Aluminum Foil Flowers - Aluminum Coil & Wholesale Aluminum Products

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Applications of Aluminum Foil, Aluminum Coil, Aluminum Products Wholesale:

1.Definition: The hot rolled steel sheet with raised pattern on surface. The raised pattern could be shaped as rhombus,bean or pea. There is not only one kind of pattern on the checkered steel sheet, but also a complex of two or more than two kinds of pattern on surface of one checkered steel sheet. It also could be called as grid steel sheet.

2.Character: The Hot Rolled Checkered Steel Plate possesses a variet of advantages, such as beauty in appearance,skip resistance and saving steel material.Generally speaking,in order to test the mechanical property or the quality of hot rolled checkered steel sheet, the shaping rate and the pattern height should be tested primarily.

3. In conclusion, the hot rolled checkered steel plate can usually be used in the industry of ship-building,boiler,automobil,tractor,train- building and architecture. In details, there are many demands for hot rolled checkered steel plate to make floor,ladder at workshop,work frame pedal,ship deck,car floor and so on.

Package & Delivery of Aluminum Foil, Aluminum Coil, Aluminum Products Wholesale:

1. The items to be prepared for packing include: narrow steel strip, crude steel belt or edge angle steel, kraft paper or galvanized sheet.

2. The hot rolled checkered steel plate should be wrapped with kraft paper or galvanized sheet ouside, and it should be bundled with narrow steel strip, three or two narrow steel strip in longitudinal direction,and the other three or two strips in transverse direction. Furthermore, in order to fix the hot rolled checkered steel plate and avoid the strip at edge shall be broken, the crude steel belt cut into square should be put under the narrow steel strip on the edge. Of course, the hot rolled checkered steel plate could be bundled without kraft paper or galvanized sheet. It depends on customer’s requirement.

3. In consideration of the transportaion from mill to loading port, the truck will be usually used. And the maximum quantity for each truck is 40mt.

4. All in all, we could do in accordance with customer's request.

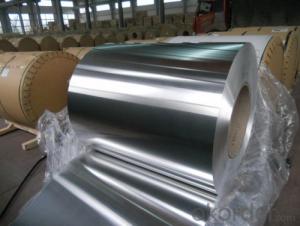

| Aluminum Coil | ||||

| Alloy No. | Thickness (mm) | Width (mm) | Temper | |

| A1050,A1060, A1070,A1100,A1235,A1245 | 0.2-3.0 | 20-1900 | O,H12,H22,H14,H24,H16,H26,H18 | |

| 4.0-12.0 | 1000-1900 | H111,H112 | ||

| A3003,A3004,A3105 | 0.2-4.0 | 20-1900 | O,H12,H22,H14,H24,H16,H26,H18 | |

| 4.0-12.0 | 1000-1900 | H111,H112 | ||

| A5052,A5083,A5754,A5005 | 0.2-4.0 | 20-1900 | O,H12,H22,H14,H24,H16,H26,H18 | |

| 4.0-12.0 | 1000-1900 | H111,H112 | ||

| A6061,A6082,A6063 | 0.8-3.0 | 20-1900 | O | |

| A8011,A1145,A1235 | 0.005-0.2 | 20-1700 | O,,H18,H24 | |

| ID | 76mm,152mm,200mm,300mm,505mm | |||

| Packing : Export wooden pallets, wooden case | ||||

| Standards:ASTM-B209. EN573-1, GB/T3880.1-2006 | ||||

| Quality of material: totally free from defects like white rust, oil patches, roll marks, edge damage, camber, dents, holes, break lines, scratches and free from coil set | ||||

| Application : Mainly used insigns, billboards, building exterior decoration, bus body, high-rise buildings and factories wall decoration, kitchen sink, lamp, fan leaves, with pieces of electronic, chemical equipment, sheet metal processing parts, deep drawing or spinning hollowware, welding parts, heat exchangers, bell surface and disk, plate, kitchenware, decorations, reflective devices, ect | ||||

| MOQ | 2.5 tons | |||

| Payment term: | TT,L/C | |||

| Delivery Time | 15 days after 30% TT payment or receiving L/C copy | |||

| Kind attention : Specifications can be customized as the customer’s requirements. | ||||

Production Flow of Aluminum Foil, Aluminum Coil, Aluminum Products Wholesale:

1.The steel raw materials are first melted in an electric furnace. They are subjected to at least 12 hours of intense heat.

2.The mixture is cast into either large rectangular blooms, slabs or bar-like billets, before taking on a semisolid form.

This initial form of steel is then processed via forming operations that include hot rolling into bars, wires, plates and slabs.

3.The steel is subjected to annealing. This is a heat treatment in which the metal is first heated and then cooled under extreme, controlled conditions. The metal is thus treated for internal stresses and is duly softened and strengthened. This processing is also referred to as 'age hardening'. It requires careful monitoring of temperature and heating and cooling times. The aging temperature affects metal properties massively; while lower temperatures cause high strength and low fracture toughness (i.e., more brittle than ductile), higher temperatures result in a tougher material of lower strength (i.e., more ductile than brittle). Rapid cooling can produce a tough steel with no significant loss in strength. The heat treatment given to stainless steel depends on the type and grade of steel being produced.

4. Annealing or the heat treatment can lead to the development of a precipitate, known as scale. The scale can be removed via several methods, such as pickling, (nitric-hydrofluoric acid bath),electrocleaning(application of an electric current, using phosphoric acid and a cathode), etc.

5. Descaling of the material is introduced into the manufacturing process at different times, depending on the type of steel being produced. While the bar and wire forms have to be additionally treated with hot rolling,forging and extruding, the sheet and strip forms go through annealing after hot rolling.

6. Cutting operations in the manufacturing process are essential in obtaining the desired shape and size of the end product. Mechanical cutting involves the use of guillotine knives and high-speed steel blades for blanking (punching out the shape by shearing) and nibbling (cutting out a series of overlapping holes). It is also cut via flame cutting, a process that involves the use of a flame generated by oxygen, propane and iron powder. The plasma jet cutting method uses an ionized gas column to melt and cut the metal.

6. Manufacturing end products involve further shaping via heat-rolling, pressing, forging and extrusion. The material is then joined via welding and given the desired shape.

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q: I want to try to bake some cookies ( sugar cookie ), but then I don't have wax paperSo i want to ask, is it okay if i use a metal tray, and then i put a layer of aluminium foil with coating a thin layer of butter or vegetable oil, and place my cookies?? pls reply now thanks!

- Yes you canOr, as the other people said, you can bake them on the sheet pan without foilHowever, the foil makes clean up a lot easierAnother option would be to buy a silicon baking mat, called a silpat matJust lay the mat on a sheet pan and bake your cookies on the matThese mats are great and you don't need to oil themThey are reusable, cheap and make clean up a snapthe cookies never stick to themThey are a good option for parchment paper or wax paperand they have multiple uses(By the way, I've used foil many times to bake cookies and it works greatWhy the thumbs down?)

- Q: Okay, just a question - take a traditional parmigiano reggiano cheeseIt's been aged for something like 2 yearsSo why when I buy it does it go bad within a few weeks? Just never made any sense to me.

- I've not had my cheese go bad are you speaking of mold or hardening? improper storage is the problem you should wrap it back up in plastic wrap or foil not just leave it in the original plastic wrapper exposed to air and the drying effects of the refrigerator

- Q: is aluminum foil a pure substance?

- describe the situation that you think you will encounter first( should post this question on 'Bears' site)

- Q: okay first off, i know inhaling weed or anything else is dangerouswhy i dont do itbut my friend doeshe made a pipe out of like copper fittings for plumbing purposes and such (looks pretty neat) and then used like alluminum or tin bowl for the weed, i dont think this is safe because wont the burning of the copper and tin/alluminum is dangerous? could it kill him? is it safe? i asked him not to use it until i found out.

- I know a lot of my friends in high school made one hitters with foiland they're not deadI don't know how safe/unsafe it wasI would say google itIt's pretty common so you should find lots of info :)

- Q: so i can fill it later with Goya custard and then chill it? I heard you can put aluminum foil in the shell and weigh it down with uncooked beans so the dough will keep a shapeIs that the best way?

- This Site Might Help YouRE: how do you draw the energy level diagram for aluminum?

- Q: I want to make a couple of corsets, not super hardcore waist reducing corsets but something that will keep it's shape pretty nicelymy problem is I don't have money or equipment for the steel boning but I was wondering if 1/8quot; aluminum beading wire would be a nice substituteIt seems good to me but I don't really know about good boningThanks in advance for any advice!

- No, it isn't possible to use a aluminum wireThe corset boning have to be flexiblePlastic bones are cheap but they don't hold the shape of corsetYou have only one possibility to buy the spiral or flat steel boning and the steel buskLook on the link below for the Corset Making SuppliesOr try keywords in google to look up suppliers in your country.

- Q: I think it would make the perfect vacation package to pop up and down the east or west coastor tour the gulf for that matter.

- i think it has to do with alloys and ore.

- Q: What's an easy chocalate fudge recipe??

- It is very important to carefully prepare and cook your turkey, because raw and undercooked turkey can have germs, such as salmonella, which can make people sickThat's why you must thoroughly wash and correctly cook your turkey Thoroughly wash everything that the raw turkey and its juices have touchedThat includes all the utensils, cutting boards and counter tops Then, wash your hands very well with warm water and soap, and dry with paper towels, so the germs from the turkey won't get on any other food or surface that you touchCook the turkey to 165? F to be sure all bacteria are killedPut an accurate meat thermometer into the thickest part of the turkey to test for doneness(Many people prefer turkey cooked to higher temperatures for taste and texture.) Dressing: If you are serving dressing with the turkey, we recommend that it be cooked in a separate panIf you do choose to cook the dressing inside the turkey be certain both the turkey and dressing have reached 165? F or above All leftovers need to be refrigerated within two hours after the mealBreak the leftover turkey into small pieces, put them into a shallow pan, and refrigerate, uncovered, until it is coolWhen they are completely cool, cover them For the best quality of leftover turkey, keep it in the refrigerator for only 3 to 4 daysDressing and gravy quality changes after 2 daysReheat gravy to a rolling boil (165? F) before serving again

- Q: Non-destructively, that isI already thought of fuming sulfuric acid and 12M hydrochloric acidI don't think aluminum would like those treatments though.Thanks in advance!

- Don't do itExposed foam is a fire hazard, and as an insulation, it's far more expensiveI bet drywall is more sound-deadening, too, just because it's more denseI'm not sure I can see any potential positives to this proposed project, and I'm sure it violates safety standards and building codes.

Send your message to us

Aluminum Foil Flowers - Aluminum Coil & Wholesale Aluminum Products

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords