Aluminum Foil Facing Air Condition Duct Film:44mm/50mm/60mm Aluminum Foil with Polyester

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Structure

Widely used for laminating with EPE insulation, Bubble insulation, woven fabric insulation, etc

● Aluminum foil – LDPE

● Aluminum foil- PET- LDPE

● Clear Transparent PET-Aluminum foil – LDPE

● Aluminum foil-Metallized PET- LDPE

● Metallized PET- LDPE

Product Application

Widely used for laminating with EPE insulation, Bubble insulation, woven fabric insulation, etc

Product Advantage

Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• Environmentally friendly, no smell and not-toxic;

• Smooth and clear surface;

Product Packing

1. Waterproof paper then PVC shrinking Film

2. Kraft paper only

3. Woven cloth

4. Kraft paper or Water Proof Film then Metal/wooden pallet

5. (Also as your request. )

Product Remarks

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and kept from wet and heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

Product Data Sheet

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 43.5 | ASTM D646 |

Thickness | mic | 43.2 | ASTM D646 |

Tensile strength: M. D. X. D. | N/15mm | 23.5 23.5 | ASTM D882 |

Delaminating Values | N/15mm | 1.5 | ASTM D904 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -40°C 130°C | No Delamination No Delamination | ASTM C1263 |

Water vapor permanence | ng/N.s | 1.15 | ASTM E-96 |

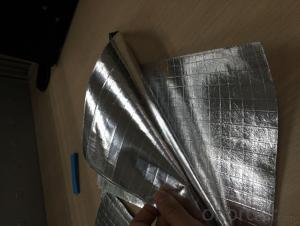

Product Picture

FAQ

1. What is the product keeping conditions?

The Aluminum Foil Facing should be stored at room temperature and kept from wet and heat source.

2. What is the guarantee years of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. What is the delivery time of the order?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: What distinguishes various grades of aluminum foil sheets from one another?

- <p>Different grades of aluminum foil sheets are distinguished by their thickness, strength, and purity. Grade 1 is the purest and softest, used for food wrapping and baking. Grade 2 is harder and more tear-resistant, suitable for heavy-duty use like grilling. Grade 3 is an alloy and offers high strength and durability, often used in industrial applications. Grade 4 is a heat-treatable alloy, providing high strength and used in aerospace and automotive industries. Each grade has specific applications based on its unique properties.</p>

- Q: Explain the distinct features of aluminum foil facing compared to other food covers.

- <p>Aluminum foil facing is a type of food cover that is made from thin sheets of aluminum, known for its high heat conductivity, moisture resistance, and ability to seal in freshness. It's often used for cooking, baking, and preserving food. Other types of food covers include plastic wraps, which are more flexible and cling to food surfaces but may not be as effective at heat conduction or preserving freshness; glass or ceramic lids, which are reusable and provide an airtight seal, but are heavier and not as convenient for single-use applications; and silicone covers, which are heat resistant and can be reused, but may not seal as tightly as aluminum foil.</p>

- Q: What is the function or use of aluminum foil facing in construction or insulation?

- <p>Aluminum foil facing is used primarily for thermal insulation in construction and HVAC systems. It reflects radiant heat, reducing heat transfer and improving energy efficiency. It also serves as a vapor barrier, preventing moisture from passing through insulation, which can reduce its effectiveness. Additionally, aluminum foil facing can provide a clean, finished appearance and protect the insulation material from damage and contamination.</p>

- Q: Is it safe to use old aluminum foil facing as a cutting surface for vegetables and fruits?

- <p>Using old aluminum foil facing as a cutting board is not recommended. Aluminum foil is not designed to withstand the sharp edges of knives and can easily tear or puncture, posing a risk of injury. Additionally, the foil can transfer aluminum particles to the food, which may not be safe for consumption. Instead, use a proper cutting board made from materials like wood, plastic, or bamboo that are designed to handle knives and protect both your food and your safety.</p>

- Q: This question asks for guidance on preparing a nutritious meal using aluminum foil as a cooking method.

- <p>To make a healthy meal using aluminum foil, consider 'foil packet cooking'. Choose lean protein like chicken or fish, and pair it with a variety of colorful vegetables such as bell peppers, zucchini, and cherry tomatoes. Season with herbs, garlic, and a drizzle of olive oil. Fold the foil to create a sealed packet and bake in the oven at 400掳F (200掳C) for about 20-25 minutes or until the protein is cooked through and the vegetables are tender. This method retains nutrients and flavors while minimizing added fats.</p>

- Q: What are the advantages of using food covers made from materials other than traditional ones, specifically regarding health benefits?

- <p>Yes, there are health benefits to using food covers made from alternative materials. For instance, using food covers made from materials like beeswax or silicone can reduce the use of single-use plastic, which is beneficial for both the environment and human health by minimizing exposure to harmful chemicals that can leach from plastic. Additionally, some materials like glass or stainless steel food covers are non-porous and do not retain odors or bacteria, which can help maintain food freshness and safety. Using eco-friendly and reusable food covers can also contribute to a reduction in waste, promoting a healthier planet and, by extension, a healthier lifestyle.</p>

- Q: What are the advantages of using aluminum foil as a reflective surface in various applications, particularly in health contexts?

- <p>Using aluminum foil facing provides several health benefits, particularly in cooking and food preservation. It helps retain moisture in foods, reducing the need for added fats and oils, which can contribute to a healthier diet. Reflective aluminum foil can also help distribute heat evenly in ovens, ensuring food cooks more uniformly and reduces the risk of overcooking or burning. Additionally, it can help in food reheating, ensuring that food is heated evenly and thoroughly, which is important for food safety. In some cases, aluminum foil can also be used to create a barrier against harmful UV rays in tanning beds, although this is not recommended due to potential health risks associated with tanning. Overall, the use of aluminum foil facing can contribute to healthier cooking practices and food safety.</p>

- Q: Is it possible to replace plastic wrap with aluminum foil for food storage in containers?

- <p>Yes, aluminum foil can be used as a substitute for plastic wrap in food storage containers. It effectively seals in freshness and prevents air exposure, which is similar to the function of plastic wrap. However, aluminum foil is not airtight and may not be as effective in preventing the escape of odors or the entry of bacteria as plastic wrap. Additionally, it is not microwave-safe and can be less convenient for re-sealing. It's also important to ensure that the foil does not come into direct contact with acidic or alkaline foods, as this can lead to a reaction and potential contamination.</p>

- Q: Is it safe to use aluminum foil that has been recycled, specifically the foil with a shiny side facing outwards?

- <p>Using recycled aluminum foil facing is generally safe, as long as it meets the standards set by regulatory bodies. Recycled aluminum foil is often used in construction materials and insulation due to its durability and insulation properties. However, it's important to ensure that the recycled foil is free from contaminants and is properly processed. For applications where the foil comes into contact with food or the skin, it's crucial to use foil that has been certified safe for such uses. Always check the manufacturer's guidelines and certifications to ensure safety.</p>

- Q: Can aluminum foil be used as a surface for making pizza crust?

- <p>Yes, you can use aluminum foil facing to make a pizza crust. It's a convenient and non-stick surface that allows the crust to bake evenly and prevents it from sticking. Simply prepare your pizza dough and place it on a piece of aluminum foil sprayed with cooking oil or lined with a silicone mat. Bake according to your pizza recipe, and the aluminum foil will help create a crispy crust.</p>

Send your message to us

Aluminum Foil Facing Air Condition Duct Film:44mm/50mm/60mm Aluminum Foil with Polyester

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords