Aluminum Profiles South Africa for Specifications of Auto-Parts Applications

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Profile for Specifications of Auto-parts Applications Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Profile for Specifications of Auto-parts Applications:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

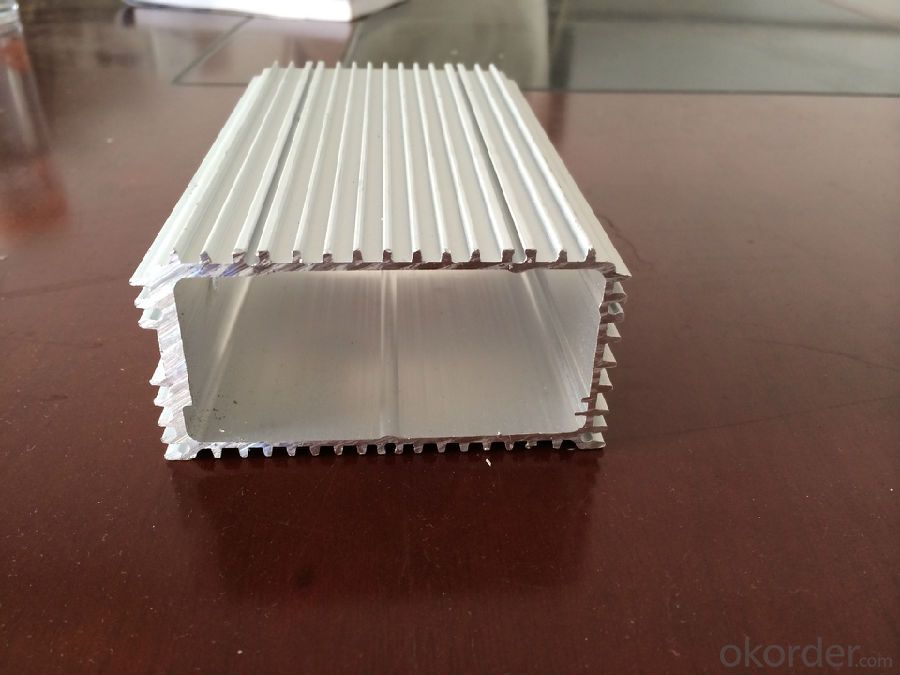

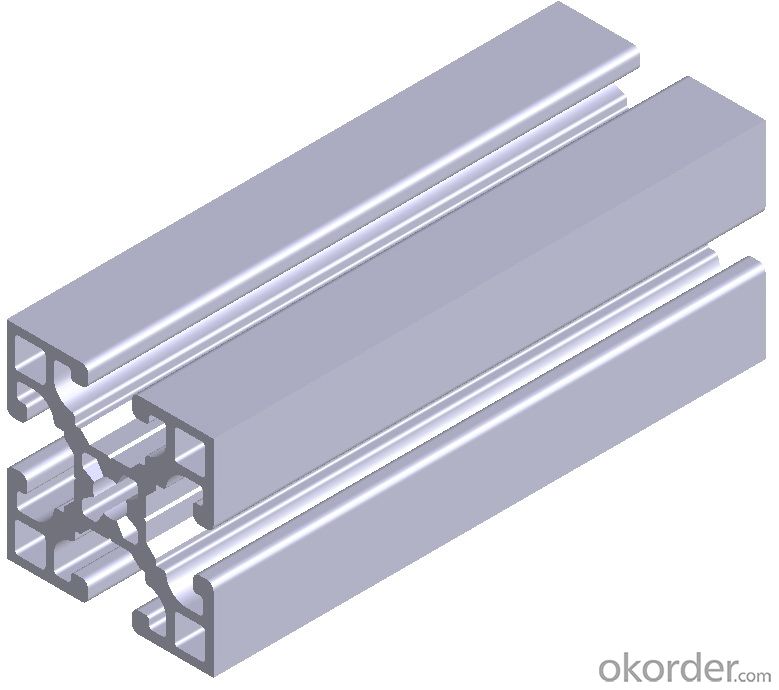

Images of the Aluminium Profile for Specifications of Auto-parts Applications:

Aluminium Profile for Specifications of Auto-parts Applications Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium Cast Slab not Alloyed in Coil Form:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Can aluminum profiles be used for modular office partitions?

- Yes, aluminum profiles can be used for modular office partitions. Aluminum profiles are lightweight, durable, and have high strength-to-weight ratio, making them an ideal choice for creating modular office partitions. They can be easily fabricated into various shapes and sizes, allowing for customization and flexibility in design. Additionally, aluminum profiles offer excellent corrosion resistance, ensuring long-lasting performance even in high humidity environments. They also provide good thermal and sound insulation properties, contributing to a comfortable and efficient office environment. Overall, aluminum profiles are a popular choice for modular office partitions due to their versatility, durability, and aesthetic appeal.

- Q: What are the different surface texturing options for aluminum profiles?

- Aluminum profiles have a variety of surface texturing options to choose from, each with its own unique benefits and aesthetic appeal. Some of the common options include: 1. Brushing or Satin Finishing: By using abrasive brushes, a linear or circular pattern can be created on the surface of the aluminum profile. This technique provides a visually appealing smooth and matte finish, effectively hiding minor imperfections. 2. Anodizing: Anodizing is a widely used method that involves creating an oxide layer on the aluminum surface. This not only enhances the profile's corrosion resistance but also allows for the application of different colors, making it an excellent choice for decorative purposes. 3. Polishing: The process of mechanically smoothing the surface of the aluminum profile achieves a reflective finish. Polishing is commonly used in architectural applications where a high-gloss appearance is desired. 4. Powder Coating: Powder coating is a versatile and durable surface treatment option. It involves electrostatically applying a dry powder to the profile, followed by curing under heat. This creates a protective and decorative coating that offers a wide range of color options and excellent resistance to weathering, suitable for both interior and exterior applications. 5. Textured Coating: This specialized powder coating technique provides a unique texture and appearance to the aluminum profile. It can mimic textures like wood grain or stone, adding a distinctive look to the profile. 6. Chemical Etching: By selectively removing material from the surface using chemical solutions, intricate patterns or designs can be created. Chemical etching is ideal for decorative or branding purposes. 7. Laser Engraving: Laser engraving is a precise and versatile method for creating patterns, logos, or text on the surface of aluminum profiles. The laser beam removes material, leaving a permanent mark. This technique offers high precision and customization options, making it suitable for branding and personalization. These examples showcase the range of surface texturing options available for aluminum profiles. The choice of method depends on the desired appearance, functionality, and application of the profile.

- Q: Is there any health risk linked to the use of aluminum profiles in construction?

- <p>There are minimal health risks associated with using aluminum profiles in construction. Aluminum is a non-toxic metal and does not emit harmful substances. However, during the manufacturing process, if not properly controlled, there might be exposure to dust or fumes which could be harmful if inhaled. Additionally, aluminum dust can cause skin irritation. It's important to handle aluminum profiles with care and use appropriate safety measures, such as wearing masks and gloves, to minimize any potential health risks.</p>

- Q: Shenzhen aluminum profile manufacturers which good?

- Explain as follows: preparing goods, recruit a few operator, big online promotion can be opened. Those who are often hurt are our buyers. Miss wiring mostly do not know how to use, only know the unit price. How to use to meet customer needs; how to make the most cost-effective; in different venues that kind of connection is the best; these are they can not answer accurately. Only know the cheapest and recommended profile connection the cheapest; this connection is the lowest cost, but the cost of artificial, a connection is the weakest, aluminum convenience wouldn't be reflected, and will bring much trouble for the future reconstruction. But the wiring girl will push it one way.Third: in production of aluminium supplierExplain as follows: in the production of aluminum suppliers, are generally engaged in this industry for more than 10 years, and their users have very rich experience, have a good understanding and knowledge of the quality and performance of products, suitable for the requirement of the customers will recommend price is a good product, choose a convenient and practical accessories.

- Q: Can aluminum profiles be used in corrosive environments?

- Aluminum profiles can be used in corrosive environments, but it is important to consider certain factors before making a decision. Aluminum is naturally resistant to corrosion due to the formation of a protective oxide layer on its surface. This layer acts as a barrier, preventing further corrosion. However, in highly corrosive environments such as areas with high humidity, saltwater exposure, or acidic conditions, the protective oxide layer may deteriorate over time. To enhance the resistance of aluminum profiles in corrosive environments, various measures can be taken. One option is to choose an aluminum alloy with higher corrosion resistance, such as aluminum alloys with a higher percentage of alloying elements like copper or zinc. These alloys are often referred to as marine-grade or corrosion-resistant alloys. Additionally, surface treatments like anodizing or powder coating can further improve the corrosion resistance of aluminum profiles. Anodizing involves the formation of a thicker and more durable oxide layer on the surface of the aluminum, while powder coating provides an additional protective layer that acts as a barrier against corrosive agents. Regular maintenance and cleaning are also crucial for preserving the corrosion resistance of aluminum profiles in corrosive environments. This includes removing any accumulated dirt or debris that may contain corrosive substances. In summary, while aluminum profiles can be used in corrosive environments, it is essential to select the appropriate alloy, consider surface treatments, and perform regular maintenance to ensure their long-term performance and durability.

- Q: How do aluminum profiles perform in terms of impact resistance?

- Known for their excellent impact resistance, aluminum profiles are able to withstand significant impact without becoming easily deformed or damaged, thanks to their inherent strength and durability. The ideal strength-to-weight ratio of aluminum makes it particularly suitable for industries such as automotive, aerospace, and construction, where impact resistance is crucial. In addition, the structure of aluminum profiles allows them to absorb and distribute impact energy, thereby preventing localized damage. This property proves especially advantageous in situations that require resistance to sudden shocks, collisions, or heavy loads. Moreover, aluminum profiles can be customized with specific reinforcements or structural elements to further enhance their impact resistance. This flexibility allows for meeting specific requirements or addressing areas prone to impact. In summary, the exceptional impact resistance of aluminum profiles makes them highly valued in industries and applications where strength and durability are essential.

- Q: This question is asking about the various types of insulation materials that can be used with aluminum profiles, which are commonly found in construction and manufacturing for their strength and light weight.

- <p>There are several types of insulation available for aluminum profiles, including thermal insulation, acoustic insulation, and electrical insulation. Thermal insulation materials such as polyurethane foam or mineral wool can be used to prevent heat transfer. Acoustic insulation, like soundproofing panels or rubber seals, can reduce noise transmission. Electrical insulation is crucial for preventing electrical conductivity and can be achieved with materials like neoprene or silicone rubber. Each type serves a specific purpose and is chosen based on the application's requirements, such as temperature control, noise reduction, or electrical safety.</p>

- Q: What does aluminum T1.5 mean?

- Aluminum should be referred to the thickness of 1.5MM thick.

- Q: Can aluminum profiles be used in the construction of greenhouses?

- Yes, aluminum profiles can be used in the construction of greenhouses. Aluminum is a lightweight and durable material, making it an excellent choice for greenhouse construction. It is resistant to corrosion, which is important in a moist and humid environment like a greenhouse. Aluminum profiles can be easily fabricated and assembled, allowing for flexibility in design and construction. Additionally, aluminum is a sustainable material as it is 100% recyclable, making it environmentally friendly for greenhouse construction. Overall, aluminum profiles are a practical and reliable option for building greenhouses.

- Q: This question asks about the various methods employed in the production of aluminum profiles, which are long, extruded shapes made from aluminum.

- <p>Aluminum profiles are manufactured using several processes, primarily extrusion, which involves forcing aluminum through a die to create specific shapes. Other processes include casting, where aluminum is poured into molds, and rolling, used to create flat sheets or plates. Machining processes like cutting, drilling, and milling are also used for further shaping and finishing. Additionally, aluminum profiles can be fabricated through bending, which shapes the material into curves or angles, and welding, which joins pieces together. Surface treatments like anodizing, painting, or powder coating are also applied to enhance appearance and durability.</p>

Send your message to us

Aluminum Profiles South Africa for Specifications of Auto-Parts Applications

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords