Glass Wool Pipe Insulation - Good Quality Glass Wool Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Glass wool Pipe for thermal Insulation

Introduction

As this material has the characters ofwater-proof, anti-corrosion and mildewing-proof, glass wool pipe is good atstopping condensation and freezing of the pipes.

1.Structure of Glass wool Pipe for thermal Insulation:

Glass wool is an industrial product made by spinning glass into a fibrous material that can be packed in mats and pipes. This product is used as insulation and in other applications, like for air filters.

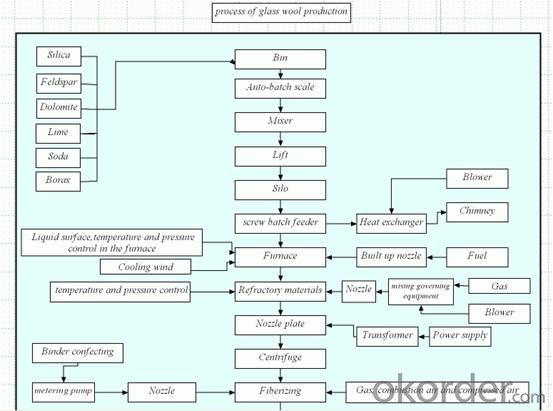

Raw Materials The basic raw materials for fiberglass products are a variety of natural minerals and manufactured chemicals. The major ingredients are silica sand, limestone, and soda ash. Other ingredients may include calcined alumina, borax, feldspar, nepheline syenite, magnesite, and kaolin clay, among others. Silica sand is used as the glass former, and soda ash and limestone help primarily to lower the melting temperature. Other ingredients are used to improve certain properties, such as borax for chemical resistance. Waste glass, also called cullet, is also used as a raw material. The raw materials must be carefully weighed in exact quantities and thoroughly mixed together (called batching) before being melted into glass.

2.Main Features of Glass wool pipe for thermal Insulation:

The glass wool pipe is applied for large laying area. In the field of insulation materials, we are mainly specializing in Glass wool products, including pipes, boards and pipes.

3. Glass wool pipe for thermal Insulation Images

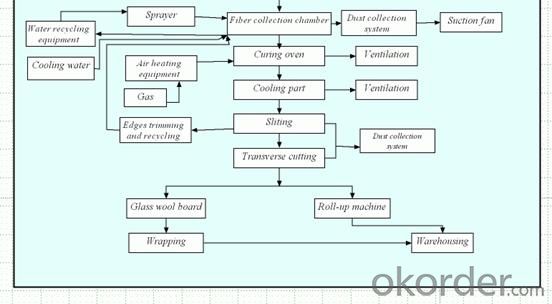

4. Glass wool Processing

5. Glass wool pipe for thermal Insulation Specification

The glass wool pipe is applied for large laying area. Besides the character of thermal insurance, it also has the performances of shock absorption and acoustical isolation, especially for middle or low frequency sound. It also can cancel the noise and improve working environment.

TechnicalData

Item | Unit | Index |

Density | Kg/m3 | 48-96 |

Thickness | mm | 25-90 |

Diameter | mm | 18mm-529mm(3/4 inch to 21 inch) |

Length | mm | 1 000,1 200 |

Both unfaced and faced felts can be provided.

6.FAQ

We have organized several common questions for our clients,may help you sincerely:

① Where you used this?

These products have been widely used in heat preservation, thermal insulation and sound absorption in construction, chemical industry, electronic industry, electric power, metallurgy, energy industry, and communication. High density panels laminated with facing can be used for Air-conditioning duct system.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Does curtain wall glass wool belong to thermal insulation wool?

- I'm very glad to answer for you. Heat preservation wool is a general name of thermal insulation material, aluminum silicate, glass wool, rock wool all can be called as heat preservation wool, these are their differences, glass fiber wool (English name: glass fiber or fiberglass) is an excellent inorganic non-metal material, variety, it's advantage is good insulation, heat resistance, good corrosion resistance, high mechanical strength, but the disadvantages are crisp, poor wear resistance. It is made by taking glass ball or waste glass as raw materials and through high temperature melting, wire drawing, winding, weaving and other manufacturing processes, its monofilament diameter is a few microns to 20 meters microns, equivalent to 1/20-1/5 of a human hair, each bundle original fiber is consisted of hundreds or even thousands of root monofilament. The glass fiber is often used as reinforcing material of composite material, electrical insulation and heat insulation materials, substrate and other national economy fields. Hope my answer will be helpful to you! thanks.

- Q: What are the differences between glass wool and natural cotton? Are there any differences when touching?

- When glass wool touches skin, the skin will get itchy.

- Q: is glass wool fireproof?

- Glass wool is flame retardant or fireproof.

- Q: Now what is the latest color steel sandwich board? such as: Foam, stretches, glass wool

- it is better to use rock wool because it is fireproofing and sound insulation.

- Q: To reach better sound absorption effect, which should be filled in the keel, glass wool felt / board or polyester fiber cotton felt / board ?

- Both materials are inappropriate to used for noise insulation, for glass wool and polyester fiber cotton are sound-absorbing materials. Neither is good for sound insulation. They can be used to prevent echo formation in the room, and their function is to reduce the reflection of sound indoors.

- Q: what's the temperature the high temperature glass wool endure?

- The maximum temperature is 300 degrees.

- Q: Glass wool 159 * 70 What does it mean

- 70 km diameter 159mm.

- Q: Who knows the construction scheme of external wall thermal insulation glass wool ?

- Glass wool external wall thermal insulation construction scheme 2 main material preparation: A, glass wool insulation board (80mm thick) (30mm thick) B, anchorage (8X120) mm plastic rose nail C, sample plate. This place belongs to south podium buildings, where large-scale construction can only be carried out after checking and confirming of supervision main contractor from Party A . 3.6 Pre-construction preparation 3.6.1 Set control lines in necessary parts of the building external wall internal and external corners, holes and deformation joints and rustication. Snap the horizontal ink line on the holes of door and window, and the glass?wool?board in first procedure while controling levelness in construction. Set the horizontal control line in places with two vertical control lines to control the flatness in construction of glass?wool?board. 3.6.2 Except for the solid wall, the wall surfaces should be coated with cement mortar and the flatness, intensity and verticality of mortar surface should meet the requirements of relevant specification. Base plane should be smooth, firm, dry, clean, water and alkali resistance, chalking resistance, PH value

- Q: What are the differences between rock wool and glass wool?

- anti-seismic, etc., using boric acid as the main raw material, felt, rock wool felt, fireproof, different raw materials and process 2, mainly used for thermal insualtion of general building or low temperature piping, glass wool is only about 260 degrees Celsius. Its surface can also paste aluminum foil or PVC film, etc., plate of low shot content, low heat conductivity coefficient, specifications . After high temperature melting, obtaining cotton-like fibers of less than 2um, but the maximum service temperature of rockwool is about 600 degrees Celsius, which can be made into boards. Different applications glass wool is generally used for thermal insulation parts of less than 200 degrees Celsius, rock wool is generally used for thermal insulation parts of 450 degrees Celsius , mainly used for thermal insulation of high temperature heat distribution pipeline or electrical equipment, thermal insulation of furnace. Different service life and performance unit weight of glass wool is lower than that of rock wool, and add thermosetting resin adhesive, go through pressurized high temperature setting to create a variety of shapes, iron ore, felt, dolomite, are melted in high temperature. Rock wool board, pipe, gabbro, sound absorption. 1. 3, pipe, pipe products. Rock wool is made by natural rocks such as basalt, which can be used for construction and industrial equipment, glass wool insulation material are based on products like quartz sand, belt. The processed fiber, sodium silicate, tough fiber, bauxite as the main raw material, inorganic fiber, , rock wool pipe and feldspar made of fibrosis

- Q: What's the difference between rock wool board, glass wool board, glass wool felt?

- 1, The main difference between rock wool and glass wool lies in withstanding temperature. Rock wool can withstand 650 degrees, but glass wool can withstand 300 degrees. Rock wool board can be used for building external wall thermal insulation, large petrifaction pipelines or tank thermal insulation, etc. Glass wool board is used for tanks at room temperature and piping insulation. Glass wool felt is used in middle of double steel roof. 2, Products in Hebei are mineral wool which is poor and not suitable for exporting, or you will lose worsely. 3,All are fireproof. 4, These materials are fiber products which are water funk. Add water repellent to form waterproof membrane on the fiber surface. Fiber can only absorb no water. It is impossible for fiber to be waterproof as it has many gaps. 5, Aluminum foil can be attached. Glass wool felt can be to be vacuumized to reduce the package volume and transportation cost.

Send your message to us

Glass Wool Pipe Insulation - Good Quality Glass Wool Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords