Aluminum Disc Circle for No-Stick Pans

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Disc Circle Manufacturer for No-stick Pans Description

• Product: Aluminim Circle

• Application: It is used in cookware, engineering, lighting purpose, fried pans, non-sticky pans, cooking pots, kettles, hard anodize cook wire, pressure cooker and house hold utensils, reflector of the light, etc

• Advantage: Deep drawing and hard anodizing quality Aluminum Circle Sheet can be supplied. Our Aluminum Circle is RoHS and REACH compliance and uses well-protected packing. Our circles are excellent material for producing cookware, utensil, pots, pans and kettles.

2.Main Features of the Aluminum Disc Circle Manufacturer for No-stick Pans

• High manufacturing accuracy

• Smooth surface

• No waves

• High strength of extension and yield

• Well packaged

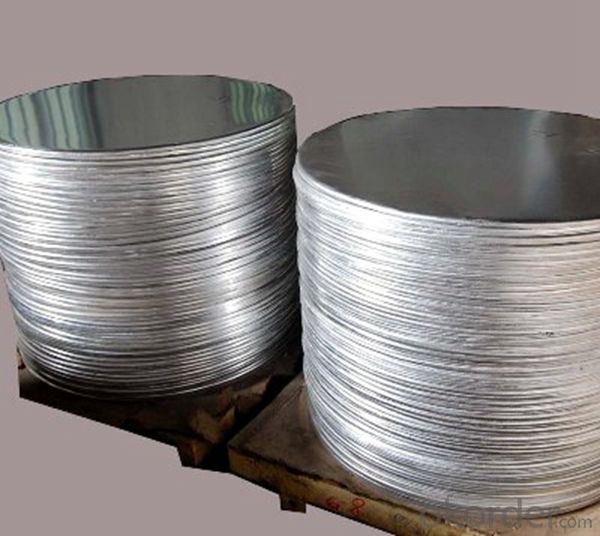

3.Aluminum Disc Circle Manufacturer for No-stick Pans Images

4.Aluminum Disc Circle Manufacturer for No-stick Pans Specification

Alloy | AA1050,AA1060,AA1100 AA3003etc. |

Temper | O,H14 |

Thickness | 0.5MM-4MM |

Diagonal | 100-1200MM |

Standard | GB/T 3880-2006 |

5.FAQ of Aluminum Disc Circle Manufacturer for No-stick Pans

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q: What are some ways aluminum can be used for decoration purposes?

- <p>Aluminum is a versatile material with various decorative uses. It can be used in home furnishings, such as aluminum-framed furniture, mirrors, and lighting fixtures. In architecture, aluminum is utilized for window frames, doors, and decorative facades. Outdoors, aluminum is popular for garden furniture, sculptures, and railings. Its lightweight and corrosion-resistant properties make it ideal for decorative applications in both indoor and outdoor settings. Additionally, aluminum's malleability allows for intricate designs and shapes, making it a popular choice for decorative accents and ornaments.</p>

- Q: This question asks for common applications of aluminum in everyday life.

- <p>Aluminum is widely used in daily life due to its lightweight, durability, and resistance to corrosion. It is commonly found in beverage cans, food packaging, and cookware. Aluminum is also used in construction for window frames, doors, and roofing. It is a key material in the manufacturing of vehicles, including cars, airplanes, and bicycles, due to its strength-to-weight ratio. In electronics, aluminum is used in heat sinks and wiring. Additionally, it is used in everyday items like foil, furniture, and sports equipment. Its versatility makes aluminum an essential material in many aspects of modern life.</p>

- Q: This question asks about the methods used to determine the hardness of aluminum material.

- <p>The hardness of aluminum can be measured using various standardized tests. The most common methods include the Brinell Hardness Test, where a hard steel or carbide ball is pressed into the aluminum surface, and the Vickers Hardness Test, which uses a diamond pyramid indenter. The Rockwell Hardness Test is also used, applying a diamond cone or steel ball to the surface. The hardness is quantified by the depth of the indentation, and the results are expressed in specific hardness units like BHN (Brinell Hardness Number), HV (Vickers Hardness), or HR (Rockwell Hardness). These tests provide a measure of the material's resistance to deformation, which is crucial for applications requiring strength and durability.</p>

- Q: This question asks for examples of alloys that have a significant amount of aluminum and are known for their strength and ductility.

- <p>Alloys that are known for their high aluminum content and possess excellent strength and ductility include 6061 aluminum alloy, 7075 aluminum alloy, and 2024 aluminum alloy. 6061 is widely used in structural applications due to its balance of strength, corrosion resistance, and formability. 7075 is one of the strongest aluminum alloys and is used in aerospace and high-strength applications. 2024 is known for its good mechanical properties and is used in aircraft structures and other demanding applications. These alloys leverage the benefits of aluminum, such as low density and high resistance to corrosion, while their specific compositions and heat treatments enhance their strength and ductility.</p>

- Q: Can the recycling of aluminum be done in a closed loop system without any degradation in the material's quality?

- <p>Yes, aluminum can be recycled using a closed loop process without losing quality. Aluminum is infinitely recyclable, meaning it can be recycled over and over again without losing its properties. The recycling process involves melting the aluminum, which is much less energy-intensive than the original production from raw materials. This closed-loop recycling system helps maintain the quality of aluminum, making it an environmentally friendly and sustainable material.</p>

- Q: What are the methods to prevent aluminum from corroding?

- <p>To prevent aluminum from corroding, several methods can be employed. One effective method is anodizing, which involves applying a protective oxide layer on the aluminum surface to enhance its resistance to corrosion. Another approach is using protective coatings such as paints or enamels that act as a barrier against corrosive elements. Additionally, alloying aluminum with other metals can improve its corrosion resistance. Regular cleaning and maintenance, avoiding contact with corrosive substances, and controlling environmental conditions such as humidity can also help in preventing corrosion.</p>

- Q: This question asks for the distinguishing characteristics of aluminum compared to other metals.

- <p>Aluminum is a lightweight, silvery-white metal that is the most abundant metal in the Earth's crust. It is known for its low density, making it one-third the weight of steel. It is highly malleable, ductile, and has excellent corrosion resistance due to the formation of a protective oxide layer. Unlike many other metals, aluminum is not magnetic and has good thermal conductivity. It is also non-toxic and can be recycled easily. These properties make aluminum distinct from other metals such as iron, copper, and lead, which have different densities, melting points, and chemical reactivities.</p>

- Q: Is there any risk to health from consuming food wrapped in aluminum foil?

- <p>Eating food wrapped in aluminum foil generally does not pose significant health concerns under normal circumstances. Aluminum is a stable element and does not leach easily into food at room temperature. However, at high temperatures, such as during grilling or baking, small amounts of aluminum might migrate into food. Most studies suggest that the amount of aluminum ingested from food wrapped in foil is minimal and not harmful. Nonetheless, it's advisable to avoid wrapping acidic foods or using foil in direct contact with food at high temperatures to minimize any potential exposure.</p>

- Q: Dangemen mills and other Aluminum Alloy and enterprises what is the difference?

- Other aluminium door enterprises cover many other products. This can be said to be the most obvious difference Dangemen factory and other enterprises.

- Q: What are the ecological effects and consequences of producing aluminum?

- <p>The environmental impact of aluminum production is significant and multifaceted. It involves high energy consumption, primarily from the electricity needed for the electrolytic process to extract aluminum from bauxite. This contributes to greenhouse gas emissions, particularly if the electricity is generated from fossil fuels. The process also generates hazardous waste, such as red mud, which contains heavy metals and can pollute water sources if not properly managed. Additionally, deforestation and habitat destruction occur due to bauxite mining, affecting biodiversity. Lastly, aluminum production contributes to air pollution with the release of particulates and other pollutants.</p>

Send your message to us

Aluminum Disc Circle for No-Stick Pans

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords