum Coils D.C Quality Used for Construction

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

3.AA3xxx Mill-Finished Aluminum Coils D.C Quality Used for Construction Images

4.AA3xxx Mill-Finished Aluminum Coils D.C Quality Used for Construction Specification

Alloy | AA3xxx (AA3003, AA3105 etc.) |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of AA3xxx Mill-Finished Aluminum Coils D.C Quality Used for Construction

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test AA3xxx Mill-Finished Aluminum Coils D.C Quality Used for Construction.

B.When will you deliver the products?

AA3xxx Mill-Finished Aluminum Coils D.C Quality Used for Construction will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: Can aluminum profiles be used for skylights?

- Skylights can indeed utilize aluminum profiles. The durability, strength, and corrosion resistance of aluminum make it a popular choice for skylight frames. Its lightweight yet robust nature ensures the skylight glass is adequately supported and guarantees long-lasting performance. Furthermore, aluminum profiles can be effortlessly tailored and molded to meet specific design needs, enabling a wide range of skylight styles and sizes. Incorporating aluminum profiles in skylights also offers exceptional thermal insulation, promoting energy efficiency by minimizing heat transfer and condensation. In summary, aluminum profiles are a dependable and pragmatic choice for skylight construction.

- Q: Do aluminum profiles require any special maintenance?

- Aluminum profiles do not require any special maintenance. Aluminum is a durable and low-maintenance material that is resistant to corrosion, rust, and weathering. Unlike other materials such as wood or steel, aluminum profiles do not need to be regularly painted, stained, or treated to maintain their appearance or functionality. Additionally, aluminum is lightweight, making it easy to handle and install. However, it is important to keep the aluminum profiles clean by regularly removing dirt or debris with a mild detergent and water solution. This will help to preserve the aesthetic appeal and longevity of the profiles. Overall, aluminum profiles are a convenient and hassle-free option for various applications, as they do not require any special maintenance.

- Q: What are the advantages of using aluminum profiles in the oil and gas industry?

- Using aluminum profiles in the oil and gas industry offers numerous benefits. First and foremost, aluminum profiles boast an exceptional strength-to-weight ratio. This means they provide excellent structural integrity while remaining lightweight, a crucial factor when transporting and installing equipment in different locations. Moreover, the lightweight nature of aluminum profiles reduces the strain on structures and equipment, resulting in energy savings and enhanced efficiency. Secondly, aluminum profiles exhibit remarkable resistance to corrosion. Given that the oil and gas industry often operates in harsh environments with exposure to saltwater, chemicals, and extreme temperatures, the natural oxide layer of aluminum acts as a protective barrier, ensuring durability and preventing corrosion. This corrosion resistance significantly reduces maintenance and replacement costs throughout the equipment's lifespan. Furthermore, aluminum profiles are non-magnetic, making them ideal for applications where magnetic interference is a concern. In the oil and gas industry, precision and accuracy are paramount, and the non-magnetic properties of aluminum profiles ensure that equipment operates without any electromagnetic interference, guaranteeing data accuracy and reliable performance. Additionally, aluminum profiles can be easily fabricated and customized to meet specific requirements. They can be extruded into various shapes, sizes, and configurations, providing endless design possibilities. This manufacturing flexibility makes aluminum profiles highly versatile, allowing them to be utilized in a wide range of applications within the oil and gas industry, such as pipe racks, platforms, support structures, and access systems. Lastly, aluminum is an environmentally friendly and sustainable material. It is 100% recyclable without losing its properties, making it an ideal choice for the oil and gas industry, which increasingly focuses on reducing its carbon footprint. The recyclability of aluminum also contributes to cost savings and resource conservation. In conclusion, the advantages of using aluminum profiles in the oil and gas industry encompass their high strength-to-weight ratio, corrosion resistance, non-magnetic properties, easy fabrication, and recyclability. These characteristics make aluminum profiles a dependable and cost-effective solution for various applications within this industry.

- Q: Aluminum prices are calculated by the meter, or how to quote the ah?

- Yes, for example, today's aluminum price, 10340+ processing fee 4000=14340, in addition to 1000 is equal to 14.34 yuan /KG

- Q: Can aluminum profiles be used in the production of industrial robots?

- Yes, aluminum profiles can be used in the production of industrial robots. Aluminum is a lightweight and durable material that offers several advantages for constructing robotic systems. It has a high strength-to-weight ratio, making it suitable for building rigid and reliable robot structures. Aluminum profiles can be easily machined, allowing for precise and intricate designs to be created for various robot components such as frames, arms, and joints. Additionally, aluminum is corrosion-resistant, which is beneficial in industrial settings where robots may be exposed to harsh environments or chemicals. Overall, aluminum profiles provide a cost-effective and versatile solution for manufacturing industrial robots.

- Q: How do aluminum profiles perform in wind-resistant structures?

- Aluminum profiles are known for their excellent performance in wind-resistant structures. Due to their inherent strength and durability, they are able to withstand high wind pressures and maintain structural integrity. The lightweight nature of aluminum makes it an ideal material for constructing wind-resistant structures as it reduces the overall load on the building without compromising its strength. Aluminum profiles have high tensile strength and are resistant to corrosion, making them suitable for withstanding harsh weather conditions, including strong winds. They also have a high stiffness-to-weight ratio, meaning they can effectively distribute the wind load and minimize deflection. This characteristic is essential in wind-resistant structures as it helps to prevent excessive movement and ensures the safety of the building and its occupants. Furthermore, aluminum profiles can be easily fabricated and customized, allowing for the creation of complex and innovative designs. This flexibility in design enables architects and engineers to optimize the aerodynamics of the structure, further enhancing its resistance to wind forces. Additionally, aluminum profiles can be combined with other materials, such as glass or composite panels, to create a more robust and efficient wind-resistant system. Overall, aluminum profiles are highly reliable and efficient in wind-resistant structures. Their strength, lightweight nature, corrosion resistance, and flexibility in design make them an excellent choice for constructing buildings that can withstand strong winds and ensure the safety and longevity of the structure.

- Q: Which price is expensive for aluminum profiles 6063-T6 and 6063-T5?

- Alloy number: China's current general is the United States Aluminum Association "Aluminium Association" number. We giveExamples are as follows: 1070-H14 (pure aluminum)2017-T4 (heat treatment alloy)3004-H32 (non heat treated alloy)

- Q: Are aluminum profiles suitable for playground equipment?

- Yes, aluminum profiles are suitable for playground equipment. Aluminum is a lightweight, durable, and corrosion-resistant material, making it ideal for use in playground equipment. It provides stability and strength while also being easy to work with and maintain. Additionally, aluminum profiles can be shaped into various forms, allowing for creative and innovative playground designs.

- Q: What are the different types of corner connectors used with aluminum profiles?

- There are several different types of corner connectors used with aluminum profiles, including corner brackets, corner blocks, T-slot corner connectors, and corner gussets. These connectors help to create strong and stable joints between aluminum profiles, allowing for the construction of various structures and frameworks.

- Q: For example, 80*80 square tube 2.0mm thick. Or 38*25 square tube, 0.8mm thick, how to calculate the rice weight? Please tell the specific formula, urgent

- Length (you want to count the number of meters) * width (square tube expansion size) * high (wall thickness) * density (you this square tube material density, aluminum alloy gold density is more complex, generally in 2650~2750Kg/m3)1m * (0.08 * 4) * * 2750kg/m 0.002=0.00064m fand fand =1.76KGThen you 80*80 wall thickness of 2 square tubes, one meter is 1.76 kilogramsWindows and doors exchange group (228021644) hope to help you!

Send your message to us

Aluminum Siding Profiles - AA3XXX Mill-Finished Aluminum Coils D.C Quality for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords