Aluminum Foil Sheets Dollar Tree - Aluminium Cold Drawn Sheet with Good Price in Warehouse

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

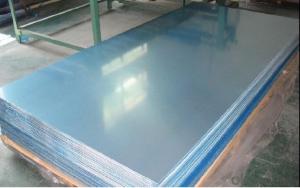

1.Structure of Product Description

our best-selling goods are including aluminium cold rolled sheet and hot rolled aluminum checkered sheet, and also the cold drawn aluminium hseet , and also the color coated alumnium coil, etc. Alloy number and temper are as follows: 1000 series, 2000 series, 3000 series, 7000 series, 8000 series,etc. The detailed grade are as follows: 1010, 2024,3003, 3105,6063,7075,8011,etc.

With the temper are as follows: H14, H22, H24, H44,H112,etc.

2. Main features of the product

a. the best-discount price

c. Shortest service and delivery time.

3. Image.

4. Product detailed sizes:

1000mm*2000mm,1500*3000mm,1219mm*2438mm, at random sizes,etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 200mm to 8000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 4 tons/each size.

How many tons did you export in one year

Indonesia,Canada,sri lanka,bangladesh,pakistan, Vietnam,Turkey,etc.

What is your mainly products?

---Normally they are aluminum sheet,small-5-bar aluminium checkered sheet, big-5-bar checkered aluminium plate, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: What are the different methods of surface patterning aluminum sheets?

- There are several methods available for surface patterning aluminum sheets, each with its own advantages and applications. Some of the commonly used methods include: 1. Mechanical Etching: This method involves the use of abrasive materials, such as sandpaper or wire brushes, to create patterns on the surface of the aluminum sheet. By applying varying pressure and movement, desired patterns can be achieved. Mechanical etching is a cost-effective and versatile method, suitable for creating simple to complex patterns. 2. Chemical Etching: Also known as chemical milling, this method uses chemicals to selectively remove material from the aluminum surface, creating patterns. The aluminum sheet is coated with a resist and then immersed in an etchant solution that dissolves the exposed areas, leaving behind the desired pattern. Chemical etching allows for precise and intricate designs but requires careful control of the etching process. 3. Laser Engraving: This method utilizes a high-power laser beam to remove material from the aluminum surface and create patterns. The laser beam is controlled by computer software, allowing for precise and detailed designs. Laser engraving is suitable for both small and large-scale production and offers high accuracy and repeatability. 4. Embossing: In this method, the aluminum sheet is pressed between two dies that have raised patterns, creating a three-dimensional design on the surface. Embossing can be done through mechanical or hydraulic presses and is commonly used to add texture and aesthetic appeal to aluminum sheets, such as for decorative purposes or branding. 5. Printing: Various printing techniques can be used to apply patterns onto aluminum sheets. These include screen printing, where ink is forced through a mesh screen onto the aluminum surface, and digital printing, which uses inkjet technology for high-resolution patterns. Printing methods allow for a wide range of colors and designs, making them suitable for decorative applications. The choice of surface patterning method depends on factors such as the desired pattern complexity, production volume, cost considerations, and the intended end-use of the aluminum sheets. Each method offers unique advantages and limitations, and manufacturers can select the most appropriate technique based on their specific requirements.

- Q: Can the aluminum sheets be used for solar panel frames?

- Yes, aluminum sheets can be used for solar panel frames. Aluminum is a preferred material for solar panel frames due to its lightweight, durable, and corrosion-resistant properties. It provides structural stability and ease of installation for the solar panels.

- Q: need help choosing an aluminum welder at a descent price also

- i think, welding,,, tig is right machine for aluminum, thank you.

- Q: I have a lot of old aluminum cake pans, coffee pots, pots and pans and various old nuts and bolts made of aluminum. Would it be worth it to scrap them? They really aren't usable for cooking anymore. They are clean.

- Aluminum is currently scrap priced at eighty cents per pound. If you have enough to justify the gasoline to go to a scrap yard, yes it is worth it. Your scrap will end up in Japan rather than in a landfill.

- Q: Other then pop cans, what else is aluminum that can be recycled?

- all of it.

- Q: Can aluminum sheets be custom cut to specific sizes?

- Yes, aluminum sheets can be custom cut to specific sizes according to the requirements of the project or application.

- Q: Can aluminum sheets be stamped or engraved?

- Yes, aluminum sheets can be stamped or engraved.

- Q: What are the different methods of cutting aluminum sheet?

- Some of the different methods of cutting aluminum sheet include using shears, bandsaws, jigsaws, circular saws, laser cutting, and waterjet cutting.

- Q: This question asks whether it is possible to utilize stamped or embossed aluminum sheets for a specific project.

- <p>Yes, you can use stamped or embossed aluminum sheets in your project. These sheets are known for their strength, durability, and lightweight properties, making them ideal for various applications such as construction, automotive, and aerospace. Stamped aluminum sheets are formed by pressing the material into a specific shape, while embossed sheets have a raised pattern. Both types offer design flexibility and can be customized to meet specific project requirements. Ensure that the aluminum sheets you select meet the necessary specifications for your project, such as thickness, strength, and finish.</p>

- Q: Can aluminum sheet be used for cookware?

- Indeed, cookware can indeed employ aluminum sheets. Aluminum, being renowned for its superb heat conductivity, facilitates even heat dispersion and rapid heating. It possesses the attributes of being lightweight, long-lasting, and impervious to rust and corrosion. Moreover, aluminum cookware is reasonably priced and comparatively effortless to maintain. Nevertheless, pure aluminum proves to be a malleable metal, thus necessitating its amalgamation with other substances such as stainless steel or nonstick coatings to fortify its endurance and nonstick qualities.

Send your message to us

Aluminum Foil Sheets Dollar Tree - Aluminium Cold Drawn Sheet with Good Price in Warehouse

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords