Aluminum Galvanized Sheets with Best Price in Our Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

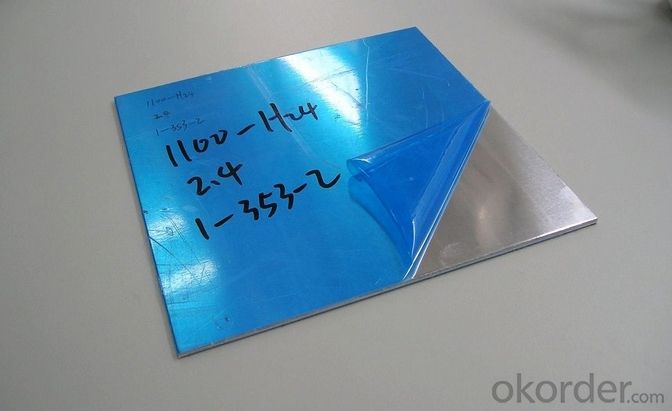

1.Structure of Product Description

hot rolled and cold drawn and cold rolled aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series,5000 series,7000series, 8000 series, etc. The detailed grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

c. Shortest service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm,1220mm*2440mm,1219mm*2438mm,1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range:

---It is from 2000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 5 tons/each size.

How many tons did you export in one year?

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from UAE, Saudi Arabia, England,Turkey,Japan, etc.

What is your mainly products?

---Normally they are aluminum sheet,big-5-bar aluminium checkered sheet,small-5-bar aluminium checkered sheet,mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: (1) Aluminum is malleable. (2) Aluminum reacts with sulfuric acid.(3) Aluminum conducts an electric current.(4)Aluminum has a density of 2.698 g/cm3 at STP.Explain why.

- The answer is statement 2 Reasons why: First, know that a chemical property of any element is something that results in the change of the chemical make-up of the element. The word for word definition in my textbook says: a chemical property is the ability of a substance to combine with or change into one or more substances through a change in the chemical formula for the substance Looking at all the other options: Statement 1: Whether or not a substance is malleable is whether or not a substance can be hammered or pressed out of shape and not break or shatter. Hammering a substance, or in this case Aluminum, does not change any chemical formula of Aluminum, it just changes the physical shape of the metal. Statement 3: If a substance is conductive of electricity, it means that the material can transport an electric current. This is not chemical because the electricity simply goes through the substance, it does not change or react with any of the atoms of a substance and change the chemical formula. Statement 4: Density is a purely physical property because it is how dense a material is, and it doesn't change the formula of a substance. Therefore, Statement 2 is the best answer because by reacting with sulfuric acid, the chemical formula of aluminum changes since the atoms recombine with the atoms of sulfuric acid and create a new substance and a new chemical formula with it.

- Q: How does the surface roughness affect the friction properties of aluminum sheet?

- The surface roughness of an aluminum sheet affects its friction properties by increasing the surface area in contact with another object, leading to higher frictional forces. A rougher surface will have more irregularities and asperities, creating more points of contact and interlocking with the opposing surface. This increased contact area enhances the adhesion between the surfaces, resulting in higher friction. Conversely, a smoother surface with fewer irregularities will have reduced contact area and less adhesion, leading to lower friction.

- Q: Can aluminum sheets be used for decorative or architectural purposes?

- Yes, aluminum sheets can be used for decorative or architectural purposes. Due to their lightweight, durability, and versatility, aluminum sheets are commonly used in architectural design and construction for applications such as cladding, roofing, facades, and decorative elements. They offer various finishes, patterns, and colors, making them suitable for enhancing the aesthetic appeal of both interior and exterior spaces. Additionally, aluminum sheets are resistant to corrosion and require minimal maintenance, making them a popular choice for decorative and architectural purposes.

- Q: I've narrowed down my next bike next year to either the cannondale Caad10 Ultegra version or the supersix 105 version, I've heard good things about both bikes, and at this point its gonna be down to preference after I ride it but, is aluminum stronger than carbon or vice versa? Will carbon crack easily or fail catastrophically?

- I would prefer carbon over aluminum I would agree with Anna on her post If you plan on touring carbon is a poor choice. If touring is a goal I would prefer steel over aluminum While I have not chosen Aluminum as my number one choice in either I would also say that it is a fantastic material for a bike frame. My mountain bike is an aluminum alloy and I love that bike. I have owned both for road bikes and like my carbon better and not by a little bit. to be fair my aluminum bike was not the same quality as my carbon. Sora vs Ultegra and a host of little differences. On the road I have found aluminum stiff and unforgiving compared to carbon which is stiff and forgiving. Most bikes come with carbon forks for that reason. Cannondale is a fine machine and I would be proud to own either bike. My daughter rides a Synapse which is an aluminum frame. As far as durability I have had no issues with carbon. My bike gets between 60-100 miles every week and often much more and has no signs of cracks and or other issues. For those that say the lifespan of carbon is ten years I am uncertain if that is true. However most Rec Riders components on a bike have seen enough use after ten years to warrant a new bike at that point.

- Q: What are the different grades or alloys of aluminum available for sheets?

- Aluminum sheets come in various grades and alloys, each with its own unique properties. Grade 3003, for example, is widely used and offers good corrosion resistance and moderate strength. It finds applications in general sheet metal work, cooking utensils, signage, and chemical equipment. On the other hand, grade 5052 is known for its excellent corrosion resistance and high strength. It is often utilized in marine applications like boat hulls and components, as well as aircraft parts and transportation equipment. Grade 6061 is a versatile aluminum grade that combines strength, weldability, and machinability. It is commonly chosen for structural components such as frames, railings, and automotive parts. It is also frequently employed in the architectural field for construction purposes. Apart from these grades, there are numerous specialized aluminum alloys available for specific applications. These alloys may possess enhanced characteristics like improved strength, heat resistance, or electrical conductivity. Examples of such alloys include 2024, 7075, and 6063. When choosing the appropriate aluminum sheet grade or alloy, it is crucial to consider factors such as desired strength, corrosion resistance, formability, and specific application requirements. Seeking advice from a knowledgeable supplier or expert can ensure the correct grade of aluminum is selected for the intended usage.

- Q: Can aluminum sheets be welded or soldered?

- Yes, aluminum sheets can be welded or soldered.

- Q: I have tried every possible method that I could find on the web for cleaning aluminum, tungsten, filler wire. Nothing has seemed to work. I've tried looking for leaks in the argon line. I'm getting decent welds but there is gunk in the welds for sure. I'm worried about overall strength of the welds. Does anybody out there know of a tried and true method for cleaning aluminum, tungsten, filler etc. that is sure to work? If I can follow that method and still have problems It could possibly be a problem with the machine. Any help would be much appreciated.

- Preweld cleaning requires two operations: oil/grease removal and oxide removal. As below, remove oils and greases first, then remove the oxide. Don’t reverse this order. Take the following steps before welding aluminum: 1. Remove oil, grease, and water vapor using an organic solvent such as acetone or a mild alkaline solution like a strong soap. You may also use citrus-based degreasers, but be sure to rinse and dry the part before welding. 2. Remove surface oxides with a stainless steel wire brush (used only for aluminum) or strong alkaline or acid. Many welding suppliers sell oxide-removal solutions in spray or squeeze bottles for local application. Exercise extreme care when handling these solutions, and again, rinse and dry the part before welding. 3. Assemble the joint. If it won't be welded immediately, cover the joint with brown Kraft paper to prevent dirt and grit in the air from getting into the joint. 4. Keep the aluminum dry and at room temperature. 5. Weld within a few days. Clean the joint again if it isn't welded within that time. Good luck!!!

- Q: you can turn in aluminum cans for cash some are called golden goats

- Aluminum okorder

- Q: Can the aluminum sheets be used for manufacturing chemical reaction vessels?

- Yes, aluminum sheets can be used for manufacturing chemical reaction vessels. Aluminum is a versatile material that offers several advantages for this purpose. It is lightweight, durable, and has excellent corrosion resistance, making it suitable for containing various chemicals and reacting with them. Moreover, aluminum is relatively easy to shape and form into the desired vessel design, allowing for flexibility in manufacturing. However, it is important to note that aluminum may not be suitable for all chemical reactions, especially those involving highly corrosive or reactive substances. In such cases, alternative materials that can withstand the specific reaction conditions may be more appropriate.

- Q: What is the typical thermal expansion coefficient of aluminum sheets?

- The typical thermal expansion coefficient of aluminum sheets is approximately 22.2 x 10^-6 per degree Celsius.

Send your message to us

Aluminum Galvanized Sheets with Best Price in Our Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords