Galvanized Aluminum Sheets - Aluminum Household Foil AA8011 0.009-0.030mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Grade:

7000 Series,6000 Series,5000 Series,4000 Series,3000 Series,2000 Series,1000 Series

Surface Treatment:

Color Coated,Oxidized,Polished,Anodized,Embossed,Coated,Printed,Brushed,Enameled Wire,Mill Finish,Powder Coating,Sand Blasted,Holographic Impression,Composited

Shape:

Hexagonal,Oval,Rectangular,Flat,Round,Square,Angle,T-Profile

Temper:

Half Hard,Hard,Soft,T351-T851,T351-T651,O-H112,T3-T8

Application:

Decorations,Door & Window,Heat Sink,Transportation Tools,Glass Wall,Food,Kitchen Use,Pharmaceutical,Seal & Closure,Insulation Material,Label & Tag,Liner & Wad

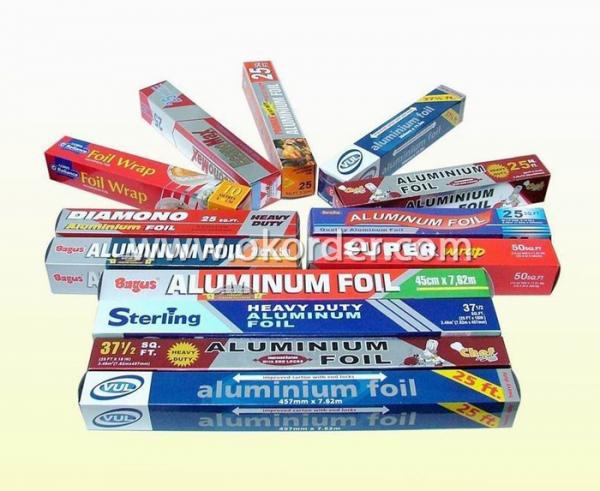

1 Quick details of Aluminum Foil For Household

| Original Price | USD2330 |

| Current Price | USD2290 |

| Alloy | AA8011 |

| Temper: | O |

| Thickness: | 9μ |

| Width&Tolerance: | 200mm-1650mm(±1mm) |

| Standard: | GB/T17748-1999, ASTM, ISO, EU standard |

| Special Specification is available on customer’s requirement | |

2 Usage/Application of Aluminum Foil For Household

Used for food wrapping, household package

| NO | Denomination | Final application | Temper | Thickness | Width | Inner diameter | Outside |

| diameter | |||||||

| 1 | Semi-rigid container foil | Food container applied in aviation | 3003/8011--H22,H24,O | 0.02-0.09 | 300-600 | 76/152 | 100-600 |

| 2 | Household foils | Soft packing in household | 8011--O | 0.01-0.02 | 200-700 | 76 | 200-800 |

| 3 | Pharmaceutical foil | Packing for Blister foil | 8011--H18 | 0.020-0.025 | 400-1100 | 76/152 | 760 |

| 4 | Cable foil | Wraping for cable | 1100/8011,O | 0.15-0.05 | 500-800 | 76 | 760 |

| 5 | Aluminum fin stock | Hear exchanger and condensator for A/C | 8011--H24,O | 0.1-0.13 | 400-1000 | 152 | 760 |

| 6 | Cigarette foil | Packing for cigarette | 1235--O | 0.0065-0.007 | 460,520 | 76 | 400 |

| 7 | Foil for hot seal | Hot seal cover for acidophilus milk and other beverage | 1235/8011--O | 0.02-0.038 | 400-600 | 76 | 760 |

| 8 | Thick foil for deep processing | Seal for beer bottle | 1145/8011,O | 0.0115 | 300-600 | 76/152 | 400/760 |

| Shield for video cable | 0.01-0.012 | 500 | 76 | 400 | |||

| Aluminum adhesive tape | 0.2-0.06 | 300-600 | 76/152 | 400/760 | |||

| 9 | Thin foil for deep-processing | Foil with thickness less than ten micron applied in surface of packing materials | 8011/1235--O | 0.0065-0.007 | 460-1000 | 76 | 400 |

| 10 | Foil for automobile radiator | Water tank radiator in automobile | 8011/1050--H18 | 0.08-0.10 | 140-600 | 76 | 760 |

3 Packaging & Delivery of Aluminum Foil For Household

Packing: seaworthy wooden box with pallet

Delivery: to be loaded by 1 x 20 feet container

- Q: Can aluminum sheet be used for electrical grounding applications?

- Yes, aluminum sheet can be used for electrical grounding applications. Aluminum is a highly conductive material, making it suitable for use in grounding systems. It is often used in various electrical applications due to its low resistance and excellent electrical conductivity. Aluminum sheet can effectively carry electrical current and safely dissipate it into the ground, ensuring the protection of electrical systems and preventing electrical hazards. Additionally, aluminum's lightweight and corrosion-resistant properties make it a preferred choice for grounding applications in various industries, including construction, automotive, and aerospace.

- Q: Are the aluminum sheets suitable for manufacturing lighting fixtures?

- Yes, aluminum sheets are suitable for manufacturing lighting fixtures. Aluminum is a lightweight and versatile material that offers several advantages for lighting fixture manufacturing. Firstly, aluminum is known for its excellent thermal conductivity, meaning it can effectively dissipate heat generated by the lighting components. This helps in prolonging the lifespan of the lighting fixtures and maintaining their efficiency. Additionally, aluminum is corrosion-resistant, which is crucial for lighting fixtures as they are often exposed to different environmental elements. This property ensures that the fixtures will not degrade over time and can withstand outdoor conditions. Moreover, aluminum sheets can be easily formed into various shapes and sizes, allowing manufacturers to create customized designs for lighting fixtures. This versatility makes aluminum an ideal choice for both functional and aesthetic lighting applications. Furthermore, aluminum is a sustainable and eco-friendly material. It is recyclable, reducing the environmental impact of manufacturing processes. This makes aluminum sheets a popular choice for manufacturers that prioritize sustainability in their operations. Overall, the excellent thermal conductivity, corrosion resistance, versatility, and sustainability of aluminum sheets make them highly suitable for manufacturing lighting fixtures.

- Q: Can aluminum sheets be easily shaped or bent into desired forms?

- Aluminum sheets possess the advantageous characteristic of being effortlessly malleable, allowing them to be shaped or bent into desired configurations. This high malleability of aluminum ensures that it can be easily manipulated without any risk of fracturing or breaking. Moreover, its low density and impressive strength-to-weight ratio deem it an optimal selection for numerous applications that necessitate shaping or bending. Various techniques, including press-braking, roll-forming, or utilization of specialized tools like a sheet metal brake, can be employed to shape or bend aluminum sheets. The simplicity associated with shaping or bending aluminum sheets has propelled its widespread adoption in industries such as automotive, aerospace, construction, and manufacturing, where customized forms and designs are frequently required.

- Q: Is it possible to utilize aluminum sheets for creating signs or banners?

- <p>Yes, you can use aluminum sheets to make signs or banners. Aluminum is a popular choice due to its durability, lightweight, and resistance to weather conditions. It can be easily cut, shaped, and printed on, making it ideal for outdoor signage. Additionally, aluminum sheets can be coated or laminated to enhance their visual appeal and protect against scratches and fading.</p>

- Q: What is the coefficient of expansion for aluminum sheets?

- The coefficient of expansion for aluminum sheets is approximately 0.000022 per degree Celsius. This means that for every degree Celsius increase in temperature, the aluminum sheet will expand by 0.000022 times its original length. This coefficient of expansion is important to consider in applications where the aluminum sheets may be exposed to varying temperatures, as it can affect the overall dimensions and stability of the material.

- Q: What kind of welding rod should be used for aluminum plate, welding and welding?.

- Aluminum plate welding, if it does not take into account the deformation or the objective conditions of the gas, it is recommended to use AC aluminum arc welding machine welding, welding is also commonly used.If considering the deformation and welding method is more simple words, can be used in low temperature aluminum WE53 solid aluminum wire flame welding, the welding is more suitable for super thin aluminum sheet, the thinner the better welding.If it is in the plate, and no argon arc welding machine or manual, you can use the aluminum welding wire welding, aluminum welding wire welding using WEWELDING 555 aluminum electrode welding imports, there is a reference video you can go to see "the use of WE555 aluminum welding wire welding in the Aluminum Alloy"Do not understand, you can continue to ask

- Q: What are the different grades of aluminum sheets available?

- There are several different grades of aluminum sheets available, including 1100, 3003, 5052, and 6061. These grades vary in terms of their composition, strength, and intended use. 1100 aluminum is the most commercially pure grade and is often used for general purpose applications. 3003 aluminum is alloyed with manganese and has improved strength and corrosion resistance. 5052 aluminum is alloyed with magnesium and has excellent weldability and formability. 6061 aluminum is alloyed with magnesium and silicon and is known for its high strength and versatility.

- Q: Can aluminum sheets be used in the aerospace industry?

- Indeed, the aerospace industry does employ aluminum sheets. Aluminum, being a lightweight material with a remarkable strength-to-weight ratio, is highly favored for numerous aerospace purposes. Its usage is prevalent in the manufacturing of aircraft structures, including fuselages, wings, and panels. The adoption of aluminum sheets in the aerospace sector offers several advantages, encompassing diminished fuel consumption due to weight reduction, enhanced maneuverability, and heightened payload capacity. Furthermore, aluminum showcases excellent resistance to corrosion, a vital trait for aircraft operating in harsh environmental conditions. All in all, the aerospace industry extensively relies on aluminum sheets, owing to their advantageous properties and exceptional performance.

- Q: How do aluminum sheets perform in terms of formability?

- Aluminum sheets are highly formable due to their low density and high malleability. They can be easily shaped into various forms and are commonly used in industries such as automotive, aerospace, and construction for their excellent formability properties.

- Q: What are the safety concerns to be aware of when handling aluminum sheets?

- <p>When working with aluminum sheets, there are a few safety concerns to consider. First, aluminum dust can be a respiratory hazard, so it's important to use proper ventilation and personal protective equipment like masks. Second, sharp edges can cause cuts; always handle aluminum sheets with gloves and proper tools. Additionally, aluminum is a good conductor of electricity, so avoid contact with live electrical wires. Lastly, when cutting or shaping aluminum, eye protection is crucial due to the risk of flying debris. Always follow safety guidelines specific to your workplace and the tools you are using.</p>

Send your message to us

Galvanized Aluminum Sheets - Aluminum Household Foil AA8011 0.009-0.030mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords