Aluminum Foil Facing FSK Insulation Facing for Glasswool and Rockwool Seal Lamination

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

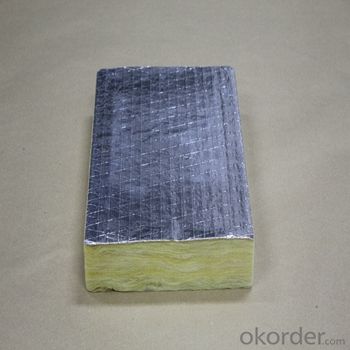

1. Aluminum Foil Facing Description:

The production technologies and products performance of aluminum foil facing have been up to international advanced level. Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination Glasswool.

2.Main Features of the Aluminum foil facing:

• Light weight

• Small inertia resistance

• High manufacturing accuracy

• Strong heat dissipation ability

• Good visual effect

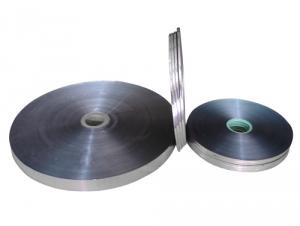

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

(1) How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

- Q: What are the alternatives to using aluminum foil facing in various applications?

- <p>Yes, there are several substitutes for aluminum foil facing. These include: 1) Heavy-duty aluminum foil, which can be used for a more durable barrier. 2) Parchment paper, which is great for baking and resists tearing. 3) Silicone baking mats, reusable and non-stick. 4) Wax paper, useful for wrapping and storage but not for high heat. 5) Plastic wrap, suitable for food storage but not for cooking. 6) Tin foil, a cheaper alternative but less heat resistant. Always consider the specific needs of your application when choosing a substitute.</p>

- Q: Is it possible to use aluminum foil with a reflective side for food freezing purposes?

- <p>Yes, aluminum foil facing can be used for freezing food. It helps to maintain the temperature and prevent freezer burn by acting as a barrier to air and moisture. However, it's important to ensure that the foil is food-grade and does not have any sharp edges that could puncture the food packaging. Additionally, it's recommended to wrap the food securely in the foil to minimize air exposure and maximize the preservation of the food's quality and taste.</p>

- Q: Can aluminum foil be utilized as a facing material for cooking in a microwave oven?

- <p>Aluminum foil facing should not be used for microwave cooking. Microwaves can cause the foil to heat up and potentially create sparks or even start a fire. It can also reflect microwaves, damaging the microwave's interior and potentially the oven itself. Always use microwave-safe materials, such as glass or microwave-safe plastic containers, for cooking in a microwave.</p>

- Q: Is it safe to use aluminum foil as a cooking surface? If yes, what kinds of foods are suitable for cooking with aluminum foil?

- <p>Yes, aluminum foil can be used for cooking, but it's important to use it safely. It's suitable for wrapping foods like fish, meats, and vegetables to retain moisture and flavor. It's also used for making packets for steaming or baking, and for lining baking sheets to prevent sticking. However, avoid using it with acidic foods or at high temperatures as it can react with the food or release aluminum into the food. Always use heavy-duty aluminum foil for cooking to ensure it can withstand the heat.</p>

- Q: What are the potential health risks associated with cooking food using aluminum foil?

- <p>Cooking with aluminum foil can potentially lead to the leaching of aluminum into the food, which may have health implications. While the body naturally eliminates small amounts of aluminum, excessive intake can be harmful. Aluminum has been linked to neurological disorders, including Alzheimer's disease, although the connection is not definitively proven. It's also important to note that the amount of aluminum that leaches into food during cooking is generally considered to be low. However, for those concerned about aluminum exposure, it's advisable to minimize the use of aluminum foil in cooking, especially for acidic foods which can increase the rate of aluminum leaching.</p>

- Q: Can aluminum foil be used as a material for crafting a pot holder or pot lid holder?

- <p>While aluminum foil is heat resistant to a certain extent, it is not recommended for making a pot holder or pot lid holder due to its low melting point and potential to conduct heat, which could lead to burns or damage to the foil. Instead, consider materials designed for heat resistance such as silicone, fabric with heat-resistant properties, or insulated materials specifically made for kitchen use. These materials are safer and more effective for handling hot pots and lids.</p>

- Q: What precautions can be taken to prevent burns while using aluminum foil in cooking or baking?

- <p>To avoid getting burned when using aluminum foil for cooking or baking, follow these safety tips: Always handle the foil with utensils or wear heat-resistant gloves. Avoid touching the foil directly after cooking or baking, as it can retain heat. Use heavy-duty aluminum foil to prevent punctures and tears that can cause burns. Keep aluminum foil away from open flames or high heat sources to prevent it from catching fire. Always use caution when removing aluminum foil from an oven or stovetop, and let it cool slightly before handling.</p>

- Q: Describe the most effective methods for utilizing aluminum foil in baking processes.

- <p>The best way to use aluminum foil in baking involves lining the baking sheet to prevent food from sticking and to simplify cleanup. Preheat the foil by placing it on the sheet and heating the oven before putting in the food. For even cooking, ensure the foil doesn't touch the heating elements. Use foil to wrap foods like potatoes or fish for steaming, or create packets for en papillote cooking. When using foil to cover food, tent it loosely to allow for air circulation. For browning, remove the foil during the last part of baking. Always handle with care to avoid tearing and ensure椋熷搧瀹夊叏.</p>

- Q: What are the advantages of using recycled aluminum foil facing compared to new aluminum foil facing?

- <p>Using recycled aluminum foil facing is generally better for the environment as it reduces waste and conserves resources. Recycling aluminum uses significantly less energy compared to producing new aluminum from raw materials. However, for applications requiring high performance or purity, new aluminum foil facing might be necessary. In terms of cost, recycled aluminum is often more affordable. It's important to consider the specific needs of your project or product when deciding between recycled and new aluminum foil facing.</p>

- Q: Does using aluminum foil facing have any positive effects on health when baking bread?

- <p>Using aluminum foil facing when baking bread does not directly provide health benefits. However, it can help in achieving a more even bake and a better crust, which may enhance the overall quality of the bread. Aluminum foil facing can also prevent bread from burning by reflecting heat away from the bread's surface. While this doesn't impact health, it can improve the bread's taste and texture, which might indirectly contribute to a more enjoyable eating experience and potentially encourage healthier food choices.</p>

Send your message to us

Aluminum Foil Facing FSK Insulation Facing for Glasswool and Rockwool Seal Lamination

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords