Aluminum Foil Facing Insulation for Roofing and Walls

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Aluminum Foil Facing

Aluminum Foil Facing is a kind of film, which is made of by the aluminum foil, fiberglass scrim and Kraft paper. Someone is made of by aluminum and PE woven fabric cloth.

Application of Aluminum Foil Facing

Our aluminum foil facing are mainly used as facing for glass wool insulation, rockwool ,mineral wool etc. Also aluminum foil facing is used under roof decking, under attic rafters, over existing attic thermal insulation, in floors, walls and crawl spaces, and in industrial and commercial buildings to block radiant heat coming into house through the roof during the summer and retain indoor heat generated during in winter.

Advantage of Aluminum Foil Facing

Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly, no smell and not-toxic;

• Smooth and clear surface;

Packing of Aluminum Foil Facing

1. Waterproof paper then PVC shrinking Film

2. Kraft paper only

3. Woven cloth

4. Kraft paper or Water Proof Film then Metal/wooden pallet

5. (Also as your request. )

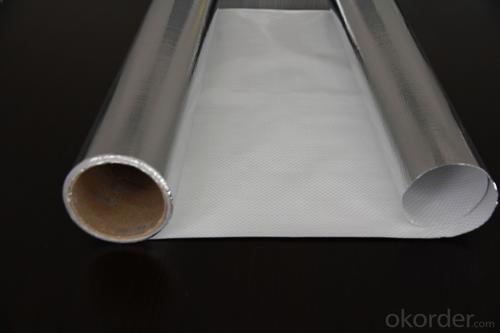

Pictures of Aluminum Foil Facing

Specification of Aluminum Foil Facing

CONSTRUCTION:

Aluminum foil: 7 microns

Tri-way fiberglass scrim: M.D: 8/100mm; X.D: 12/100mm

Adhesive: Polyethylene

Kraft paper: 50gsm (Natural)

TYPICAL PHYSICAL PROPERTIES:

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 88 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 110 50 | ASTM D828 |

Burst strength | N | 30 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C 66°C | No Delamination No Delamination | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Remarks:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and kept from wet and heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of Aluminum Foil Facing and is one of the large-scale professional investment Aluminum Foil Facing bases in China. Annually more than 1000 containers of Aluminum Foil Facing are exported to markets in Europe, America and Japan.

2. What is the storage condition?

The Aluminum Foil Facing should be stored at room temperature and kept from wet and heat source.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Is it possible to use aluminum foil with a reflective side to cover leftover food?

- <p>Yes, aluminum foil facing can be used to wrap leftovers. The reflective side of aluminum foil is often used for its heat-reflective properties in cooking, but it is also suitable for wrapping and storing leftovers. It provides a barrier to air, helping to keep food fresh and preventing freezer burn if used in the freezer. However, it's important to ensure that the foil is tightly sealed around the food to maintain its freshness and prevent contamination.</p>

- Q: This question asks for instructions on how to use aluminum foil as a wrapping material for food.

- <p>To use aluminum foil facing to wrap food, first ensure the foil is clean and free of tears. Cut a piece of foil large enough to fully cover the food item. Place the food in the center of the foil. Bring up the sides of the foil and fold them over the food, sealing the edges tightly to prevent air and moisture from entering. For more secure wrapping, double fold the edges or use a crimping technique. For items like fish or meat, you can also create a sealed pouch by folding the foil over the food, then folding the edges inward and crimping to close. Always handle food with clean hands or utensils to maintain hygiene.</p>

- Q: Is it possible to create a pie crust using aluminum foil as a substitute for traditional pie crust materials?

- <p>No, you cannot use aluminum foil to make a pie crust. A pie crust is traditionally made from flour, butter, and water, which when combined and baked, create a flaky, edible crust. Aluminum foil is a metal material not meant for consumption and lacks the properties needed to form a pie crust. It does not have the ability to be rolled out, shaped, or baked into a flaky, edible form. Instead, it's used for wrapping food to retain moisture or for cooking on a grill.</p>

- Q: Is it safe to use aluminum foil as a cooking surface? If yes, what kinds of foods are suitable for cooking with aluminum foil?

- <p>Yes, aluminum foil can be used for cooking, but it's important to use it safely. It's suitable for wrapping foods like fish, meats, and vegetables to retain moisture and flavor. It's also used for making packets for steaming or baking, and for lining baking sheets to prevent sticking. However, avoid using it with acidic foods or at high temperatures as it can react with the food or release aluminum into the food. Always use heavy-duty aluminum foil for cooking to ensure it can withstand the heat.</p>

- Q: The user is asking if it's possible to use aluminum foil with a reflective side facing out to cook a roast chicken.

- <p>Yes, you can use aluminum foil facing to make a roast chicken. The reflective side of the aluminum foil can help to retain heat and cook the chicken more evenly. However, it's important to note that the foil should not be in direct contact with the heat source for an extended period as it may cause the foil to melt or create a fire hazard. Make sure to monitor the cooking process and adjust the foil placement as needed to prevent any safety issues.</p>

- Q: What are the primary applications or purposes of aluminum foil facing in various industries or everyday life?

- <p>Aluminum foil facing is primarily used for its heat reflective properties, making it ideal for insulation in construction and roofing. It also serves as a moisture barrier and vapor barrier in walls and ceilings, helping to prevent mold and mildew. In the HVAC industry, it's used for duct insulation, enhancing energy efficiency. Additionally, it's utilized in packaging for food and pharmaceuticals to protect contents from light, air, and moisture, thus preserving freshness and quality.</p>

- Q: Is it possible to recycle aluminum foil facing multiple times? If yes, what is the process involved?

- <p>Yes, aluminum foil facing can be recycled multiple times. The recycling process involves collecting and sorting aluminum waste, which is then shredded or crushed. The material is melted in a furnace at high temperatures, and the molten aluminum is poured into molds to form new products. This process can be repeated indefinitely without losing the quality of the aluminum, making it one of the most recycled materials globally. The recycling of aluminum saves energy and reduces the environmental impact compared to producing aluminum from raw materials.</p>

- Q: The user is asking for alternative uses of aluminum foil facing, beyond its common applications.

- <p>Absolutely! Aluminum foil facing has several unexpected uses. It can be used to clean stubborn grime and rust from cookware and tools. It's also great for creating a reflective surface to direct sunlight for better indoor lighting or to speed up the thawing of frozen items. In gardening, it can deter pests and reflect heat to warm your plants. Additionally, it can be used to sharpen scissors or knives by cutting through it multiple times, and it can even be used as a fire starter in camping situations. These are just a few creative ways to use aluminum foil facing beyond its typical applications.</p>

- Q: This question asks for a list of various types of aluminum foil facing that can be found in the market.

- <p>There are several types of aluminum foil facing available in the market today, including: 1. Standard Aluminum Foil Facing, which is the most common type used for insulation and moisture protection. 2. Reinforced Aluminum Foil Facing, which is stronger and more durable, often used in high-temperature applications. 3. Embossed Aluminum Foil Facing, which has a textured surface for improved aesthetics and grip. 4. Coated Aluminum Foil Facing, which is coated with materials like polyethylene for added protection against chemicals or moisture. 5. Perforated Aluminum Foil Facing, which has small holes for ventilation or drainage. 6. Laminated Aluminum Foil Facing, which combines aluminum with other materials for enhanced properties. These types cater to various applications in construction, food packaging, and other industries.</p>

- Q: Explain the distinct characteristics of aluminum foil facing compared to other metal facings.

- <p>Aluminum foil facing is a type of metal facing material that is made from thin sheets of aluminum, known for its light weight, high reflectivity, and excellent heat resistance. It is commonly used in construction for insulation and moisture protection. In contrast, other types of metal facings, such as steel or copper, may offer different properties. Steel facings are often stronger and more durable but can be heavier and less resistant to corrosion without protective coatings. Copper facings are known for their natural resistance to corrosion and can be used in applications requiring antimicrobial properties or high thermal and electrical conductivity. Each type of metal facing has its unique advantages and is chosen based on specific application needs.</p>

Send your message to us

Aluminum Foil Facing Insulation for Roofing and Walls

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords