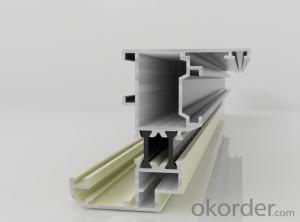

Aluminum Extrusion Standard Profiles for Heat Radiators

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Aluminum profile.heat sink profile

1.Short lead time: 7-15days.

2.professional technology supports.

3.Factory direct price

aluminum profile,industrial aluminum extrusion, construction aluminum profile

Feature:

Specification: according to your aluminum profile drawing or sample

Alloy Code: 6063-T5.6061-T6 o

Surface treatment:

Mill finish

electrophresis

Anodized(silver anodizing,bronze anodizing,champagne anodizing,etc.),

powder coating (need your confirmation by the panton colour, such as RAL9001 )

Length: no more 6.0 M

Sample time: about 13 days o

Lead time:

about 20 days for 1x40' feet

package:

Shrink film and wrapper, kraft paper ,plastic film or per client's requirement.

price: A00(SMM)+Processing fee

payment :

30% deposit +70% before the delivery or against the copy of B/L

delivery : 15-25 days after the deposit confirmed

- Q: Are there any regulations or standards that aluminum profiles must meet?

- Yes, aluminum profiles must meet various regulations and standards. These include ASTM International standards, which provide guidelines for the composition, mechanical properties, and dimensional tolerances of aluminum profiles. Additionally, aluminum profiles may need to comply with specific industry and regional regulations, such as those set by the International Organization for Standardization (ISO) or the European Committee for Standardization (CEN). These regulations and standards ensure the quality, safety, and compatibility of aluminum profiles across different applications and markets.

- Q: Can aluminum profiles be used in exhibition or trade show displays?

- Yes, aluminum profiles can be used in exhibition or trade show displays. Aluminum profiles are lightweight, durable, and versatile, making them an ideal choice for constructing exhibition displays. They can be easily assembled and disassembled, allowing for quick setup and dismantling at trade shows. Additionally, aluminum profiles can be customized to create various shapes and sizes, accommodating different exhibition booth designs. The profiles can also be easily integrated with other materials such as fabric, glass, or acrylic panels to create a visually appealing and professional display. Overall, aluminum profiles offer a cost-effective and practical solution for exhibition or trade show displays.

- Q: This question asks for a list of various aluminum profiles that are utilized in the construction of building facades and cladding systems.

- <p>Aluminum profiles for facades and cladding systems come in various types, each serving specific purposes in construction. Common types include: 1. <strong>Aluminum Extrusions</strong>: Used for structural support and can be customized for specific design requirements. 2. <strong>Aluminum Channels</strong>: Often used for attaching panels or as a part of the support structure. 3. <strong>Aluminum Angles</strong>: Provide corner support and reinforcement. 4. <strong>Aluminum Flat Bars</strong>: Used for horizontal or vertical support in facade systems. 5. <strong>Aluminum Tubes</strong>: Can be used as a decorative element or for structural reinforcement. 6. <strong>Aluminum Louvers</strong>: Designed for sun shading and ventilation. 7. <strong>Aluminum Panels</strong>: Can be flat or profiled, used for the outer layer of the facade. 8. <strong>Aluminum Trims and Mouldings</strong>: Used for finishing and detailing around windows, doors, and edges. Each type is chosen based on the architectural design, structural requirements, and aesthetic preferences.</p>

- Q: What is aluminum profile opening mold, I want to process a batch of aluminum profiles, the other side to open mold fees also expensive, then I can open the mold of things? I don't know the hero for a favor

- There is no on-site mold, so the mold must be re opened to meet the requirements. I hope my answer can help you. Thanks

- Q: This question asks if aluminum profiles can be used in cold weather conditions and if they maintain their properties in such environments.

- <p>Yes, aluminum profiles are suitable for use in cold climates. Aluminum is a durable material with excellent resistance to corrosion and weathering, which includes maintaining its integrity in low temperatures. It does not rust or degrade significantly in cold conditions, making it a reliable choice for construction and other applications in cold climates. However, it's important to consider the specific alloy and any protective coatings or treatments that may be necessary to ensure optimal performance in extreme cold.</p>

- Q: Where is the aluminum profile market in Nanjing? Specific address, bus route

- Before inadvertently arrived, as if on the South Fengtai Road, and now do not know where.

- Q: What are the fire-resistant properties of aluminum profiles?

- Aluminum profiles possess several fire-resistant properties that make them a suitable choice for various applications. First and foremost, aluminum has a high melting point of approximately 660 degrees Celsius (1220 degrees Fahrenheit), which means it can withstand high temperatures without melting or losing its structural integrity. Moreover, aluminum has a low ignition point, meaning it requires a higher temperature to ignite compared to other metals. This property makes it less susceptible to catching fire when exposed to heat or flames. In the event of a fire, aluminum profiles form a protective layer of aluminum oxide on their surface due to their natural oxide layer. This layer acts as a barrier, preventing the further spread of flames and inhibiting the combustion process. Additionally, the aluminum oxide layer is highly heat resistant, providing additional protection against high temperatures. Furthermore, aluminum profiles are non-combustible, meaning they do not contribute to the spread of fire. This characteristic is crucial in fire safety as it helps to contain the fire within a specific area and prevent its rapid expansion. Overall, the fire-resistant properties of aluminum profiles, including high melting point, low ignition point, the formation of a protective oxide layer, and non-combustibility, make them a reliable choice for various applications where fire safety is a concern.

- Q: Are aluminum profiles suitable for use in mining and construction equipment?

- Indeed, mining and construction equipment can benefit from the utilization of aluminum profiles. The unique properties of aluminum make it highly compatible with these industries. Firstly, its lightweight nature aids in reducing the overall weight of the equipment, facilitating easy transportation and maneuverability on construction sites or during mining operations. Moreover, this lightweight characteristic enhances fuel efficiency, thereby decreasing operational costs. Furthermore, aluminum profiles possess exceptional resistance to corrosion, a vital attribute for these industries, where equipment is frequently exposed to severe weather conditions and corrosive substances. This corrosion resistance guarantees the durability and longevity of the equipment, even in challenging environments. Additionally, aluminum profiles offer ease of fabrication and customization to cater to specific requirements. This adaptability in design permits the creation of intricate shapes and structures, enabling the construction of equipment with optimal strength and functionality. Moreover, the high thermal conductivity of aluminum profiles effectively dissipates heat generated during mining and construction operations. This property plays a crucial role in preventing overheating or damage to the equipment, ensuring efficient performance even in intense working conditions. In summary, the combination of lightweight, corrosion resistance, versatility, and thermal conductivity renders aluminum profiles a suitable choice for integration into mining and construction equipment.

- Q: Can aluminum profiles be used for medical equipment or devices?

- Medical equipment or devices can indeed utilize aluminum profiles. The medical industry highly values aluminum due to its unique properties. It possesses a remarkable combination of being lightweight, yet sturdy and long-lasting, which renders it suitable for a wide range of medical applications. The utilization of aluminum profiles enables the production of medical equipment like hospital beds, wheelchairs, surgical tables, and diagnostic equipment. Moreover, aluminum's corrosion resistance makes it an ideal material for medical devices that frequently come into contact with bodily fluids or chemicals. Furthermore, aluminum can be easily sterilized, which is of utmost importance in healthcare settings where maintaining a hygienic environment is crucial. All in all, the utilization of aluminum profiles offers numerous benefits for medical equipment and devices, hence making it a popular choice in the medical industry.

- Q: How do aluminum profiles perform in terms of UV resistance?

- Good UV resistance is typically offered by aluminum profiles. Protection against UV radiation is provided to some extent by the natural oxide layer that forms on the surface of aluminum. However, the UV resistance performance of aluminum profiles can vary depending on factors like the specific alloy used, the quality of surface treatment, and the environmental conditions to which they are exposed. Alloys with higher copper content, such as 6000 series aluminum, generally have better UV resistance compared to pure aluminum or alloys with lower copper content. This is because copper enhances the ability of the natural oxide layer to withstand UV radiation. Proper anodizing or powder coating processes tend to improve the UV resistance of aluminum profiles in terms of surface treatment. Anodizing involves the creation of a thicker and more durable oxide layer on the surface of the aluminum, enhancing its ability to resist UV damage. On the other hand, powder coating involves the application of a protective polymer layer to the aluminum surface, acting as a barrier against UV radiation. The UV resistance of aluminum profiles can also be influenced by environmental conditions. Intense sunlight, high temperatures, and exposure to pollutants or corrosive substances can accelerate the degradation of the oxide layer, thereby reducing overall UV resistance. Regular cleaning and maintenance can help extend the lifespan and UV resistance of aluminum profiles. To summarize, aluminum profiles generally offer good UV resistance due to the presence of a natural oxide layer on the surface. The performance in terms of UV resistance can be influenced by factors such as alloy composition, surface treatment, and environmental conditions. It is advisable to consult manufacturers or suppliers to ensure that the specific aluminum profiles meet the required UV resistance for the intended application.

Send your message to us

Aluminum Extrusion Standard Profiles for Heat Radiators

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords