Aluminum Profiles and Accessories for Solar Panel Frame Making

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Aluminium Profiles for making Solar Panel Frame Description

Aluminium Profiles for making Solar Panel Frame is one semi-finished aluminium material. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Aluminium Profiles for making Solar Panel Frame

Aluminium Profiles for making Solar Panel Frame | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Aluminium Profiles for making Solar Panel Frame

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Aluminium Profiles for making Solar Panel Frame

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Aluminium Profiles for making Solar Panel Frame

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

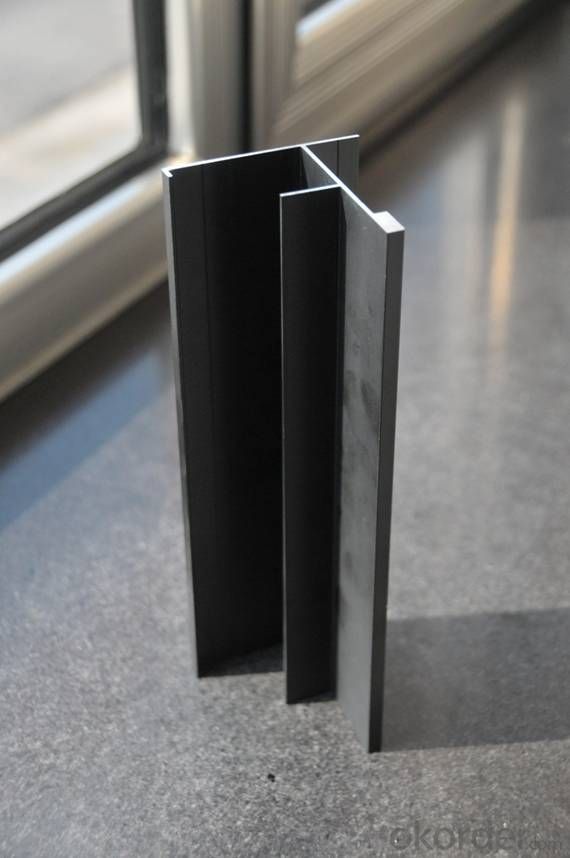

6. Image of Aluminium Profiles for making Solar Panel Frame

7. Package and shipping of Aluminium Profiles for making Solar Panel Frame

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the standard dimensions of aluminum profiles?

- The standard dimensions of aluminum profiles can vary depending on the specific application and industry. However, some common standard dimensions include widths ranging from 10mm to 200mm and heights ranging from 10mm to 100mm. The length of aluminum profiles can also vary, with standard lengths typically ranging from 2 meters to 6 meters. It is important to note that these dimensions can be customized to meet specific project requirements.

- Q: Is it possible to recycle aluminum profiles and what are the benefits of doing so?

- <p>Yes, aluminum profiles can be recycled. Recycling aluminum is energy-efficient, as it requires only 5% of the energy needed to produce new aluminum from raw materials. This process reduces greenhouse gas emissions and conserves natural resources. Recycled aluminum maintains its quality, making it suitable for various applications, including construction, automotive, and consumer goods. Proper recycling also helps to reduce landfill waste and promotes a circular economy.</p>

- Q: 6063 aluminum manufacturers fail to notice how to write a written report

- Ask if your manufacturer has a template. How do you write it?In fact, this is not what the provisions of how to write, as long as the two agreed to make things clear, double admit something on the line, cover double seal, all right, hope to be able to help you, thank you for the adoption.

- Q: Aluminum 3100-6063-T5, please

- Aluminum in the industry according to material characteristics, such as hardness, strength, corrosion resistance and other categories, there are 8 main series, each series with 4 figures as a brand, and subdivided into many types1 series industrial pure aluminum: 1XXX2 series superhard aluminum material: 2XXX3 series easy cutting aluminum material: 3XXX4 series easy cutting aluminum material: 4XXX5 series magnesium aluminum alloy: 5XXX6 series anodic oxidation and corrosion resistant aluminum: 6XXX7 Series aviation ultra hard aluminum: 7XXX8 series: 8XXXYou say 3100-6063-T5 may contain the 3 and 6 series, easy to cut and resistant to corrosion,.T5 indicates hardness levels

- Q: Can aluminum profiles be used for safety barriers or guardrails?

- Yes, aluminum profiles can be used for safety barriers or guardrails. Aluminum is a lightweight yet strong material that offers good durability and resistance to corrosion. It can be easily fabricated into various shapes and sizes, making it suitable for constructing safety barriers or guardrails in different settings such as roads, construction sites, or industrial facilities. Additionally, aluminum profiles can be easily installed and maintained, making them a practical choice for safety applications.

- Q: What are aluminum profiles used for?

- Aluminum profiles are commonly used in construction, manufacturing, and industrial applications. They are used for framing structures, such as doors, windows, and curtain walls, providing strength and durability while maintaining a lightweight design. Additionally, aluminum profiles are used in the production of machinery, electrical enclosures, automotive parts, and various consumer products, due to their corrosion resistance, heat conductivity, and versatility in shaping.

- Q: Are aluminum profiles suitable for use in aerospace structural components?

- Indeed, aerospace structural components can indeed benefit from the utilization of aluminum profiles. Aluminum, given its lightweight and robust nature, proves to be an optimal selection for aerospace applications that prioritize weight reduction. Moreover, it boasts a commendable strength-to-weight ratio, exceptional resistance to corrosion, and remarkable malleability, thereby enabling the construction of intricate shapes and structures. Furthermore, the versatility of aluminum profiles is evident in their effortless integration through diverse methods such as welding, riveting, or adhesive bonding, thereby enabling their adaptability in the assembly of aerospace structural components. In summary, the amalgamation of its exceptional properties and ease of manufacturing renders aluminum profiles an apt choice for aerospace structural components.

- Q: Are aluminum profiles weather-resistant?

- Indeed, aluminum profiles exhibit a commendable resistance to weather conditions in general. Renowned for its ability to resist corrosion and endure diverse climatic circumstances, aluminum distinguishes itself from iron or steel by not succumbing to rust. Consequently, it emerges as an exceptional material for outdoor purposes. Furthermore, aluminum profiles can undergo treatments with diverse coatings or finishes to bolster their resilience against inclement weather. These coatings offer supplementary safeguarding against detrimental UV rays, moisture, and other environmental elements. All in all, aluminum profiles prove themselves as robust and trustworthy selections for outdoor utilization, rendering them well-suited for an extensive array of industries and applications.

- Q: What are the weight capacities of aluminum profiles for shelving systems?

- The weight capacities of aluminum profiles for shelving systems can differ based on a variety of factors, including the profiles' dimensions, the shelving system's design, and the quality of the aluminum used. In general, aluminum profiles used for shelving systems can handle a substantial amount of weight. Nevertheless, it is important to acknowledge that the weight capacity of a shelving system also relies on other components like brackets, connectors, and the type of shelving material (e.g., wood, glass, or metal shelves) used. To obtain accurate weight capacity information, it is advisable to consult the manufacturer or supplier of the specific aluminum profile and shelving system. They can offer guidelines derived from their product specifications, engineering calculations, and testing. Additionally, proper installation, weight distribution, and regular maintenance are also vital factors in ensuring the overall strength and stability of a shelving system.

- Q: What materials are used for aluminum profile packing?

- if the surface requirements is not high, three point type packaging is also common, some products need to add pearl carton / wooden packaging. Shanghai aluminum products Co., Ltd.

Send your message to us

Aluminum Profiles and Accessories for Solar Panel Frame Making

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords