Aluminum Mill Coil PVDF Coated Mill Finished Aluminium Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Mill Finished PVDF Coated Aluminium Composite Panel Description

Mill Finished PVDF Coated Aluminium Composite Panel is one semi-finished aluminium material. It can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Mill Finished PVDF Coated Aluminium Composite Panel

Mill Finished PVDF Coated Aluminium Composite Panel | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Mill Finished PVDF Coated Aluminium Composite Panel

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Mill Finished PVDF Coated Aluminium Composite Panel

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Mill Finished PVDF Coated Aluminium Composite Panel

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

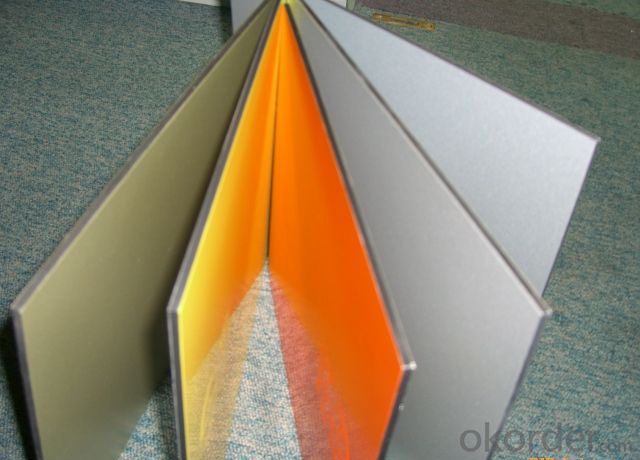

6. Image of Mill Finished PVDF Coated Aluminium Composite Panel

7. Package and shipping of Mill Finished PVDF Coated Aluminium Composite Panel

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the different thickness options for aluminum coils?

- The thickness options for aluminum coils can vary, but common thicknesses range from 0.019 inches to 0.125 inches.

- Q: Are there any specific maintenance requirements for aluminum coils?

- Yes, aluminum coils require regular maintenance to ensure optimal performance and longevity. Some specific maintenance requirements for aluminum coils include cleaning them regularly with a mild detergent and water solution, removing any debris or dirt that may accumulate on the coils, inspecting for any signs of corrosion or damage, and ensuring proper airflow around the coils by keeping the surrounding area clear. Additionally, it is important to schedule professional maintenance and tune-ups to check for refrigerant leaks or any other issues that may affect the performance of the aluminum coils.

- Q: How does aluminum ingot be processed to aluminum coil (aluminum sheet)?

- First it should be made into blank and then put on the rolling mill.

- Q: Is it possible to join steel coils using arc welding or gas welding techniques?

- <p>Yes, steel coils can be welded together using both arc welding and gas welding methods. Arc welding, specifically processes like Shielded Metal Arc Welding (SMAW) and Gas Metal Arc Welding (GMAW), is commonly used for joining steel due to its strength and versatility. Gas welding, which uses a fuel gas and an oxygen mixture to produce a flame, is also suitable for steel welding, although it may be less common in industrial settings due to the higher heat input and potential for distortion. Proper techniques and equipment are essential to ensure a strong, durable weld and to avoid defects such as cracking or warping.</p>

- Q: What are the common surface finishes for aluminum coils in the automotive industry?

- The common surface finishes for aluminum coils in the automotive industry include mill finish, painted finish, anodized finish, and laminated finish.

- Q: Can aluminum coils be used for HVAC condenser coils?

- Yes, aluminum coils can be used for HVAC condenser coils. Aluminum is a popular choice for condenser coils due to its excellent heat transfer properties, durability, and resistance to corrosion. Additionally, aluminum coils are lightweight, making them easier to install and transport.

- Q: Some manufactures (Kia, Hundai) use Iron blockswhileOther manufactures (Nissan, Chevy, ect.) use Aluminum blocks*****Is the point of using Iron blocks to increase long-term durability or temperature endurance??ORIs the use of Iron blocks simply an older, simpler technology (as compared to using Aluminum), the manufacture of which costs less money??And you would think that Aluminum weight savings would transer to better MPG, but the Kia gets very comparable mileage anyway.Thank you

- Aluminum's main advantages are weight and increased mpg for CAFE regulations. If you are going to keep your car to 150,000 miles eitheir block material will do. But if you are going to keep it 300,000 to the bitter, bitter end, you are better off with iron.

- Q: Can aluminum coils be used for solar panel installations?

- Indeed, solar panel installations can utilize aluminum coils. Aluminum, renowned for its lightweight nature, durability, and corrosion resistance, is frequently employed within the solar industry. As framing materials for solar panel mounting, aluminum coils furnish a robust and enduring support structure. Moreover, they boast exceptional heat dissipation properties, crucial for optimizing solar panel efficiency. Notably, aluminum coils are also user-friendly, rendering the installation process more convenient. All in all, opting for aluminum coils in solar panel installations proves to be a widely favored and efficient decision.

- Q: Are aluminum coils suitable for automotive body panels?

- Indeed, automotive body panels can be effectively constructed using aluminum coils. The lightweight nature of aluminum greatly contributes to enhancing fuel efficiency and overall vehicle performance. Furthermore, the exceptional corrosion resistance of aluminum makes it an optimal selection for automotive applications, particularly when the panels are frequently subjected to diverse weather conditions. The impressive strength-to-weight ratio of aluminum further ensures outstanding durability and crash resistance. Moreover, aluminum allows for effortless formation and shaping, enabling the creation of intricate and fashionable designs. In conclusion, the utilization of aluminum coils for automotive body panels presents a multitude of benefits, making it a highly favored option for car manufacturers.

- Q: Can aluminum coils be used for signage and display applications?

- Yes, aluminum coils can be used for signage and display applications. Aluminum is a versatile and lightweight material that is widely used in the signage industry. Aluminum coils can be easily formed into various shapes and sizes, making them suitable for a variety of signage and display applications. Aluminum coils are commonly used for outdoor signs, such as billboards, building signs, and traffic signs, due to their excellent weather resistance and durability. They can withstand harsh weather conditions, including rain, snow, and UV exposure, without rusting or fading. This makes them a reliable choice for long-lasting signage. Additionally, aluminum coils can be coated with a variety of finishes, such as paint or powder coating, to enhance their appearance and provide additional protection against corrosion. This allows for customization and branding options, making aluminum coils suitable for both functional and decorative signage. In terms of display applications, aluminum coils can be used to create exhibition stands, trade show displays, retail displays, and various other promotional materials. Their lightweight nature makes them easy to transport, assemble, and disassemble, which is beneficial for portable displays. Furthermore, aluminum coils can be easily printed on or laminated, allowing for the incorporation of graphics and visuals to attract attention and convey messages effectively. Overall, aluminum coils are a versatile and durable material that can be used for a wide range of signage and display applications. Their weather resistance, customizable finishes, and lightweight properties make them a popular choice in the industry.

Send your message to us

Aluminum Mill Coil PVDF Coated Mill Finished Aluminium Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords