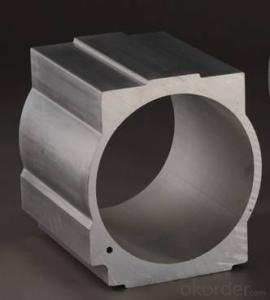

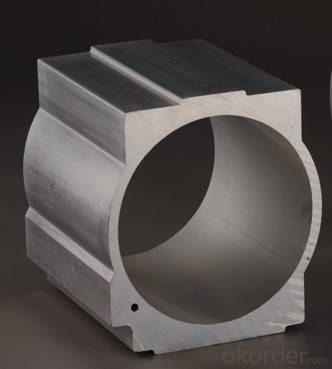

Aluminum Pipe Air Cylinder Shell

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are the largest aluminum profilemanufacture in

Material | Alloy Aluminum 6063,6061,6005,6082 or customer nominated |

Temper | T3, T4, T5, T6 and other |

Surface | Anodize, Mill,rtc |

Colour | Mill |

Length | -- |

Good Package | Inner plastic film /outside carton/wooden pallets |

Payment Method | T/T, L/C, etc |

Delivery Time | Normally 2-4 weeks, Delivery time can be consulted. |

Press Machine | 500-12500 tons all together 93 press lines. |

Fabrication | 1. Air cylinder shell; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO/TS 16949,DNV,IRIS,CCS,AFA,etc. |

Dies | 1. Using our dies, no fee; |

2. Using customer drawing, opening dies, usually about 5~50 tons then the dies cost can be refunded. | |

3. Die cost is negotiable base on the order quantity | |

Capability | Annual output 800,000 tons |

- Q: What's the difference between 6061 tubes and 6063?

- If a certain amount of manganese and chromium, can neutralize the bad effect of iron; sometimes add a small amount of copper or zinc, to improve the strength of the alloy, and the corrosion resistance decreased significantly; there is a small amount of copper conductive materials, titanium and iron in order to offset the adverse effects on the conductivity of the zirconium; or titanium recrystallization grain refinement and control;

- Q: How to repair the surface defects of aluminum pipe

- Method: to hand percussion pits with oxyacetylene flame annealing, after cooling, use hand hammer into the aluminum oblate tube, estimated knocking position try to knock, knock point and observe from the outside, adjusted and confirmed the knock point after the afterburner struck, until the elimination of pits. If it is difficult to strike in the middle, it is expected to be hardened by metal hammering. It must be reheated and annealed again, and then continue after cooling. The method is generally applicable to the repair of the larger diameter aluminum tube and the hand length of the pit. Not suitable for trimming of flattening defects

- Q: What are the different cutting methods for aluminum pipes?

- There are multiple cutting techniques available for aluminum pipes, depending on the desired level of accuracy and efficiency. 1. Manual Hacksaw: This basic method entails using a manual hacksaw to cut through the aluminum pipe. It is suitable for smaller projects and provides decent precision, but it can be time-consuming and physically demanding. 2. Power Hacksaw: This method involves utilizing a power hacksaw, which is an electrically powered version of the manual hacksaw. It offers faster and smoother cuts, making it suitable for larger pipes or more extensive projects. 3. Circular Saw: Another option is to employ a circular saw equipped with a metal-cutting blade. This method offers a quicker cutting process than hacksaws and is ideal for thicker aluminum pipes. However, it may generate more heat and produce rougher edges. 4. Band Saw: A versatile cutting tool, the band saw is well-suited for cutting aluminum pipes. It provides precise cuts and allows for various cutting angles. Band saws are frequently used in industrial settings due to their efficiency and accuracy. 5. Pipe Cutter: A specialized pipe cutter is another effective method for cutting aluminum pipes. This tool is specifically designed for pipes and delivers clean and precise cuts. It is easy to use and suitable for both small and large pipes. 6. Plasma Cutter: For intricate cuts or irregular shapes, a plasma cutter is an excellent option. It employs a high-velocity jet of ionized gas to melt and cut through the aluminum pipe. This method offers precision and speed and is commonly used in industries that require such cuts. 7. Waterjet Cutting: Waterjet cutting involves the use of a high-pressure jet of water combined with abrasive materials to cut through aluminum pipes. It is a precise and versatile method that can handle various thicknesses and shapes. This technique is often used for complex or custom designs. Each cutting method has its own advantages and disadvantages. The choice depends on factors such as the project type, desired precision, efficiency, and available tools. It is crucial to consider safety precautions and use appropriate protective gear when working with any cutting method for aluminum pipes.

- Q: How can the aluminum pipe burr be convenient?Burr left by drilling

- The internal tube is burr! Not very long words can be a round drill clamp in the round head through a 1 mm wide and about 30 mm in the hole, and then put the paper cut up into 30 broad band card in the slot to rotate in the opposite direction wrapped up! Until Guan Zikong was slightly more than a little good! So you can clear burrs on the inner wall of the!

- Q: How can the refrigerator be welded with copper aluminum tube?

- Welding powder, copper electrode can be used welding!

- Q: Can the air conditioner low pressure pipe and high pressure pipe be expanded with aluminium pipe at the two ends?

- Yes, but the aluminum tube is easy to crack. Be very careful. I opened a shop maintenance for seven or eight years, only a few times with aluminum pipe to do the bell mouth, the problem is not, just be careful. Of course, it is recommended to use brass bell mouth, good toughness, not easy to crack.

- Q: Can aluminum pipes be used for swimming pool systems?

- Yes, aluminum pipes can be used for swimming pool systems. Aluminum is a popular choice for pool systems due to its durability, resistance to corrosion, and lightweight nature. It is commonly used for piping, especially in areas with high moisture or corrosive conditions, making it a suitable option for swimming pool systems.

- Q: The aluminum extrusion seam? Is there a big difference between the two?

- Seamless aluminum tube production process: reverse through the core (hole) to form seamless pipeThe production process of aluminum tube seam: conventional tubes is generally used for combination die extrusion, which is produced by extrusion, is welded, the welding seam is automatically in high temperature.

- Q: Which is faster, the aluminum tube and the copper tube radiator on the computer?

- If it is household, of course, copper aluminum tube is good.You said radiator, use the occasion to be more specific.

- Q: What is the difference between the 6061-T6 aluminum pipe and the common aluminum pipe?

- Alcoa 6061-T651 has excellent processing properties, corrosion resistance, high toughness and processing after deformation, color film is easy, excellent oxidation effect and excellent characteristics of good.Al-Mg-Si series alloy, medium strength, with good plasticity and excellent corrosion resistance. Especially the tendency of non stress corrosion cracking, which has good weldability, good corrosion resistance and cold workability, is a widely used and promising alloy. It can be anodized, painted, or painted with enamel. It is suitable for building decoration materials. It contains a small amount of Cu, so the strength is higher than 6063, but the sensitivity of quenching is higher than that of 6063. After extrusion, the air can not be quenched, and it needs to be solved again by solid solution treatment and quenching aging so as to obtain higher strength.

Send your message to us

Aluminum Pipe Air Cylinder Shell

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords