Sublimation Aluminum Sheets Quotes - Aluminum Sheet 1050,1100,5005,5754,8079 for Decorative Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.specification

material: | Alloy or not | ||

thickness: | 1,3 series | 0.3-9.5mm | |

5series | 0.5-150mm | ||

6 series | 5-150mm | ||

7series | More than 6mm | ||

width: | 1,3 series | 900-1500mm | |

5 series | 900-1500mm | ||

6 ,7series | As your request | ||

Circulation size: (width*length)

| 1220*2440mm 1250*2500mm 1500*3000mm 1000*2000mm | ||

Usage : | Boat, plane, building, packaging, machine…. | ||

MOQ | 3 tons | ||

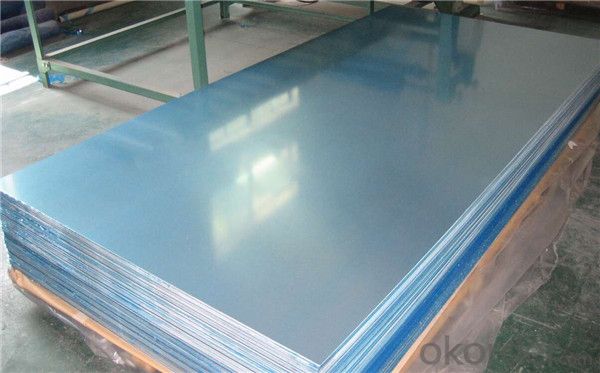

2.product show

Dear Customer, why do I have the confidence to let you buy our product ?

♥strict chemical composition , good hardness high safety performance

♥Oxide film thickness, corrosion resistance

♥Standard aluminum closed time, no rust

♥smooth surface, no burrs

Our VS others

3.shipping:

20~25 working days & send samples:2--3 days after received your advance payment

Mode of transport | advantage | disadvantage | advice |

Express delivery | Fast(3—6days ),door to door wide area coverage | Volume & weight restricted | Good for small cargo |

Sea transpoet | Cheapest volume unlimited | Long sailing time influenced by climate and port conditions | Bulk cargo loose time |

Air transport | Fast(4—5days) simple packaging | The most expensive volume restrict | For valuable cargo urgent need |

Railway | Big volume more expensive | Tracking difficult transit organization may cause delay | Preferred in central Asia |

4.Product photos

- Q: Can aluminum sheets be used for curtain walls?

- Yes, aluminum sheets can be used for curtain walls. Aluminum is a popular choice for curtain wall systems due to its lightweight, durability, and flexibility in design. It offers excellent structural integrity, weather resistance, and thermal performance, making it suitable for creating modern and aesthetically appealing curtain wall facades.

- Q: Are aluminum sheets suitable for high-pressure environments?

- In high-pressure environments, aluminum sheets are generally unsuitable due to their relatively low strength-to-weight ratio compared to other materials. Consequently, there is a potential for deformation or failure under high pressure, posing safety risks. Moreover, aluminum's structural integrity is further compromised in these situations due to its relatively low melting point. Therefore, materials like steel or titanium, which offer greater strength and resistance to deformation, are typically preferred in such environments.

- Q: What are the advantages of using aluminum sheets in the transportation industry?

- The utilization of aluminum sheets in the transportation sector offers numerous benefits. To begin with, aluminum, being a lightweight material, proves to be advantageous in vehicles by reducing fuel consumption and increasing overall efficiency. This attribute is particularly significant in industries like aviation and automotive, where weight reduction plays a crucial role in enhancing performance. Furthermore, aluminum exhibits exceptional resistance to corrosion, which is pivotal in the transportation field where vehicles are exposed to diverse environmental conditions such as rain, snow, and road salt. The implementation of aluminum sheets helps prolong the lifespan of vehicles and diminishes the maintenance costs linked to corrosion-related problems. Moreover, aluminum is highly recyclable, making it a more sustainable option when compared to other materials. The transportation industry is increasingly prioritizing sustainability, and the utilization of aluminum sheets aligns with these objectives. Recycling aluminum consumes significantly less energy than producing it from raw materials, leading to reduced carbon emissions and energy consumption. Additionally, aluminum offers excellent formability and versatility, enabling it to be easily shaped into various forms and sizes. This characteristic allows manufacturers to design structures that are lightweight yet robust. This design flexibility facilitates the production of more aerodynamic vehicles, thereby improving fuel efficiency. Lastly, aluminum sheets possess a high strength-to-weight ratio, meaning they provide the necessary strength while remaining lightweight. This property makes aluminum an ideal material for applications that require strength and durability, such as vehicle bodies, chassis, and structural components. In conclusion, the utilization of aluminum sheets in the transportation industry provides advantages such as weight reduction, corrosion resistance, sustainability, formability, versatility, and a high strength-to-weight ratio. These benefits contribute to improved performance, fuel efficiency, and durability of vehicles, making aluminum an excellent choice for various transportation applications.

- Q: I use an aluminum chloride deodorant at night for hyperidrosis...I'm scared I may get senile dementia when i get older!!!!! can anyone give advice??? pls..i've been using it for 3yrs

- Aluminium has been established as a neurotoxin.[1] Aluminium chloride, an aluminum salt that is commonly used in antiperspirants, is also commonly used in studies on aluminium-induced neurotoxicity[2][3][4][5][6]. Aluminium itself adversely affects the blood-brain barrier, is capable of causing DNA damage, and has adverse epigenetic effects.[7][8] Research has shown that the aluminium salts used in antiperspirants have detrimental effects to a number of species such as non-human primates[9], mice[10], dogs[11] and others. An increased amount of Aluminium is also present in the brains of many Alzheimer's patients, although it is not yet known if this link is causal.[12][13] I found this for you I hope it helps. Alzhaimer is also genetic. As it says here there is a link. Among that there could be other links to this disease. The best way is to keep your mind active. Active meaning reading even as you get older. I have witness patients come in to a home facility alert and then they give up. They stop reading, interacting and using their mind. Do further research and talk to your doctor.

- Q: What are the different types of surface treatments available for painted aluminum sheets?

- There are several different types of surface treatments available for painted aluminum sheets. These treatments are designed to enhance the appearance and durability of the aluminum, as well as provide protection against corrosion and other forms of damage. One common type of surface treatment is anodizing. Anodizing involves immersing the aluminum sheets in an electrolytic solution and passing an electric current through them. This process creates a protective oxide layer on the surface of the aluminum, which not only improves its corrosion resistance but also provides a base for painting or other decorative finishes. Another popular surface treatment for painted aluminum sheets is powder coating. Powder coating involves applying a dry powder to the surface of the aluminum and then heating it to form a tough, protective layer. This coating is known for its durability, resistance to fading and chipping, and ability to provide a wide range of colors and finishes. In addition to anodizing and powder coating, there are also other surface treatments available for painted aluminum sheets. These include chemical conversion coating, which involves applying a chemical solution to the aluminum to create a protective layer, and laminate coatings, which involve applying a thin film or laminate to the surface for added protection and decoration. Overall, the different types of surface treatments available for painted aluminum sheets offer a variety of benefits, including enhanced appearance, improved durability, and increased resistance to corrosion. The choice of surface treatment will depend on the specific requirements and desired outcomes for the aluminum sheets in question.

- Q: What are the advantages of utilizing aluminum sheets in construction projects in terms of environmental impact?

- <p>Using aluminum sheets in construction offers several environmental benefits. They are highly recyclable, which reduces waste and conserves natural resources. Aluminum is lightweight, reducing the carbon footprint associated with transportation. It also has a high strength-to-weight ratio, leading to less material usage and lower energy consumption in production. Additionally, aluminum's reflective properties can help in reducing heat absorption, contributing to energy efficiency in buildings. Moreover, aluminum production technology has advanced to minimize harmful emissions, making it a more sustainable choice for construction materials.</p>

- Q: Which kind of glue can bond hard shell plastic and iron sheet or aluminum sheet?

- You can buy the glue for bonding wood in hardware shop, 402 or 502 are all ok.

- Q: This question asks for a list of various types of aluminum sheets that can be found in the market.

- <p>Aluminum sheets available on the market can be categorized based on their thickness, surface finish, and alloy composition. Some common types include: 1) Mill Finish Sheets, which have a natural aluminum finish; 2) Polished Aluminum Sheets, offering a shiny surface; 3) Anodized Aluminum Sheets, which are coated with a protective oxide layer; 4) Checkered Aluminum Sheets, with a slip-resistant pattern; 5) Painted or Coated Aluminum Sheets, with a variety of colors and finishes; 6) Embossed Aluminum Sheets, featuring decorative patterns; 7) Aluminum Foil, which is very thin; and 8) Aluminum Alloy Sheets, such as 6061, 6063, and 2024, each with specific properties for different applications. These types cater to various industries and applications, from construction to automotive and aerospace.</p>

- Q: Alumina is the protective coating that covers aluminum when exposed to oxygen. It's actually corroded aluminum that prevents the aluminum from continuously corroding.What I didn't know until recently was that alumina is an electrical insulator. If that's the case why then isn't aluminum an insulator if one is trying to pass current along its surface?

- Aluminum is an efficient conductor of electricity. A usual fabric that is not conductive is glass but glass will habits heat. Wood isn't warmth conductive or an electricity conductor however has a low combustion factor. You probably have a specific utility you are watching for then you definitely'd better ask extra certain questions.

- Q: Are aluminum sheets suitable for artistic sculptures?

- Yes, aluminum sheets are suitable for artistic sculptures. Aluminum is a versatile material that offers several advantages for sculpting purposes. Firstly, it is lightweight, making it easier to handle and manipulate. This allows artists to create intricate and detailed sculptures without compromising on structural integrity. Additionally, aluminum is highly malleable, meaning it can be shaped into various forms and contours. This allows artists to experiment with different designs and achieve the desired artistic expression. Furthermore, aluminum is resistant to corrosion and weathering, making it ideal for outdoor sculptures. Its durability ensures that the artwork will withstand the elements and retain its aesthetic appeal over time. Additionally, aluminum sheets can be easily welded or joined together, enabling artists to create larger and more complex sculptures. Overall, aluminum sheets provide artists with a flexible and durable material that allows for creativity and longevity in their sculptural works.

Send your message to us

Sublimation Aluminum Sheets Quotes - Aluminum Sheet 1050,1100,5005,5754,8079 for Decorative Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords