Aluminum Sheets for Sale Brisbane - Competitive Price Aluminum Sheet for Roofing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

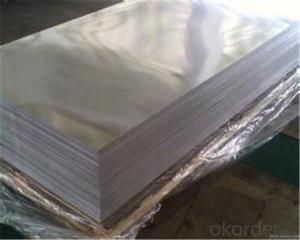

Specifications of Aluminium Sheet

Alloy | Thickness(mm) | Width(mm) | Length(mm) | Temper | DC or CC | |

1050,1060,1070,1100, 1235 | 0.2-3.0 | 300-1850 | 1000-8000 | O,H12,H22,H14,H24,H16,H26,H18,H32 | DC, CC | |

3.0-150 | 900-1900 | H112,H111 | DC | |||

3003,3004,3105,3005 | 0.2-3.0 | 300-1850 | 1000-8000 | O,H12,H22,H14,H24,H16,H26,H18,H32 | DC, CC | |

3.0-150 | 900-1900 | H112,H111 | DC | |||

5052,5083,5754,5005 | 0.2-3.0 | 300-1850 | 1000-8000 | O,H12,H22,H14,H24,H16,H26,H18,H32,H36 | DC | |

3.0-150 | 900-1900 | H112, H111 | DC | |||

6061,6063 | 0.5-3.0 | 300-1500 | 1000-6000 | T6,T321 | DC, | |

width and length:to cut as your requirement thickness:0.15-0.3m Tensile Strength:130~150MPa .Yield Strength:130-145.Elongation:≥2%,Earing Rate:≤2%.There are no stop marks or pinch marks on the surface of aluminum sheets.

There are no water stains or blisters on the surface.

Mainly in Construction, decoration, PCB materials, cover material, LCD back panel, refrigeration, air conditioner, automobile, etc

The Main Features of Aluminium Sheet:

1.Superior quality of raw material.

2.Reasonable and stable chemical composition.

3.Accurate tolerance.

4.Goode mechanical property.

5.We have the certificate of ISO9001.

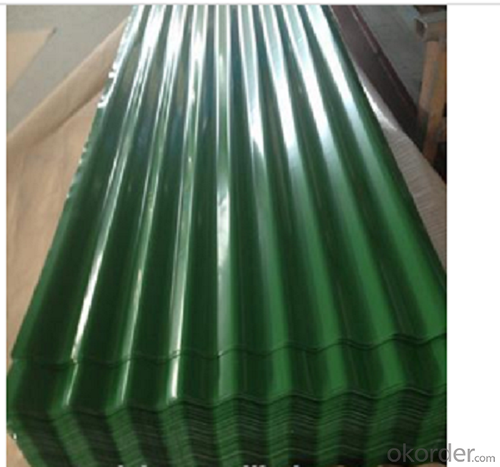

The Images of Aluminium Sheet:

FAQ:

1. Minimum Order Quantity? MOQ is 25 tons, your quantity is ok, the aluminium foil sample is available. |

2. What kind of terms of payment? T/T, L/C,D/A,D/P,Western Union are available. |

3. What grams of the product can you offer? Our products can be customized according to your requirment |

4.Can you do Customization & Reproduction if I provide a photo? Yes, we do Customization & Reproduction service, please check the details and sample above. You need to send the pictures to our email, tell us the specification you want, then we will quote you exact price. We will take photos for you check. |

5. Does the packaging safe and arrive in good conditions? Yes, Safe Packing guarrantee, all the products will arrive your door under good conditions. We response to problem of shipping if there unfortunately is. |

6. How long does it usually take to deliver the product? We'll make the shipment to you immediately. It will take about 18 to 40 days arrive worldwide. Accurate delivery time depends on the specific quantity |

7.Is drop shipping abailable? Yes, it is, we can send to worldwide. |

- Q: Is it possible to incorporate windows made from recycled materials into a construction project?

- <p>Yes, you can use windows made from recycled materials in your project. There are eco-friendly windows available that are manufactured using recycled glass or other sustainable materials. These windows can offer similar performance to traditional ones while reducing the environmental impact of your construction. It's important to check the quality and certifications of the recycled windows to ensure they meet your project's requirements.</p>

- Q: Can aluminum sheet be used for electrical bus bars?

- Yes, aluminum sheet can be used for electrical bus bars. Aluminum is a commonly used material for bus bars due to its high electrical conductivity, lightweight nature, and cost-effectiveness.

- Q: Would you please tell me what putty to use on the aluminium board, what kind of putty, and the painting process?

- You can also consider adding primer or putty, and then spray paint.In summary, adhesion of the topcoat is reinforced with an agent.

- Q: Solid aluminum or solid wooden boxes-no glass top. Would glass make the temperature rise more quickly? (ie Solar)? Thanks.Joseph

- If all of the heat transfer is from the sun through the open top, a wooden box would keep the heat in, acting as an insulator. The aluminum box would quickly radiate away any trapped heat. If the heat is coming in through the walls, then aluminum would conduct the heat better. A glass top would definitely allow the sun's energy in while trapping the heat. That is how a greenhouse works! The aluminum vs. wood discussion still holds, wood is better in this situation.

- Q: Can aluminum sheets be used for sound insulation?

- Yes, aluminum sheets can be used for sound insulation. Aluminum has good soundproofing properties due to its high density and ability to reflect sound waves. When used as a barrier or in combination with other sound-absorbing materials, aluminum sheets can effectively reduce noise transmission.

- Q: Are aluminum sheets suitable for use in cryogenic environments?

- Yes, aluminum sheets are suitable for use in cryogenic environments. Aluminum has excellent thermal conductivity, low density, and good mechanical properties at low temperatures, making it an ideal choice for applications in cryogenic environments. Additionally, aluminum has a low coefficient of thermal expansion, which allows it to maintain its structural integrity even under extreme temperature fluctuations.

- Q: How do I clean and maintain aluminum sheets?

- In order to clean and maintain aluminum sheets, there are several steps that can be followed: 1. To begin, one should prepare a cleaning solution by combining warm water with a mild detergent or dish soap in a bucket or sink. It is important to avoid using harsh chemicals or abrasive cleaners as they can cause damage to the aluminum. 2. Next, immerse a soft sponge or cloth into the cleaning solution and gently scrub the surface of the aluminum sheets. It is necessary to ensure that the entire surface is covered, with special attention given to any stains or dirt build-up. 3. In the case of stubborn stains or grime, a non-abrasive brush or toothbrush can be used to scrub the affected areas. However, caution should be exercised to prevent applying excessive pressure, as this may result in scratching the aluminum. 4. Following the cleaning process, the sheets should be thoroughly rinsed with clean water to eliminate any residue from the cleaning solution. It is important to ensure that all soap is completely rinsed off. 5. Once rinsed, a clean and dry cloth should be used to remove any excess water and dry the aluminum sheets. This step aids in preventing water spots or stains from forming. 6. To preserve the shine and condition of the aluminum, a thin layer of aluminum polish or wax can be applied. It is advisable to follow the manufacturer's instructions for the best outcomes. 7. Regular inspection of the aluminum sheets is recommended to detect any signs of damage, such as dents, scratches, or corrosion. If any issues are noticed, they should be promptly addressed to prevent further harm. It is crucial to handle aluminum sheets with care to avoid damage. The use of abrasive materials, sharp objects, or harsh chemicals that can scratch or corrode the surface should be avoided. Regular cleaning and maintenance will assist in preserving the appearance and prolonging the lifespan of the aluminum sheets.

- Q: What precautions should be taken while handling aluminum sheets to ensure safety?

- <p>When working with aluminum sheets, it's important to take certain safety measures. Always wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and a dust mask to protect against sharp edges and metal dust. Ensure good ventilation to avoid inhaling aluminum dust, which can be harmful. Use proper tools designed for metal work to prevent accidents. Keep the work area clean and free from clutter to minimize trip hazards. Be cautious of electrical hazards if using power tools, and ensure all tools are in good working order. Finally, be aware of the fire hazard potential of aluminum, especially when cutting or welding, and have fire extinguishers readily available.</p>

- Q: What is the typical bend radius for aluminum sheets?

- The typical bend radius for aluminum sheets depends on various factors, such as the alloy, thickness, and temper of the sheet. However, a general guideline for the minimum bend radius for aluminum sheets is typically around 1 to 1.5 times the material thickness. For example, if you have a 1mm thick aluminum sheet, the minimum bend radius would be around 1 to 1.5mm. It is important to note that this is just a general guideline, and the specific bend radius may vary depending on the specific application and requirements. It is advisable to consult with a professional or reference material specifications for precise bend radius recommendations for a specific aluminum sheet.

- Q: what were the cinergy field (riverfront stadium, cincinnati, oh) seats made of? were they metal or aluminum? i know they were silver under the red paint...

- The stadium opened in 1970, so that would be aluminum.

Send your message to us

Aluminum Sheets for Sale Brisbane - Competitive Price Aluminum Sheet for Roofing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords