Aluminum-frame for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

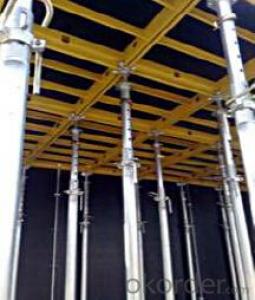

Aluminum-frame Formwork

Characteristics:

◆ The complete formwork system for slab casting, easy & quick assembly.

◆ Light panel weight, easy to carry.

◆ Economical, versatile & hi-speed formwork system; comes with a permissible slab

thickness of 400 mm.

◆ Working efficiency is greatly improved by fast erection and dismantlement.

◆ The panel can be supported by both props and scaffolding.

◆ High standardization with components.

- Q: Can steel formwork be used for hotel construction projects?

- Indeed, hotel construction projects can make use of steel formwork. This adaptable and enduring solution is ideal for the creation of concrete structures, including hotels. It boasts numerous benefits, including exceptional strength, durability, and the ability to be reused. Steel formwork can withstand the immense pressure exerted by wet concrete and can be effortlessly assembled and disassembled, making it highly suitable for a range of construction endeavors, such as hotels. Moreover, it imparts a sleek and precise finish to concrete structures, guaranteeing construction of the utmost quality.

- Q: Can steel formwork be used for both standard and non-standard concrete shapes?

- Yes, steel formwork can be used for both standard and non-standard concrete shapes. Steel is a versatile material that can be easily molded and shaped to create various formwork designs. It offers high strength and durability, making it suitable for complex and intricate concrete shapes. Steel formwork can be fabricated to meet specific project requirements, allowing for customization and flexibility in formwork design. Whether it is a standard rectangular shape or a unique and irregular design, steel formwork can be used effectively to mold and shape concrete structures of any shape and size.

- Q: Can steel formwork be easily transported to different job sites?

- Indeed, steel formwork can effortlessly be transported to various worksites. Renowned for its sturdiness and robustness, steel formwork is ideal for repeated utilization and convenient transportation. It can be dismantled and reassembled without compromising its structural soundness, enabling effortless transportation to diverse destinations. Furthermore, unlike alternative formwork types, steel formwork is lightweight, rendering it more manageable to handle and transport using conventional construction machinery or vehicles. The adaptability and portability of steel formwork render it an esteemed preference for construction ventures necessitating frequent relocation between worksites.

- Q: What are the common safety precautions when working with steel formwork in high winds?

- When working with steel formwork in high winds, there are several common safety precautions that should be followed to ensure the safety of workers and the integrity of the formwork. 1. Secure the formwork: It is essential to properly secure the steel formwork to prevent it from being blown away by strong winds. This can be achieved by using appropriate anchoring methods such as tie-downs, braces, or clamps. Adequate bracing should be installed at regular intervals to provide additional stability. 2. Regular inspections: Regular inspections of the formwork should be conducted before, during, and after high wind events. This includes checking for any signs of damage or weakness in the formwork structure, loose connections, or compromised anchoring. Any issues identified should be addressed promptly to prevent accidents or further damage. 3. Reinforce the formwork: In areas with high wind activity, it may be necessary to reinforce the steel formwork to withstand the stronger forces. This can be done by adding additional support beams, cross-bracing, or wind-resistant features to the structure. The reinforcement should be designed and implemented by a qualified engineer to ensure its effectiveness. 4. Provide personal protective equipment (PPE): Workers should be provided with appropriate personal protective equipment to protect them from potential hazards during high wind conditions. This may include safety helmets, goggles, gloves, and high-visibility clothing to enhance visibility for other workers and equipment operators. 5. Monitor weather conditions: Regular monitoring of weather conditions is crucial when working with steel formwork in high winds. If there are predictions or signs of strong winds, work should be temporarily suspended until the wind speeds decrease to safe levels. It is important to have a reliable weather monitoring system in place to stay informed about changing weather conditions. 6. Training and communication: All workers involved in working with steel formwork should receive proper training on the safety precautions and procedures to follow during high wind situations. Clear communication channels should be established to ensure that workers are aware of any changes in weather conditions or safety protocols. By following these common safety precautions, the risks associated with working with steel formwork in high winds can be minimized, ensuring the well-being of workers and the successful completion of the construction project.

- Q: Can steel formwork be used in areas with limited construction access roads?

- Yes, steel formwork can be used in areas with limited construction access roads. Unlike traditional formwork made of wood or other materials, steel formwork is durable, lightweight, and can be easily transported to remote locations. It can be disassembled and reassembled multiple times, making it suitable for areas with limited access roads where transportation of heavy construction materials is challenging. Additionally, steel formwork offers high strength and stability, ensuring the structural integrity of the construction even in difficult-to-reach areas.

- Q: Can steel formwork be used for precast concrete facades with intricate patterns?

- Yes, steel formwork can be used for precast concrete facades with intricate patterns. Steel formwork is highly versatile and can be custom-designed to create complex shapes and patterns, allowing for the creation of intricate facades. Additionally, steel formwork provides excellent strength and durability, making it suitable for handling the weight and pressure of precast concrete.

- Q: Can steel formwork be used for tall structures?

- Indeed, tall structures can be constructed using steel formwork. With its versatility and durability, steel formwork proves to be an excellent option for erecting towering buildings. Its notable advantages, including high strength, rigidity, and stability, make it the ideal choice for such structures. The ability of steel formwork to withstand the immense pressures exerted by fresh concrete ensures a smooth and uniform surface finish. Moreover, its reusability not only reduces construction costs but also minimizes the environmental impact. Furthermore, steel formwork allows for precise customization and effortless adaptation to various architectural designs and structural requirements. In conclusion, when it comes to constructing tall structures, steel formwork stands as a dependable and efficient solution.

- Q: How does steel formwork affect the overall construction productivity?

- Steel formwork is a construction technique that utilizes metal panels and supports to create temporary molds or frames for pouring concrete. This method offers several advantages over traditional timber formwork, including enhanced durability, reusability, and flexibility in design. Consequently, steel formwork significantly affects the overall construction productivity in multiple ways. Firstly, steel formwork contributes to increased construction efficiency by reducing the time required for formwork assembly and dismantling. Unlike timber formwork, steel panels are prefabricated and easily interconnected, allowing for swift installation and disassembly. This results in reduced labor hours and faster completion of formwork activities, ultimately accelerating the construction process. Moreover, the durability of steel formwork positively impacts productivity. Steel panels can withstand harsh weather conditions, extreme temperatures, and heavy loads, ensuring their longevity and reusability. As a result, contractors can reuse steel formwork on multiple projects, eliminating the need for frequent replacement and reducing material costs. The ability to reuse formwork not only saves time and money but also minimizes waste generation and promotes sustainability in the construction industry. Additionally, steel formwork offers greater flexibility in design, enabling the construction of complex structures with precision. The modularity and adjustability of steel panels allow for easy customization according to project requirements, resulting in accurate and consistent concrete placements. This precision eliminates the need for excessive concrete rework, reducing material waste and saving construction time. The speed and accuracy provided by steel formwork positively impact overall construction productivity. Furthermore, steel formwork enhances safety on construction sites. Its sturdy structure and secure connections ensure stability during concrete pouring, minimizing the risk of accidents or structural failures. This increased safety reduces downtime caused by injuries or damages, ultimately improving productivity by maintaining a continuous workflow. In conclusion, steel formwork significantly affects overall construction productivity through various means. Its quick assembly and dismantling, durability, reusability, flexibility in design, and improved safety contribute to faster construction processes, reduced material waste, and enhanced efficiency. Embracing steel formwork techniques can lead to significant time and cost savings, ultimately benefiting the construction industry as a whole.

- Q: How does steel formwork affect the aesthetics of a building?

- The aesthetics of a building can be significantly impacted by steel formwork in various ways. Firstly, steel formwork allows for the creation of complex and intricate designs, resulting in visually appealing architectural elements. The flexibility and strength of steel enable the construction of unique shapes, curves, and patterns that enhance the overall aesthetics of the building. Moreover, steel formwork gives concrete surfaces a smooth and seamless finish. This contributes to a more refined and polished appearance, especially when compared to other formwork materials like timber or plastic. The absence of visible joints, seams, or imperfections on the concrete surfaces enhances the overall look of the building. Additionally, steel formwork offers the advantage of reusability, leading to cost savings and reduced waste. This economic benefit allows architects and designers to allocate more resources to enhance the building's aesthetics, such as incorporating high-end finishes or unique decorative elements. Furthermore, steel formwork ensures a high level of accuracy and precision during the construction process. This precision guarantees that the final structure is aligned and symmetrical, enhancing the overall visual harmony of the building. Straight lines, sharp corners, and consistent dimensions can be achieved with steel formwork, resulting in a visually pleasing and harmonious architectural design. Lastly, the durability and strength of steel formwork contribute to the long-term aesthetics of the building. Steel formwork can withstand harsh weather conditions, resist corrosion, and maintain its structural integrity over time. This durability ensures that the building's aesthetics remain intact for an extended period, enhancing its overall appeal and value. To conclude, steel formwork has a positive impact on the aesthetics of a building by enabling complex designs, providing a smooth finish, allowing for precision and accuracy, offering cost savings, and ensuring long-lasting visual appeal.

- Q: Can steel formwork be used for both flat and sloped concrete surfaces?

- Yes, steel formwork can be used for both flat and sloped concrete surfaces. Steel formwork is highly versatile and can be easily adjusted and shaped to accommodate different angles and slopes during the concrete pouring process. Its strength and rigidity make it suitable for supporting the weight and pressure of the concrete, ensuring a smooth and uniform finish regardless of the surface inclination.

Send your message to us

Aluminum-frame for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords