Aluminum Foil with PET and LLDPE for Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg/m³

- Supply Capability:

- 500000 kg/m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Aluminum Foil Facing Description:

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

• FSK aluminum foil facing is mainly used for duct wrap in HVAC system and other fields, such as vapor barrier etc., and suitable for off-line lamination of glass wool or rock wool. By special processing, the facing will have excellent flame retardant property.

• Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination of glass wool and rock wool.

• The WPSK aluminum foil facing, whose structure is white polypropylene/ fiberglass scrim/ kraft is mainly used for metal building insulation and suitable for the insulation of ware-house, factory, supermarket, office and so on.

2.Main Features of the Aluminum foil facing:

• Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

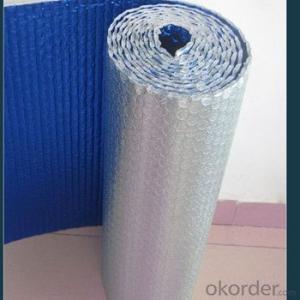

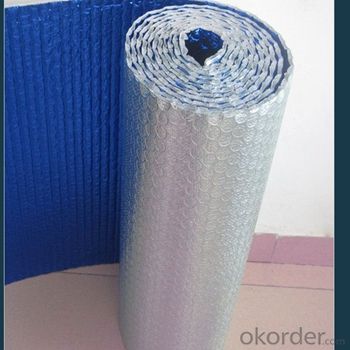

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 80 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 95 50 | ASTM C1136 |

Burst strength | N | 25 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C +66°C | No change keep soft | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Water Soak Test | 24hrs | No delamination | ---------- |

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

(1) How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

(2)What is the storage condition?

The products should be stored at room temperature and kept from wet and heat source.

It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

- Q: How safe is your slice of graphite?

- Organic or inorganic glass lenses, various metal, electroplating plates, stainless steel, aluminum profiles, steel plastic profiles, aluminum plastic panels, glass panels, various types of paint panels, high-grade furniture, stone and other materials surface protectionIn addition to Dongguan, East America's protective film is the best, I really can not remember who else

- Q: What does thickness C of the base material of protective film stand for?

- It's just a terminology about thickness in industry. 5 c = 50 um = 0.05 mm.

- Q: Is original iPad coated with a protective film?

- No. And I suggest you'd better not buy one.

- Q: How to tear off the aging protective film on the security door?

- Wipe it off using cloth with some water.

- Q: What kind of material is acrylic protective film made from?

- Usually, the protective film used on acrylic panels and sheets is made from PE materials.

- Q: What kind of protective film can cover the matte surface?

- The glue of the film must be thick, as least 0.03mm.

- Q: Cover the surface of metal plate with protective film.

- The film itself may be coated with a layer of glue. Thus it's no need to use other adhesive tapes. If you use double-sided adhesive tape, I recommmend this kind. This kind of tape won't fall off even if it ages owing to damp and high temperature. If the film feels not adhesive, it doesn't mean it's not coated with glue because generally, the adhesion of protective film is very low that you can hardly feel it.

- Q: The protective film on the top of the stainless steel is torn and sticky

- 5, with banana water. Is used to remove paint an industrial agent, it is very easy to buy (sell paint there is a place to sell). The method is the same as alcohol acetone. With a hot towel in the scraping blade and eraser very clean home. Fengyoujing. It's a good thing, and it can easily solve your problem. Pay more attention to your life. I hope I can help you

- Q: How to remove the protective films on electrical appliances after using for a long time?

- The best method: Using absolute ethyl alcohol (purity is more than 99% ) to wipe the electric appliance and tear the film while wiping.

- Q: How do I get the protective film for the kraft paper on the plastic board?

- From the beginning of a corner, slowly with a nail to pull from the corner, then slowly tear, while tear tear in the side roll, some local glue is tight, fingernails, to be up to 6, the 7 lap will be able to hand held, will be able to slowly tear the whole. The key is not to worry, where there are sticky tight place, stop with a nail scratch, not hard to drag.

Send your message to us

Aluminum Foil with PET and LLDPE for Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg/m³

- Supply Capability:

- 500000 kg/m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords