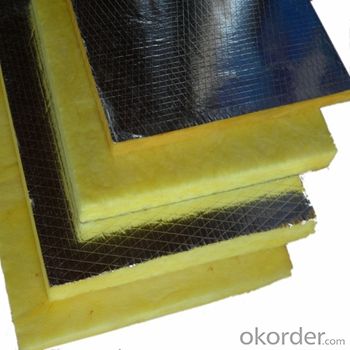

Glass Wool Blanket 10kg/m3 with Aluminum Foil Facing

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Glass Wool Blanket 10kg/m3 With Aluminum Foil Facing

1. Glass Wool Blanket 10kg/m3 With Aluminum Foil Facing Description

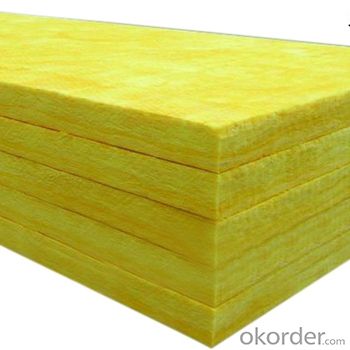

Glasswool board is the unearthly sound absorbing and warm keeping material. It has been widely applied for heat insulation of house wall, compartment; temperature keeping of computer rooms, refrigerator; denoise of power plants and pump rooms; adjustment of Hi-fi etc.

This special cell structure means that the sheet doe’s not conduct heat. When you lay XPS boards as an underlay any heat from your room or floor will be reflected back towards the floor surface. As you will not be wasting heat through your floor you will utilize your energy in an effective manner and thereby lower your energy consumption and carbon footprint.

2. Glass Wool Blanket 10kg/m3 With Aluminum Foil Facing Main Features

1. Excellent thermal insulation

2. High compressive strength of excellence

3. High-quality water-repellent, moisture resistance

4. Energy saving and environmental protection

5. Excellent heat preservation and insulation

3. Glass Wool Blanket 10kg/m3 With Aluminum Foil Facing Images

4. Glass Wool Blanket 10kg/m3 With Aluminum Foil Facing Specification

density(kg/m3) | width(mm) | thickness(mm) | length(m) | packing/roll Vacuum package | |

10-48 | 1200 | 25-150 | 10-30m | 2roll | |

10-48 | 1200 | 25-150 | 10-30m | 1roll | two-roll overlapping |

10-48 | 1200 | 25-150 | 10-30m | 1roll | two-roll overlapping |

10-48 | 1200 | 25-150 | 10-30m | 1roll | two-roll overlapping |

10-48 | 1200 | 25-150 | 10-30m | 1roll | two-roll overlapping |

5. FAQ

(1) How about your company?

A world class manufacturer & supplier of glasswool and is one of the large scale professional investment glasswool bases in China. Annually more than 1000 containers of glasswool are exported to markets in Europe, America and Japan.

(2)What is the storage condition?

The products should be stored at room temperature and kept from wet and heat source.

The user should take test and do trial application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

(3) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

(4) How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served

- Q: Is hyperfine glass fiber cotton different from the centrifugal glass wool?

- They are basically the same.

- Q: Standard for the implementation of glass wool products

- GB / T 13350-2000 "Glass wool and its products for insulation"

- Q: what is the specification of glass wool air duct?

- The long side size of the air duct(round air duct diameter), and the air duct work pressure depands: Low pressure systems: P 500 pa or less medium voltage system: In 500 pa1500pa middle and low pressure,take thickness of the galvanized iron air duct as example: Long side size of air duct b ≤320 mm: 0.5 mm320

- Q: Which thermal insulation materials are the best for air-conditioners? Is it rubber and plastic, PEF or glass wool?

- Copper contains rubber and plastic. PEF and glass wool are both suitable, but glass wool is not recommend for its poor waterproofing performance, you'd better use rubber and plastic! You can select them with appropriate thickness according to your local winter temperature, or else it will be frozen in winter for it is too thin.

- Q: As for glass wool board and rock wool board, which kind of material is better?

- substitutes of rock wool and glass wool, performance index, the glass wool price is relatively high, less manufacturers.

- Q: Can glass wool be used in exterior wall for thermal insulation?

- Glass wool is categorized into glass fiber, which is a manmade inorganic fiber. Glass wool is a material which fibering melting glass to form cottony shape. Its chemical composition belongs to the classification of glass, being an inorganic fiber. So, it is good shaped with small volume density, low thermal conductivity, good thermal insulation and sound absorption properties, great corrosion resistance as well as stable chemical performance. Glass fiber cotton, if used in buildings, its surface always is attached to veneer with somewhat certain acoustic transmission effect, such as of plastic film, metal screen, window screen, fireproof cloth, glass cloth and other materials with less than 0.5mm, basically able to keep the original sound absorption property.

- Q: Whose thermal insulation performance is the best between glass wool felts and cystosepiments?

- personally I believe that foamed concrete thermal insulation boards are better.

- Q: What is the difference between Kun Nai glass?wool?board and rock wool?

- Hastelloy alloy has made remarkable breakthrough in 1960s. Before that corrosion hinders the development need to weld the alloy solution treatment HAZ corrosion resistance can lower the number of devices produced by welding must be applied engineering problems to provide solutions HastelloyC-276 case http://www.jyx66 /

- Q: Does rock wool look like glass wool ?

- They are not the same. The main raw material of glass wool is glass with long thin and elastic cellosilk, while that of rock wool is basalt with short and thick rock wool silk. But both are used for thermal insulation. Glass wool is more expensive.

- Q: What is the construction technology of glass wool felt aluminium expanded sheet sound-absorbent wall?

- 1, Technological process: Dry laying a layer of asphalt felt →install wood keel → install gypsum board → paste glass wool felt → pave and nail a layer of glass fiber cloth → install aluminium expanded sheets → fix aluminium expanded sheets. 2, Operating points of the construction method. a, Embedded anticorrosion wood bricks: During masonry construction, laying bricks while pre-casting anticorrosion wood bricks (40 × 60 × 60), and the horizontal distance is 400 to 500 with the vertical distance of 400.

Send your message to us

Glass Wool Blanket 10kg/m3 with Aluminum Foil Facing

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords