Aluminum Foil Facing HVAC Insulation Tapes - FSK T-S4006P

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 112 m²

- Supply Capability:

- 30000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

T-S4001PFR Aluminum Foil Tape

Flame retardant aluminum foil tapes

Production Description

T-F3604FR Aluminum Foil Tape is a 36u nominal dead soft aluminum foil with aggressive solvent acrylic adhesive and protected by easy release liner.

Features

¨ Excellent Peel Adhesion ¨ Good Initial Tack & Permanent Bonding

¨ Good Water & Fire Resistance ¨ Outstanding Temperature & Aging Resistance

Applications

Super performance, professional grade 36u aluminum foil tape. Ideal for sealing joints / seams against moisture and vapor on foil jacketing insulation. Suitable for many other permanent sealing, holding, splicing or masking applications requiring the protection offered by a foil backing

Technical Data Sheet

Property | Unit | Value | Test Method |

Backing Thickness | Micron | 40 | PSTC-33 / ASTM D3652 |

Peel Adhesion | N/25mm | 20 | PSTC-1 / ASTM D3330 |

Tack Rolling Ball | cm | 20 | PSTC-6 / ASTM D3121 |

Tensile Strength | N/25mm | 50 | PSTC-31 / ASTM D3759 |

Elongation | % | 3.0 | PSTC-31 / ASTM D3759 |

Service Temperature | °C | -30 ~ +120 | ---------- |

Applying Temperature | °C | +10 ~ +40 | ---------- |

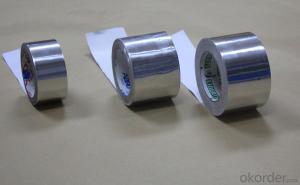

Cut Roll: 48mm, 50mm (2"), 60mm, 63mm (2.5"), 72mm, 75mm (3"), 96mm, 100mm (4").

Jumbo Roll: 1200mm x 1350M, 1200mm x 1200M.

Remarks:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm; Length: Cut Roll: ±0.3m, Jumbo Roll ±0.5%.

3. The product should be stored at room temperature and kept from wet and heat source.

Shelf life: One year from shipment date when stored at 21°C (70°F) / 50% relative humidity out of direct sunlight.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

- Q: What distinguishes various grades of aluminum foil sheets from one another?

- <p>Different grades of aluminum foil sheets are distinguished by their thickness, strength, and purity. Grade 1 is the purest and softest, used for food wrapping and baking. Grade 2 is harder and more tear-resistant, suitable for heavy-duty use like grilling. Grade 3 is an alloy and offers high strength and durability, often used in industrial applications. Grade 4 is a heat-treatable alloy, providing high strength and used in aerospace and automotive industries. Each grade has specific applications based on its unique properties.</p>

- Q: Is it safe to use aluminum foil facing to wrap food for cooking methods like roasting or grilling?

- <p>Yes, you can use aluminum foil facing to wrap food before roasting or grilling. Aluminum foil is a common and safe material used in cooking, especially for wrapping foods to retain moisture and flavor. It's important to ensure the foil is food-grade and not damaged, as this can affect the food's safety and taste. When using foil, make sure it's sealed properly to prevent juices from leaking and to keep the food moist. Avoid direct contact with the heat source as much as possible to prevent the foil from burning and potentially releasing any harmful substances into the food.</p>

- Q: Is it possible to create a pie crust using aluminum foil as a substitute for traditional pie crust materials?

- <p>No, you cannot use aluminum foil to make a pie crust. A pie crust is traditionally made from flour, butter, and water, which when combined and baked, create a flaky, edible crust. Aluminum foil is a metal material not meant for consumption and lacks the properties needed to form a pie crust. It does not have the ability to be rolled out, shaped, or baked into a flaky, edible form. Instead, it's used for wrapping food to retain moisture or for cooking on a grill.</p>

- Q: How should aluminum foil be stored after it has been used for cooking or food storage to keep it clean and ready for future use?

- <p>The best ways to store aluminum foil facing after using it for cooking or food storage involve cleaning and organizing it properly. First, wash the used foil with warm soapy water to remove any food residue. Rinse it thoroughly and pat dry with a clean towel. To store, roll the foil tightly starting from the center, keeping it compact and neat. Alternatively, you can store it in a resealable plastic bag or a dedicated foil container to keep it clean and prevent it from tearing. Always store it in a cool, dry place away from direct sunlight to maintain its quality.</p>

- Q: Describe the optimal method for utilizing aluminum foil facing in cooking.

- <p>The best way to use aluminum foil facing for cooking is to preheat your oven and ensure the foil is shiny side up to reflect heat. For baking, create a tent with the foil to protect delicate foods from direct heat, which can prevent burning. When roasting, use foil to wrap foods like fish or vegetables to steam them, enhancing flavor and moisture retention. For grilling, use foil to create packets to cook foods indirectly or to line the grill to prevent food from sticking. Always handle with care to avoid tearing and ensure even heat distribution.</p>

- Q: Can aluminum foil be used as a material for crafting a pot holder or pot lid holder?

- <p>While aluminum foil is heat resistant to a certain extent, it is not recommended for making a pot holder or pot lid holder due to its low melting point and potential to conduct heat, which could lead to burns or damage to the foil. Instead, consider materials designed for heat resistance such as silicone, fabric with heat-resistant properties, or insulated materials specifically made for kitchen use. These materials are safer and more effective for handling hot pots and lids.</p>

- Q: Is it safe to use old aluminum foil for food packaging, considering potential health risks and material degradation?

- <p>Using old aluminum foil for food packaging is not recommended. Over time, aluminum foil can become discolored, thin, or develop pinholes, which can compromise its integrity. These changes can lead to food contamination and the foil's ability to protect food from bacteria or other contaminants. Additionally, old aluminum foil may contain residues from previous uses that could mix with new food items, potentially causing off-flavors or health concerns. It's best to use fresh, clean aluminum foil for food packaging to ensure safety and hygiene.</p>

- Q: Is it possible to use aluminum foil with a reflective side to cook pizzas or grilled cheese sandwiches?

- <p>Yes, you can use aluminum foil facing to make pizzas or grilled cheese sandwiches. The reflective side of the foil can help distribute heat evenly, which is beneficial for cooking these items evenly. However, it's important to ensure that the foil does not come into direct contact with the heating element of your oven, as it can cause a fire hazard. Always follow safety guidelines and adjust the cooking time and temperature as needed to prevent burning or melting the foil.</p>

- Q: Explain the distinctions among various types of aluminum foil facing materials.

- <p>Aluminum foil facing can be categorized into several types based on their composition and application. Type 1 is plain aluminum foil, commonly used for food packaging and general wrapping. Type 2 is aluminum foil laminated with plastic, which offers better barrier properties and is used in flexible packaging. Type 3 is aluminum foil laminated with Kraft paper, providing a sturdier material for packaging and insulation. Type 4 is aluminum foil laminated with polyethylene, which is waterproof and used for construction and insulation. Each type has unique properties, such as barrier resistance, strength, and heat resistance, making them suitable for different applications.</p>

- Q: Is it possible to recycle aluminum foil with a facing layer? If yes, what is the process involved?

- <p>Yes, aluminum foil facing can be recycled. The process typically involves separating the aluminum from the facing material. This is done by specialized recycling facilities that use methods such as shredding, washing, and magnetic separation to remove impurities. The aluminum is then melted down and repurposed into new products. It's important to check local recycling guidelines, as some facilities may not accept foil with a facing layer due to the difficulty in separation or the presence of non-recyclable components.</p>

Send your message to us

Aluminum Foil Facing HVAC Insulation Tapes - FSK T-S4006P

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 112 m²

- Supply Capability:

- 30000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords