Aluminum Foil Facing AL-PET Laminated Foil Composite for Shielding Coaxial Cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Mylar foil Shielding Foil for Coaxial Cable communication cable

1.Structure of Aluminum Mylar foil Shielding Foil Description:

Electrical cable is used to transfer electricity, information and the realization of electromagnetic energy transformation. The electrical cable in a broad term mainly indicates to cable and in a narrow term indicate insulation material. Its definition is the aggregation of different parts below: one or more insulation cores, the wrapping layers of the cores, the general protective layers and the outer protective layers. Cables also include additive conductor without insulator.

2.Main Features of the Aluminum Mylar foil Shielding Foil:

Aluminum Mylar foil Shielding Foil is applicable to the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

1.Thickness: min 6.5mic; width: 300-1000mm.

2. According to GB/T 3198-2010.

3.Usages: cable shield, candy wrap

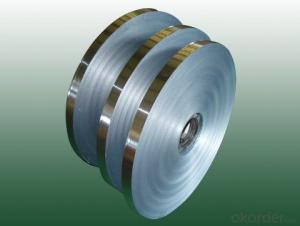

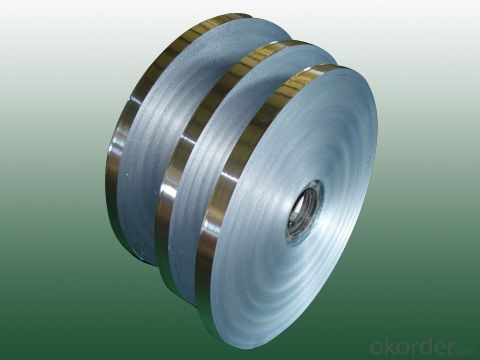

3. Aluminum Mylar foil Shielding Foil Images

4. Aluminum Mylar foil Shielding Foil Specification

AL-PET laminated foil

Description: Apply for overall or individual twisted pair shield for electronic cable and local network cables, protect from external electromagnetic interference. Features option of LUBRITAPE apply to decrease 50% friction of aluminum surface.

Construction: Aluminum foil, Polyester film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

FP007012 | 22±3 | 7 | 3 | 12 | 38.8±5% |

FP010012 | 25±3 | 10 | 3 | 12 | 46.9±5% |

FP020020 | 43±3 | 20 | 3 | 20 | 83.8±5% |

FP025012 | 40±3 | 25 | 3 | 12 | 87.6±5% |

Special specifications are also available, according to customer’s order. | |||||

AL-PET-AL laminated foil

Description: resilient shielding in cable assembling and provide the enhanced shielding required in harsh environments.

Construction: Aluminum foil +Polyester film+ Aluminum foil

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | WEIGHT |

DFP007015 | 35±3 | 7 | 3 | 15 | 3 | 7 | 65±5% |

DFP009020 | 39±4 | 9 | 3 | 15 | 3 | 9 | 76±5% |

DFP015025 | 61±5 | 15 | 3 | 25 | 3 | 15 | 115±5% |

DFP025025 | 80±5 | 25 | 3 | 25 | 3 | 25 | 175±5% |

Special specifications are also available, according to customer’s order. | |||||||

Bonded AL-PET laminated foil

Description: A laminated aluminum-polyester-aluminum tape is fully bonded to the foam dielectric to provide 100% coverage, longitudinally applied over the polyethylene core and the tape minimizes signal leakage.

Construction: Aluminum foil + Polyester film + Aluminum foil + EMAA film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | GLUE | EMAA | WEIGHT |

DFPH009012 | 65±5 | 9 | 3 | 12 | 3 | 9 | 3 | 25 | 98±5% |

DFPH009020 | 72±5 | 9 | 3 | 20 | 3 | 9 | 3 | 25 | 108±5% |

DFPH009025 | 75±5 | 9 | 3 | 25 | 3 | 9 | 3 | 25 | 114±5% |

DFPH010025 | 84±5 | 10 | 3 | 25 | 3 | 10 | 3 | 25 | 126±5% |

Special specifications are also available, according to customer’s order. | |||||||||

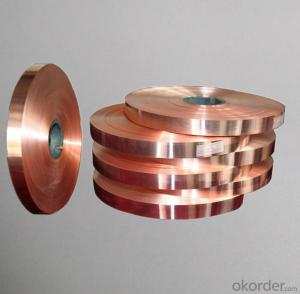

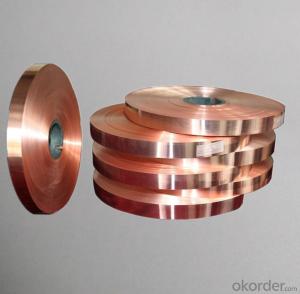

Copper polyester foil

Description: Copper foil, copper lamination foil typically use as shielding for low/medium voltage cable and radio frequency coaxial cable. The rolled annealing copper foil is flexible to wrap cable core, also it has the excellent physical properties, Polyester film provides electrical insulation and high mechanical properties.

Construction: Copper foil + Polyester film

CODE | TOTAL THICKNESS | CU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

CP018012 | 33±3 | 18 | 3 | 12 | 175±10% |

CP007020 | 46±3 | 18 | 3 | 25 | 195±10% |

CP015012 | 30±3 | 15 | 3 | 12 | 160±10% |

Special specifications are also available, according to customer’s order. | |||||

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① Where you used this foil?

Aluminum Mylar foil Shielding Foil is used for cable shield, candy wrap for the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: This question asks for the correct method of storing aluminum foil to keep it from getting tangled or damaged.

- <p>To store aluminum foil facing properly, first ensure that the foil is clean and dry. Roll it tightly starting from the shiny side, which should be facing outward. Secure the roll with a rubber band or a piece of tape. Store the roll in a cool, dry place, away from direct sunlight to prevent damage and to maintain freshness. Some people also use a paper towel tube to help keep the foil roll compact and prevent it from unraveling.</p>

- Q: This question asks for a comparison of the pros and cons of using aluminum foil as a facing material in food packaging.

- <p>Aluminum foil facing in food packaging offers several advantages, such as excellent barrier properties against light, oxygen, and moisture, which helps in preserving the freshness and taste of food. It is also lightweight, cost-effective, and provides a shiny, visually appealing appearance. Additionally, aluminum foil is recyclable, contributing to sustainability efforts. However, there are disadvantages, including its limited heat resistance, which can lead to warping or melting when exposed to high temperatures. It can also cause environmental concerns due to improper disposal, as it is not biodegradable and can contribute to littering if not recycled properly.</p>

- Q: How should aluminum foil be properly stored when not in use to maintain its quality and usability?

- <p>The best ways to store aluminum foil when not in use include keeping it in a cool, dry place away from direct sunlight to prevent degradation. It's advisable to store it in its original box or a resealable plastic container to protect it from moisture and air exposure. Some people also use a paper towel roll as a dispenser by placing the aluminum foil around it, ensuring the shiny side is out for easy access. Keeping it in a drawer is also common, but it's important to prevent it from crumpling or tearing.</p>

- Q: This question asks for methods to prevent food waste when utilizing food covers or containers.

- <p>To avoid food waste with food covers or containers, plan your meals ahead of time and only prepare what you can consume. Use the right size container for the amount of food you have. Store leftovers properly by cooling them down quickly and sealing containers tightly to prevent spoilage. Always check the contents of your containers before shopping to avoid buying duplicates. Use containers with clear labels to easily identify what's inside and its preparation date. Finally, rotate your food storage to use older items first and reduce waste.</p>

- Q: What are the methods to prevent food from sticking to the aluminum foil surface during cooking?

- <p>To prevent food from sticking to the surface of aluminum foil when cooking, you can use a few techniques. First, lightly coat the foil with a thin layer of oil or non-stick cooking spray. This creates a barrier that food won't stick to. Second, ensure that the foil is smooth and wrinkle-free; any rough spots can cause food to stick. Additionally, avoid overfilling the foil as this can lead to uneven cooking and sticking. Finally, consider using parchment paper or a silicone baking mat instead of foil for some foods, as they can provide a non-stick surface without the risk of aluminum foil tearing or food sticking.</p>

- Q: Is it safe and effective to use aluminum foil with a shiny side facing up to line a baking pan for baking purposes?

- <p>Yes, you can use aluminum foil facing to line a baking pan for baking. The shiny side of the foil, which is the aluminum side, is safe for direct contact with food and can be used to line pans for baking. It helps prevent food from sticking and makes cleanup easier. However, ensure the foil is heavy-duty to withstand high temperatures and does not tear easily. Always follow the manufacturer's guidelines for safe use and avoid overheating, as aluminum foil can melt at very high temperatures.</p>

- Q: This question asks for methods to clean stubborn food residue from the aluminum foil facing of a baking sheet or similar kitchen item.

- <p>To remove stuck-on food from aluminum foil facing, first let the surface cool down. Then, use a plastic scraper or an old credit card to gently lift the residue without scratching the foil. For stubborn stains, make a paste of baking soda and water, apply it to the area, and let it sit for a few minutes before scrubbing. Alternatively, use a mixture of vinegar and water to loosen the food particles. After cleaning, rinse thoroughly and dry to prevent further food adhesion.</p>

- Q: Is it safe to use old aluminum foil for food packaging, considering potential health risks and material degradation?

- <p>Using old aluminum foil for food packaging is not recommended. Over time, aluminum foil can become discolored, thin, or develop pinholes, which can compromise its integrity. These changes can lead to food contamination and the foil's ability to protect food from bacteria or other contaminants. Additionally, old aluminum foil may contain residues from previous uses that could mix with new food items, potentially causing off-flavors or health concerns. It's best to use fresh, clean aluminum foil for food packaging to ensure safety and hygiene.</p>

- Q: Is it possible to repurpose old aluminum foil facing from various items for alternative uses?

- <p>Yes, you can reuse old aluminum foil facing for various purposes. It can be repurposed for crafts, such as creating reflective surfaces or adding texture to art projects. It can also be used in cooking as a makeshift roasting pan liner or to cover dishes to keep them warm. Additionally, aluminum foil facing can be used for insulation, wrapped around pipes to reduce heat loss, or even as a temporary solution for blocking light in greenhouses or windows. Always ensure the foil is clean and in good condition before reusing it for any purpose.</p>

- Q: What are the potential hazards or dangers of using aluminum foil facing in construction or other applications?

- <p>Using aluminum foil facing can pose certain risks, particularly in construction. It may not provide adequate insulation, leading to energy inefficiency. Additionally, it can trap moisture, causing mold or mildew growth and potential structural damage. Aluminum foil facing can also be a fire hazard if it's not properly installed or if it comes into contact with electrical wiring. Moreover, it may not be as durable as other materials, leading to a shorter lifespan and the need for more frequent replacements. It's crucial to consider these factors and consult with professionals when deciding to use aluminum foil facing in any application.</p>

Send your message to us

Aluminum Foil Facing AL-PET Laminated Foil Composite for Shielding Coaxial Cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords