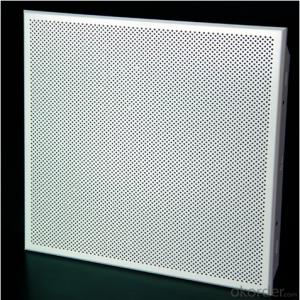

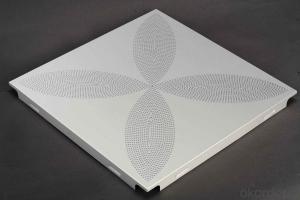

China Colored Anodized Aluminum Grating for Suspended Ceiling Galvanized or Painted

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Drainage trench cover:

Drainage trench cover is widely used in the urban road, the square, the botanical garden, the wharf, the airport, the parking lot, the road, each kind of industry, the civil project, etc.

2.Main features of Drainage trench cover:

I--Carrying 20 tons of weight

II—Carrying 14 tons of weight

III---carrying 6 tons of weight

IV---carrying 2 tons of weight

V---Carrying pedestrian weight

3.Glass Wool Blanket Images:

4. Drainage Trench Cover Technical Parameters:

These drain cover plate applies to the road cross-sectional and longitudinal drain. The drains width ranging from 200mm to 550mm.

A means the steel grating length

H means the steel grating height

A means the frame length

H means the frame height

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Drainage trench cover is

one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Explain how the use of aluminum sheets can impact the energy efficiency of a building.

- <p>Aluminum sheets can significantly affect a building's energy efficiency due to their excellent thermal conductivity and reflective properties. They can be used in building construction to form a barrier against heat transfer, reducing the need for heating and cooling. Additionally, aluminum's reflective surface can help in reflecting sunlight, thereby reducing heat gain in the building. However, if not properly insulated, aluminum's high conductivity can lead to heat loss, reducing energy efficiency. Therefore, the use of aluminum sheets in buildings often requires a balance between their heat-reflective and heat-conductive properties to optimize energy efficiency.</p>

- Q: The user is asking if aluminum sheets can be used as a substitute for metal siding in construction.

- <p>Yes, aluminum sheets can be used to replace metal siding. They are lightweight, durable, and resistant to corrosion, making them a popular choice for siding. Aluminum sheets can be painted or finished to match various architectural styles and are low maintenance. However, it's important to ensure that the aluminum sheets are of the appropriate gauge and quality for the application, and that they are installed correctly to ensure longevity and performance.</p>

- Q: I was looking at Audioque subs earlier and what is the difference between copper and aluminum coiled subs. do aluminum last longer or something?

- the aluminum voice coils will get louder than the copper coils but the sensitivity is lower.ok, say you have one hdc3 copper and hdc3 aluminum.with a 1000 watts rms or smaller amplifier the copper coils will get louder.but if you go with a larger amplifier,say 1500 watts rms or more the aluminum coils will be louder.

- Q: How do I clean and maintain aluminum sheets?

- In order to clean and maintain aluminum sheets, there are several steps that can be followed: 1. To begin, one should prepare a cleaning solution by combining warm water with a mild detergent or dish soap in a bucket or sink. It is important to avoid using harsh chemicals or abrasive cleaners as they can cause damage to the aluminum. 2. Next, immerse a soft sponge or cloth into the cleaning solution and gently scrub the surface of the aluminum sheets. It is necessary to ensure that the entire surface is covered, with special attention given to any stains or dirt build-up. 3. In the case of stubborn stains or grime, a non-abrasive brush or toothbrush can be used to scrub the affected areas. However, caution should be exercised to prevent applying excessive pressure, as this may result in scratching the aluminum. 4. Following the cleaning process, the sheets should be thoroughly rinsed with clean water to eliminate any residue from the cleaning solution. It is important to ensure that all soap is completely rinsed off. 5. Once rinsed, a clean and dry cloth should be used to remove any excess water and dry the aluminum sheets. This step aids in preventing water spots or stains from forming. 6. To preserve the shine and condition of the aluminum, a thin layer of aluminum polish or wax can be applied. It is advisable to follow the manufacturer's instructions for the best outcomes. 7. Regular inspection of the aluminum sheets is recommended to detect any signs of damage, such as dents, scratches, or corrosion. If any issues are noticed, they should be promptly addressed to prevent further harm. It is crucial to handle aluminum sheets with care to avoid damage. The use of abrasive materials, sharp objects, or harsh chemicals that can scratch or corrode the surface should be avoided. Regular cleaning and maintenance will assist in preserving the appearance and prolonging the lifespan of the aluminum sheets.

- Q: What are the different types of coatings available for aluminum sheets?

- There are several different types of coatings available for aluminum sheets, each offering unique properties and benefits. 1. Anodized Coating: Anodizing is a popular coating method that involves immersing the aluminum sheet in an electrolyte bath and passing an electric current through it. This process creates a durable and corrosion-resistant layer of oxide on the surface of the sheet. Anodized coatings can come in various colors and offer excellent abrasion resistance. 2. Powder Coating: Powder coating involves applying a dry powder to the aluminum sheet and then curing it under heat. This coating method provides a durable, uniform, and attractive finish. Powder coatings are available in a wide range of colors and textures and offer excellent resistance to chipping, scratching, and UV fading. 3. Paint Coating: Aluminum sheets can also be coated with liquid paint. This method provides versatility in terms of color choices and finishes. Paint coatings offer good resistance to weathering, impact, and chemicals, but they may not be as durable as anodized or powder coatings. 4. Cladding: Cladding is a process in which a layer of a different metal, such as stainless steel or copper, is bonded to the aluminum sheet surface. This provides added protection, improved aesthetic appeal, and can enhance the sheet's mechanical properties. 5. Laminating: Laminating involves bonding a protective layer, such as a film or sheet, onto the surface of the aluminum sheet. This coating method offers protection against abrasion, UV rays, and chemicals, and can also provide decorative finishes. 6. Organic Coating: Organic coatings, such as polyurethane or acrylic coatings, are applied to aluminum sheets to provide protection against corrosion, weathering, and chemical exposure. These coatings offer flexibility, good adhesion, and a wide range of color choices. Overall, the choice of coating for aluminum sheets depends on the specific requirements of the application, such as durability, corrosion resistance, aesthetic appeal, and cost-effectiveness.

- Q: Can aluminum sheets be embossed?

- Yes, aluminum sheets can be embossed.

- Q: Are the aluminum sheets suitable for automotive applications?

- Indeed, automotive applications can make use of aluminum sheets. Being a lightweight material with a high strength-to-weight ratio, aluminum proves to be an excellent choice for the automotive industry. Its attributes lend themselves well to this industry, offering numerous benefits such as enhanced fuel efficiency, improved handling, and increased performance. Furthermore, aluminum's resistance to corrosion is advantageous for automotive applications, as it contributes to the longevity of vehicles. Furthermore, aluminum sheets possess the ability to be easily shaped and molded into various forms, which grants automotive manufacturing greater design flexibility. In conclusion, the utilization of aluminum sheets in automotive applications has gained popularity due to their myriad advantages and their positive impact on vehicle performance and sustainability.

- Q: For example, in hydrangeas, when aluminum reacts with the anthocyanins in the flower's petals, the hydrangeas turn blue, but what chemical reaction occurs?

- Two factors affect the color in Hydrangea macrophylla cultivars: soil acidity and the presence of aluminium in the soil. To obtain a blue hydrangea, aluminum must be present in the soil. The pH of the soil should be low (4 - 4.5). In alkaline soil aluminium is tied up. The plants are unable to absorb the existing aluminium and the flowers will not bloom blue. Also, when aluminium in the soil is used up the flower color will be red or pink again. If the soil is watered with aluminium salts aluminium is accumulated in the petals and the color turns blue. Only red and pink colored Hortensis are suitable for the breeding of blue flowers. They contain the dye component delphinidin. At the end of this site you find explanation and the formula: www.uni-regensburg.de/Fakultaeten...

- Q: This question asks for a comparison between aluminum sheets and other lightweight materials like plastic and glass, focusing on their properties and uses.

- <p>Aluminum sheets are lightweight yet strong, offering excellent strength-to-weight ratios. They are more durable and heat resistant compared to plastics, which can deform under heat and are less sturdy. Unlike glass, aluminum is less brittle and does not shatter, making it safer for certain applications. Additionally, aluminum is recyclable and has good thermal and electrical conductivity, which is not the case with plastics. However, plastics are generally cheaper and easier to shape into complex forms, while glass offers better transparency for applications requiring clear visibility. Each material has its advantages depending on the specific requirements of the application.</p>

- Q: Are aluminum sheets suitable for marine hulls?

- Yes, aluminum sheets are suitable for marine hulls. Aluminum is lightweight, durable, and corrosion-resistant, making it an excellent choice for boat hull construction. It offers good strength-to-weight ratio, enhances fuel efficiency, and requires less maintenance compared to other materials.

Send your message to us

China Colored Anodized Aluminum Grating for Suspended Ceiling Galvanized or Painted

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords