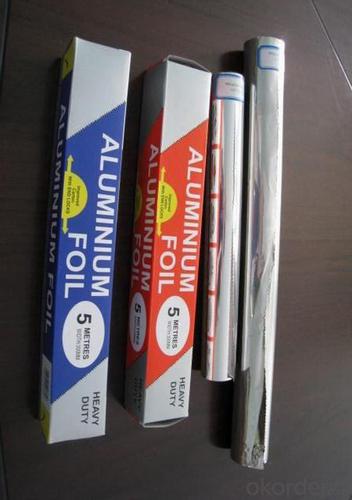

Aluminum Household Aluminium Foil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 7000MT/MONTH m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick details of Aluminium Foil for household

Alloy: 8011/1235

Temper: O

Specifications of Aluminium Foil for household

Thickness & Tolerance: 0.009mm-0.04mm (±6%)

Width & Tolerance: 280mm, 290mm, 300mm, 450mm

Mechancial Properties: Tensile Strength(U.T.S)≥50Mpa, Elongation≥1%

Standard: GB/T3198 / ASTM-B209 / EN546

Usage/Application of Aluminium Foil for household

For Household package

Packaging & Delivery of Aluminium Foil for household

Packing: seaworthy wooden box with pallet

Delivery: to be loaded by 1 x 20 feet container

- Q: Is it possible to utilize aluminum as a component in battery technology?

- <p>Yes, aluminum can be used in batteries. Aluminum-air batteries are a type of metal-air battery that uses aluminum as the anode. These batteries have a high energy density and are lightweight, making them suitable for certain applications. However, they also have challenges such as the need for a specific electrolyte and issues with aluminum corrosion, which limit their practical use compared to more common battery technologies like lithium-ion batteries.</p>

- Q: Is aluminum a suitable material for use in electronic equipment?

- <p>Yes, aluminum is widely used in electronic equipment due to its excellent electrical conductivity, lightweight nature, and high thermal conductivity. It is commonly used in heat sinks, cases, and connectors. However, it is not as conductive as copper, so it is often used in applications where its other properties are more critical. Additionally, aluminum's corrosion resistance makes it a durable choice for various electronic components.</p>

- Q: What is the measure of aluminum's strength, specifically its yield strength and tensile strength?

- <p>Aluminum's strength is typically measured in terms of its yield strength and tensile strength. The yield strength of aluminum varies depending on the alloy and heat treatment, but it generally ranges from 10 to 45 MPa. Tensile strength, which is the maximum stress that aluminum can withstand before breaking, is typically between 90 to 600 MPa for different aluminum alloys. These values make aluminum a lightweight yet strong material suitable for various applications, including construction, automotive, and aerospace industries.</p>

- Q: Explain the interaction between aluminum and oxygen.

- <p>Aluminum and oxygen have a reactive relationship. When aluminum is exposed to oxygen, it forms a thin, protective layer of aluminum oxide on its surface. This oxide layer prevents further oxidation of the aluminum beneath it, making aluminum a corrosion-resistant metal. The reaction is exothermic and can be represented by the chemical equation: 4Al + 3O2 鈫?2Al2O3. This aluminum oxide layer is hard and stable, which is why aluminum is widely used in various applications where resistance to corrosion is important.</p>

- Q: Describe the steps involved in the manufacturing of aluminum sheets.

- <p>The process of manufacturing aluminum sheets involves several key steps. Initially, aluminum ore, typically bauxite, is mined and then processed to remove impurities. The purified aluminum oxide is then dissolved in a cryolite bath at high temperatures, a process known as the Hall-H茅roult process. This results in molten aluminum, which is then cast into ingots. These ingots are reheated and passed through rollers to gradually reduce their thickness, creating aluminum sheets. The sheets are then cooled, cut to size, and may undergo further treatments like annealing or coating, depending on their intended use. The final product is a flat, thin sheet of aluminum ready for various applications.</p>

- Q: This question asks for a list of negative aspects or drawbacks associated with the use of aluminum.

- <p>Aluminum, while widely used, has several disadvantages. It is non-magnetic and non-conductive, which limits its use in certain applications requiring these properties. Aluminum is also relatively soft and can dent or scratch easily, affecting its durability in some contexts. Additionally, its production process is energy-intensive and contributes to environmental pollution. Furthermore, aluminum can have negative health impacts if ingested in large quantities, potentially leading to neurological disorders. Lastly, aluminum's light weight can be a disadvantage in applications where greater strength or weight is required.</p>

- Q: Is it possible to recycle aluminum cans to create new ones?

- <p>Yes, old aluminum cans can be recycled to make new ones. The recycling process for aluminum is highly efficient and environmentally friendly. Aluminum cans are collected, sorted, and then shredded into small pieces. These pieces are melted down in a furnace, and the molten aluminum is poured into molds to create new cans. This process uses only 5% of the energy required to produce aluminum from raw materials, making it a sustainable and cost-effective method of production.</p>

- Q: Is it safe to use pure aluminum for baking or roasting food in a traditional oven or grill?

- <p>While pure aluminum is a common material in cookware, it's not recommended for direct use in baking or roasting food in a traditional oven or grill. Aluminum can react with acidic foods, potentially leaching aluminum into the food. Additionally, aluminum foil can burn and create a hazardous situation. For baking or roasting, it's safer to use materials specifically designed for these purposes, such as parchment paper, silicone baking mats, or oven-safe dishes.</p>

- Q: This question asks about the amount of energy needed to produce aluminum, including the process and factors that influence energy consumption.

- <p>Producing aluminum requires a significant amount of energy, primarily due to the electrolytic process used to extract it from its ore, bauxite. The Hall-H茅roult process, the most common method, consumes about 15,000 to 16,000 kilowatt-hours of electricity per ton of aluminum produced. This high energy demand is largely due to the strong chemical bonds in aluminum oxide, which must be broken to release the aluminum. Energy consumption can vary based on the efficiency of the smelting process, the quality of the bauxite, and the energy source used, with renewable energy potentially reducing the carbon footprint but not necessarily the total energy input.</p>

- Q: This question asks for a comparison of the positive and negative aspects of using aluminum as a material.

- <p>Aluminum has several advantages, including its lightweight nature, making it ideal for transportation and construction. It is also highly recyclable, with the recycling process requiring less energy compared to many other materials. Additionally, aluminum is corrosion-resistant, which extends the lifespan of products. On the downside, aluminum is less strong than some other metals, which can limit its use in certain applications. It also has a high thermal conductivity, which can be a disadvantage in situations where insulation is needed. Moreover, aluminum production is energy-intensive, contributing to environmental concerns.</p>

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 250 Million |

| Main Markets | Mid East; North America |

| Company Certifications | ISO 14001:2004;FDA |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 20-30 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Household Aluminium Foil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 7000MT/MONTH m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords