Glass Wool Roofing and Partition Wall Blanket

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 100000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Glass Wool Blanket For Insulation

INTRODUCTION

In the field of insulation materials, weare mainly specializing in Glass wool products, including blankets, boards andpipes. The advantage of this material is numerous: noncombustible, nontoxic,and resistant to corrosion. It has low weight, low thermal conductivity, stablechemical property, low moisture rate and good hydrophobicity. These productshave been widely used in heat preservation, thermal insulation and soundabsorption in construction, chemical industry, electronic industry, electricpower, metallurgy, energy industry, and communication. High density panelslaminated with facing can be used for Air-conditioning duct system.

The Kinds of Glass Wool Insulation

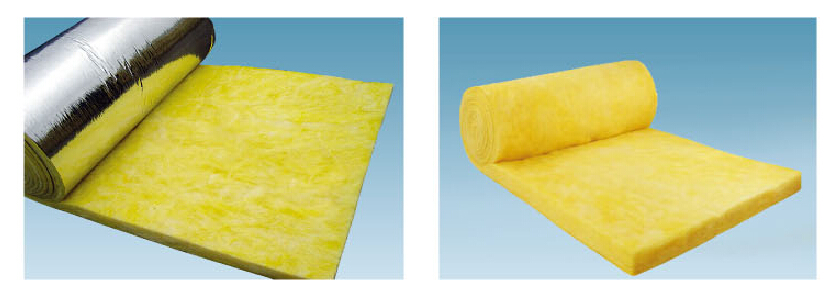

* glass wool blanket plain or with Aluminum foil -clad(Kraft paper or white PVC/WPSK)

* glass wool board

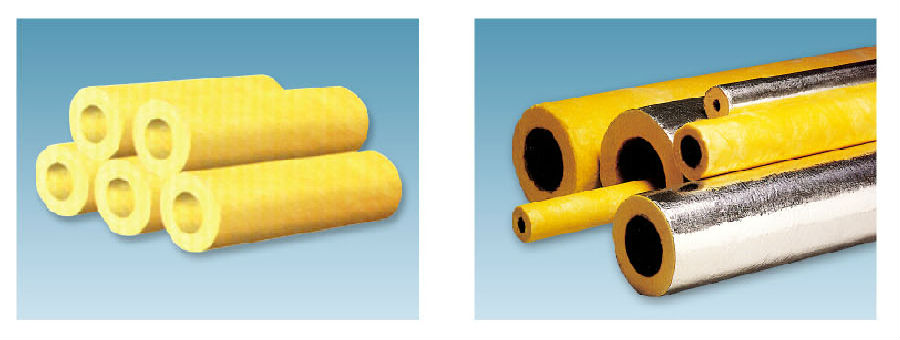

* glass wool pipe

Our Advantage

* Short delivery time

* Origin of China, FROM A / E/ F

* Stable good quality with competitive price (CE certificate)

TECHNICAL DATA

Item | Unit | Index |

Density | Kg/m3 | 10-100 |

Average Fiber Diameter | μm | 5-7 |

Water Content | % | ≤1 |

Grade of Combustibility | Non-Combustible Grade A | |

Reshrinking Temp | ℃ | ≥250 |

Thermal Conductibility | w/m.k | 0.038-0.06 |

Hydrophobic | % | ≥98 |

Moisture Rate | % | ≤5 |

Noise Resistant Coefficient (NRC) | 0.75 | |

Slag Inclusion Content | % | ≤0.3 |

CE CERTIFICATE

Glasswool Blanket

Introduction

The glass wool blanket is applied for largelaying area. Besides the character of thermal insurance, it also has theperformances of shock absorption and acoustical isolation, especially for middleor low frequency sound. It also can cancel the noise and improve workingenvironment.

The glass wool blanket with aluminum foilsurface has good capability of heat radiation protection.

TechnicalData

Item | Unit | Index |

Density | Kg/m3 | 10-32 |

Thickness | mm | 25-150 |

Width | mm | 600-1200 |

Length | mm | 10000-30000 |

Note: Product with special specificationcan be made to order.

Both unfaced and faced felts can beprovided.

Application

This material can be freely cut inconstruction according to the shape required, mainly used in room,noise-canceling system, transportation, refrigerators and household electricappliances for noise canceling.

The blanket with aluminum foil is suitablefor high temperature shops, control room, inner wall of the machine shops, roomseparating and inner liners.

Package

Normal packing: Each roll is wrapped withvacuum plastic bag, and then in PE woven bag.

Special required package like PE BAG and PESHRINKED BAG can be made with additional charge.

Glasswool Pipes

Introduction

As this material has the characters ofwater-proof, anti-corrosion and mildewing-proof, glass wool pipe is good atstopping condensation and freezing of the pipes.

TechnicalData

Item | Unit | Index |

Density | Kg/m3 | 48-96 |

Thickness | mm | 25-90 |

Diameter | mm | 18mm-529mm(3/4 inch to 21 inch) |

Length | mm | 1 000,1 200 |

Note: Product with special specificationcan be made to order.

Both unfaced and faced felts can beprovided.

Application

It is widely used in building, heating powerpipes, air conditioning and refrigerators for thermal insurance, such as hotwater pipes, steam pipes, electric power, petroleum and chemical industries.

Glass wool pipe faced with Alum Foil can beapplied to the surface for preventing moisture and radiation.

Package

Reasonable pieces will be packed withplastic bags or carton box, and then into container.

Glasswool Boards

Introduction

Glasswool board is a kind of plate productwith fixed strength after hot-setting of the centrifugal glass wool. It hasexcellent thermal insurance performance in the environment of both high and lowtemperature.

TechnicalData

Item | Unit | Index |

Density | Kg/m3 | 24-96 |

Thickness | mm | 20-100 |

Width | mm | 600-1 200 |

Length | mm | 1 200,2 400 |

Note: Product with special specificationcan be made to order.

Both unfaced and faced felts can beprovided.

Application

It is mainly used for the partition wall inthe high-grade building, such as ceiling, air conduit and inner wall forthermal insurance, machine shops for noise absorption, and metal ceiling forcontrol of moisture.

High density panels with laminated facingcan be used for Air-Conditioning Duct System.

Package

Reasonable pieces will be packed withplastic bags, and then into container.

- Q: What are the raw materials of centrifugal glass wool?

- The main raw materials of good centrifugal glass wools which are made of industrial chemicals like borax are natural ores like quartz sand, limestone, and dolomite, with some pure alkali.

- Q: is glass wool fireproof?

- A class fireproofing and hydrophobic.

- Q: what is the quota of glass wool rigid section of thermal insulation.

- what is the meaning of your words! are you asking the size! (I am a thermal insulation material wholesalers and if you have any questions please ask me)

- Q: Rock wool board and glass?wool?board, which is more harmful to human body?

- Rock wool board, rock wool board has more layers!

- Q: Are fireproof glass wool and centrifugal glass wool the same?

- Bububububububububuubububububb

- Q: Does anyone know about the general unit weight of glass cotton color steel?plate?

- Glass cotton is the general term of fibrous silicate minerals which can be split into long and narrow flexible fibers. Glass cotton are manufactured to meet the requirement of large-area pave, apart from the unique thermal insulation property, they are good at fireproofing, shock and sound absorption which help to reduce noise pollution, and improve working environment. The thickness of rock wool board : 40 to100 mm. The unit weight is 80 to 150kg / m?. Glass wool can be processe into different products. The thickness: 25 to 100mm. The unit weight is 30 to 80kg.

- Q: How to fix centrifugal glass wool felt for steel structure?

- The top of the structure is laid with dedicated barbed wire, and color steel plate is injected and fixed with self-tapping screws. Color steel plate is in the upper layer and glass wool felts laid in the middle.

- Q: does the glass wool can be used as building materials?

- Of course, it can be used as steel structure roofing thermal insulation and also be used as pipe thermal insulation. it can also be used as the central air-conditioner air duct. It belongs to the inorganic insulation material, and widely used in construction. it is also having many applications in the sound insulation and noise reduction.

- Q: Glass wool products can be used for insulation layer

- Glass wool preservative

- Q: What is the construction technology of glass wool felt aluminium expanded sheet sound-absorbent wall?

- The the following details are about the construction technology and practices: Firstly, materials requirements: The main construction materials include asphalt felt, wood keel, gypsum board, glass wool roll mat, glass fiber cloth and perforated aluminum plate. Secondly, technological process: Dry laying a layer of asphalt felt →install wood keel → install gypsum board → paste glass wool felt → pave and nail a layer of glass fiber cloth.

Send your message to us

Glass Wool Roofing and Partition Wall Blanket

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 100000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords