Aluminum Foil Facing Glass Wool Insulation for Ceilings, Panels, and Roofing

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Aluminum Foil Facing

Aluminum Foil Facing is a kind of film, which is made of by the aluminum foil, fiberglass scrim and Kraft paper. Someone is made of by aluminum and PE woven fabric cloth.

Application of Aluminum Foil Facing

Our aluminum foil facing are mainly used as facing for glass wool insulation, rockwool, mineral wool etc. Also aluminum foil facing is used under roof decking, under attic rafters, over existing attic thermal insulation, in floors, walls and crawl spaces, and in industrial and commercial buildings to block radiant heat coming into house through the roof during the summer and retain indoor heat generated during in winter

Advantage of Aluminum Foil Facing

Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly, no smell and not-toxic;

• Smooth and clear surface;

Packing of Aluminum Foil Facing

1. Waterproof paper then PVC shrinking Film

2. Kraft paper only

3. Woven cloth

4. Kraft paper or Water Proof Film then Metal/wooden pallet

5. (Also as your request. )

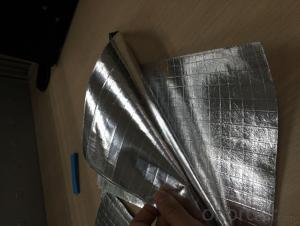

Pictures of Aluminum Foil Facing

Specification of Aluminum Foil Facing

COMPOSITION:

Aluminum foil: 7 microns

Adhesive: Polyethylene

Kraft paper: 50gsm (Natural)

TYPICAL PHYSICAL PROPERTIES:

PROPERTIES | UNIT | VALUE | TEST METHOD | |||||

Basic weight | gsm | 80 | ASTM D646 | |||||

Tensile strength: M. D. X. D. | N/25mm | 95 50 | ASTM C1136 | |||||

Burst strength | N | 25 | ASTM D774 | |||||

Reflectivity of foil surface | % | 95 | ---------- | |||||

Remarks:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and kept from wet and heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of Aluminum Foil Facing and is one of the large-scale professional investment Aluminum Foil Facing bases in China. Annually more than 1000 containers of Aluminum Foil Facing are exported to markets in Europe, America and Japan.

2. What is the storage condition?

The Aluminum Foil Facing should be stored at room temperature and kept from wet and heat source.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: This question asks for clarification on the distinction between two types of aluminum products: aluminum foil facing and aluminum foil sheet.

- <p>Aluminum foil facing is a thin layer of aluminum laminated to a substrate, typically used in construction for insulation and moisture barrier purposes. It provides a reflective surface that can enhance energy efficiency by reflecting heat. On the other hand, aluminum foil sheet is a flat, flexible material made of pure aluminum or aluminum alloy, commonly used in cooking, food packaging, and crafts. It is not bonded to any other material and is available in various thicknesses and widths. The primary difference lies in their applications and composition; foil facing is part of a composite material for construction, while foil sheets are standalone materials for a variety of uses.</p>

- Q: Is it possible for metal shavings to contaminate food when using aluminum foil with a shiny side?

- <p>There is minimal risk of metal shavings getting into food when using aluminum foil facing. Aluminum foil is designed to be safe for food contact and is generally resistant to shedding particles. However, if the foil is damaged or handled roughly, small particles could potentially come off. To mitigate this risk, ensure the foil is in good condition, avoid tearing it, and handle it carefully to prevent any metal contamination.</p>

- Q: Is it safe to use aluminum foil facing to wrap food for cooking methods like roasting or grilling?

- <p>Yes, you can use aluminum foil facing to wrap food before roasting or grilling. Aluminum foil is a common and safe material used in cooking, especially for wrapping foods to retain moisture and flavor. It's important to ensure the foil is food-grade and not damaged, as this can affect the food's safety and taste. When using foil, make sure it's sealed properly to prevent juices from leaking and to keep the food moist. Avoid direct contact with the heat source as much as possible to prevent the foil from burning and potentially releasing any harmful substances into the food.</p>

- Q: This question asks for a comparison of the differences among different types of plastic containers.

- <p>Plastic containers vary in material composition, durability, temperature resistance, and intended use. HDPE (High-Density Polyethylene) is sturdy and good for detergent bottles and milk jugs. LDPE (Low-Density Polyethylene) is flexible and used for plastic bags and film. PET (Polyethylene Terephthalate) is recyclable and used for water bottles and food containers. PVC (Polyvinyl Chloride) is durable but not food-safe due to potential leaching of harmful chemicals. Polypropylene is resistant to heat and acids, making it suitable for microwave-safe containers. Polystyrene is lightweight and clear but not microwave-safe and can release styrene, a harmful chemical, when heated. Each type has specific uses and properties that make it suitable or unsuitable for certain applications.</p>

- Q: Is it safe to use aluminum foil as a liner in a slow cooker, and are there any potential risks or benefits?

- <p>Using aluminum foil as a facing in a slow cooker is generally safe. It can help with easy cleanup and may distribute heat evenly. However, it's important to ensure that the foil doesn't touch the heating element, as this can cause damage to both the foil and the slow cooker. Additionally, while aluminum foil is non-toxic and generally safe, there are concerns about potential leaching of aluminum into food, especially with acidic foods. For health-conscious individuals, using a slow cooker liner made from materials like silicone or stainless steel might be a better alternative.</p>

- Q: What are the most suitable materials for creating aluminum foil facing?

- <p>The best materials for making aluminum foil facing are typically aluminum alloys, specifically 1100, 3003, or 8011 series alloys. These alloys offer excellent formability, corrosion resistance, and reflectivity, which are crucial for applications like insulation, construction, and heat management. Additionally, the facing material often includes a layer of polyester or polyethylene film to enhance durability and prevent tearing. The choice of material can also depend on specific requirements such as temperature resistance, UV resistance, and environmental conditions.</p>

- Q: This question asks for the optimal methods of preserving leftover food using aluminum foil.

- <p>The best ways to store leftovers using aluminum foil involve ensuring the food is cool before wrapping, covering the entire dish tightly, and sealing the foil properly. First, let the leftovers cool down to room temperature to prevent condensation. Then, wrap the dish completely with aluminum foil, making sure to cover the edges and corners to avoid air exposure. For added protection, you can double-wrap the dish. Seal the foil by pressing the edges together firmly. Store the wrapped leftovers in the refrigerator or freezer, depending on how soon you plan to consume them.</p>

- Q: What are the potential health risks associated with the use of aluminum foil facing?

- <p>There are no significant health risks associated with the use of aluminum foil facing in everyday cooking and food storage. While aluminum is a common element and can be found naturally in many foods and water sources, the amount that might leach from foil into food is minimal and not considered harmful. However, it's always best to avoid wrapping acidic or highly salty foods in aluminum foil, as this might increase the potential for aluminum to leach into the food. For most people, the small amounts of aluminum that could come into contact with food from foil are not a health concern.</p>

- Q: The user is asking if it's possible to use aluminum foil with a shiny side facing outward to create a sandwich roll.

- <p>Yes, you can use aluminum foil to make a sandwich roll, but it's not recommended to use the shiny side facing outward. The dull side of the foil is typically used for food contact because it's less likely to transfer any potential residues or chemicals to the food. The shiny side may have a coating that isn't safe for direct food contact. Always ensure that the foil is food-safe and use it according to the manufacturer's instructions.</p>

- Q: Does using aluminum foil facing have any positive effects on health when baking bread?

- <p>Using aluminum foil facing when baking bread does not directly provide health benefits. However, it can help in achieving a more even bake and a better crust, which may enhance the overall quality of the bread. Aluminum foil facing can also prevent bread from burning by reflecting heat away from the bread's surface. While this doesn't impact health, it can improve the bread's taste and texture, which might indirectly contribute to a more enjoyable eating experience and potentially encourage healthier food choices.</p>

Send your message to us

Aluminum Foil Facing Glass Wool Insulation for Ceilings, Panels, and Roofing

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords