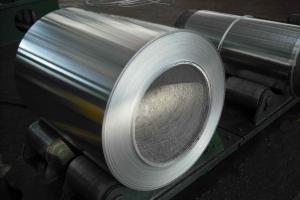

Berger Aluminum Coil - CC Aluminium Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Excellent service

2.Prime quality

3.Cuick delivery

3.ISO 9001:2008

4.BV ,SGS ,

Factory price high quality aluminum coil

Substrates: | Aluminium (1100, 3003, 3004, 3105, 5006, 5052, 8011, etc), etc. |

Thickness: | 0.08-1.5mm |

Width: | <1800mm |

Coils core diameter: | 150mm ,405mm, 505mm, 508mm, 510mm |

Coating thickness: | PVDF >=25micron POLYESTER>=18micron |

Color standard: | E < 2 or it is not obvious by eyeballing |

Pencil hardness: | > 2HB |

Coating adhesive: | not lower than first grade Impact: no any crack (50kg/cm, ASTMD-2794:1993) |

Bend strength: | >100 times |

Boiling point: | no any distortion and color change (in the 99 more or less 1 degree water, then cooling 2 hours) |

Corrosive: | surface deep in the 5% muriatic acid and 5% NaCL, interior deepin the 2% muriatic acid and 2% NaCL, after 48 hours, no change |

- Q: Aluminum metal reacts with hydrochloric acid, HCl, to form hydrogen gas (H2) and a solution of aluminum chloride. Write and balance the equation. Can someone help I just dont get this Al2 + 6HCl → 3H2 + 2AlCl3 Al2 + 2HCl → H2 + 2AlCl 2Al + 6HCl → 3H2 + 2AlCl3 Al + 2HCl → H2 + AlCl2 6Al + 2HCl → H2 + 2Al3Cl

- 2NH4Cl+Ca(OH)2-CaCl+2NH3+2H2O 18 Zn+2Cl-ZnCl2+H2 19 F2+2NaCl-2NaF+Cl2 20 CaO+SO2-CaSO3 21 2CaSO3+O2-2CaSO4 22 2HgO-2Hg+O2 23 CH3OH-CO+2H2 24 2KNO3-2KNO2+O2 you put the question in wrong section. Answer the others by yourself. I have given lots of examples there.

- Q: Can aluminum coils be used in solar panel manufacturing?

- Solar panel manufacturing can incorporate aluminum coils as they are lightweight and durable. This material is widely utilized across industries, including the solar panel manufacturing sector, due to its exceptional thermal conductivity, resistance to corrosion, and cost-effectiveness. In the production of solar panels, aluminum coils are commonly employed to construct the frame or support structure for the photovoltaic cells. By fabricating and shaping the coils to the desired configuration, a robust and steady structure is achieved for the solar panel. Furthermore, aluminum is recyclable, making it an environmentally conscious option for the production of solar panels.

- Q: This question asks for an explanation of the various materials used for coating aluminum coils.

- <p>Aluminum coil coating materials can be categorized into several types, including: 1. Organic coatings, such as polyester, acrylic, and polyvinylidene fluoride (PVDF), which offer good weather resistance and color stability. 2. Inorganic coatings, like fluoropolymers, which provide exceptional chemical resistance and high-temperature stability. 3. Metal coatings, such as zinc or other metals, used for enhanced corrosion resistance. 4. Ceramic coatings, which are known for their high durability and resistance to heat and chemicals. 5. Laminates, which combine multiple materials for specific performance characteristics. These coatings are chosen based on the intended application of the aluminum coil, such as in construction, automotive, or packaging industries.</p>

- Q: Are aluminum coils suitable for food processing applications?

- Yes, aluminum coils are suitable for food processing applications. Aluminum is a versatile and widely used material in the food industry due to its various beneficial properties. It is corrosion-resistant, non-toxic, lightweight, and has excellent thermal conductivity. These properties make aluminum coils ideal for food processing applications such as cooking, storage, and transportation. Aluminum coils can be used in the production of cookware, food packaging, and food processing equipment. They are often used in the manufacturing of pots, pans, baking sheets, and other kitchen utensils. The high thermal conductivity of aluminum ensures even heat distribution, allowing for efficient cooking and preventing hot spots. Furthermore, aluminum coils are commonly used in food packaging, including cans for beverages and canned foods. Aluminum cans are lightweight, durable, and provide a barrier against light, moisture, and air, ensuring the preservation and quality of the food products. In addition, aluminum coils are suitable for food processing equipment such as heat exchangers, evaporators, and refrigeration systems. The corrosion-resistant nature of aluminum prevents contamination and ensures the hygiene and safety of the food being processed. It is important to note that aluminum coils used in food processing applications should meet specific food-grade standards to ensure they do not leach any harmful substances into the food. These standards include regulations set by the Food and Drug Administration (FDA) in the United States and similar organizations worldwide. Overall, aluminum coils are well-suited for food processing applications due to their corrosion resistance, non-toxicity, lightweight, and excellent thermal conductivity. They are widely used in the food industry for cooking, packaging, and processing equipment, contributing to the safety and efficiency of food production.

- Q: Can aluminum coils be customized or fabricated into specific shapes?

- Yes, aluminum coils can be customized or fabricated into specific shapes. Aluminum has excellent formability and can be easily shaped using various fabrication techniques such as rolling, bending, stamping, and extrusion. These processes allow the aluminum coils to be transformed into specific shapes, such as sheets, plates, tubes, and profiles, to meet the specific requirements of different applications. Additionally, aluminum can also be welded, joined, or cut to further customize its shape and size. This versatility in customization makes aluminum coils a preferred choice in various industries, including automotive, aerospace, construction, and manufacturing.

- Q: When the aluminum roll is rolled 0.14, when the coil is taken off, what happened to the loose layer?

- in addition is a kind of expression is down when the aluminum coil suddenly becomes uneven, but the bad effect caused by oil

- Q: What are the various dimensions and specifications of aluminum coils available in the market?

- <p>Aluminum coils come in various sizes and specifications to cater to different industrial needs. Common sizes include thicknesses ranging from 0.005 to 0.5 inches (0.13 to 12.7 mm), widths from 1 to 72 inches (25 to 1829 mm), and lengths from 10 to 6000 feet (3 to 1829 meters). The specific dimensions can vary based on the manufacturer and the application, such as construction, automotive, or packaging. It's important to consult with suppliers for the exact sizes available for a particular project or application.</p>

- Q: What are the different hardness levels of aluminum coils?

- Aluminum coils come in various hardness levels, which are determined by the alloy and tempering process used in their manufacturing. The most common hardness levels for aluminum coils are as follows: 1. Soft (O temper): This state represents the utmost malleability and ductility of aluminum coils. It allows for extensive shaping and bending, making it suitable for applications that require such flexibility. 2. Quarter Hard (H12 temper): In this hardness level, aluminum coils have undergone a slight cold-working process to enhance their strength and stiffness. Although they are less malleable than soft coils, they still possess good formability. 3. Half Hard (H14 temper): Coils in this hardness level have undergone a moderate cold-working process, resulting in increased strength and stiffness. They are less formable than quarter-hard coils but are well-suited for applications requiring higher strength. 4. Three Quarter Hard (H16 temper): Aluminum coils in this hardness level have undergone a more intensive cold-working process, making them even stronger and less formable than half-hard coils. They are appropriate for applications that demand high strength and minimal deformation. 5. Full Hard (H18 temper): Coils in this hardness level have undergone the most extensive cold-working process, resulting in maximum strength and minimal formability. They are commonly employed in applications that prioritize high structural integrity and resistance to deformation. It is important to acknowledge that the specific hardness levels available for aluminum coils may vary based on the alloy and manufacturer. Moreover, different industries and applications may have specific requirements for hardness levels, so it is crucial to select the appropriate hardness level based on the intended use of the aluminum coils.

- Q: Can aluminum coils be used for automotive body panels?

- Yes, aluminum coils can be used for automotive body panels. In fact, aluminum is a popular choice for car manufacturers due to its lightweight and corrosion-resistant properties, leading to improved fuel efficiency and longevity of the vehicle.

- Q: Can aluminum coils be used for solar panel applications?

- Yes, aluminum coils can be used for solar panel applications. Aluminum is a lightweight and durable material that is commonly used in the construction of solar panels. It is an excellent conductor of electricity, making it ideal for capturing and conducting solar energy. Aluminum coils can be used as a backing material for solar panels, providing structural support and helping to dissipate heat. Additionally, aluminum has good corrosion resistance, which is important for solar panels that are exposed to various weather conditions. Overall, aluminum coils are a popular choice for solar panel applications due to their strength, conductivity, and resistance to corrosion.

Send your message to us

Berger Aluminum Coil - CC Aluminium Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords