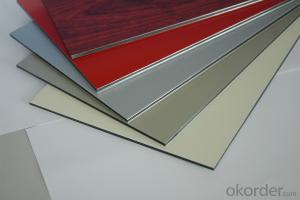

Aluminum Composite Panel for Exterior Cladding and Interior Wall Decoration

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Aluminium Composite Panel for exterior cladding and interior wall decoration

1.Coating: PVDF/PE

2.Core: unbreakable/ breakable LDPE core

3.ISO9001:2000 and SGS certificate

1. Standard:

according to GB/T 17748-1999 standard

2. Material:

a) Front: aluminum alloy sheet coated with fluoro-carbon resin

(PVDF) and polyester resin (PE) roasting painting

b) Core: nontoxic polyethylene.

c) Back: aluminum alloy sheet coated with polyester resin painting

d) Surface finish: treated with PVDF and PE resin rolling roasting .

coating

e) Surface coating thickness: 30um

f ) Aluminum alloy sheet thickness: 0.1mm, 0.12mm, 0.15mm, 0.2mm,

0.3mm, 0.4mm, 0.45mm, 0.5mm

3. Dimensions:

a) Thickness: 3mm, 4mm

b) Width: 1220mm 1500mm..

c) Length: 2440mm, 3200mm, 4000mm,5000mm (max: 6 meter)

d) Weight: 5.5kg/sqm based on 4mm thickness.

e) Standard size: 1220 x 2440mm

f) Nonstandard sizes are available according to requirement of customers

4. Application scope of aluminium composite panel for exterior cladding and interior wall decoration

1) Building exterior curtain walls..

2) Decoration and renovation additions for old buildings

3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies

4) Shop door decorations

5) Advertisement board display platforms and signboards

6) Wallboards and ceilings for tunnels..

Packaging: Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers. Pallet weight: Max. 2.30 tons.

Shipment: the goods will be delivered in 40 days after getting the buyer's payment.

Repeat rolling - Cleaning - Pretreatment – Coating - Inspection - Film production - Plastic extruding – Compositing - Packing

- Q: Is it safe or permissible to use aluminum in food packaging materials?

- <p>Yes, aluminum is commonly used in food packaging due to its lightweight, durability, and excellent barrier properties against air, moisture, and light. It is used in various forms such as aluminum foil, cans, and flexible packaging materials. However, it's important to ensure that the aluminum packaging is food-grade and complies with safety regulations to prevent any potential health risks associated with aluminum exposure.</p>

- Q: This question asks about the health effects of consuming aluminum on human health.

- <p>Aluminum consumption can have various effects on human health, though the extent of its impact is still a subject of debate among researchers. High levels of aluminum intake have been associated with neurological disorders, particularly Alzheimer's disease, although a direct causal link has not been definitively established. Aluminum can also interfere with bone health, potentially leading to osteoporosis, and may affect the kidneys, causing dysfunction. It is important to note that the human body naturally excretes aluminum, so moderate exposure is generally not harmful. However, excessive intake, especially over a long period, could pose health risks.</p>

- Q: Explain the impact of aluminum on manufacturing processes in a few sentences.

- <p>The use of aluminum significantly affects manufacturing processes by offering several advantages. It is lightweight, which reduces the weight of products and can lead to fuel efficiency in transportation sectors. Aluminum's high strength-to-weight ratio makes it ideal for structural components. Its excellent thermal and electrical conductivity allows for efficient heat dissipation and electrical transmission. Additionally, aluminum is non-magnetic and non-corrosive, which is beneficial for certain applications. The metal is also easily recyclable, contributing to sustainability in manufacturing. These properties make aluminum a popular choice in industries such as automotive, aerospace, construction, and electronics, enhancing the efficiency and performance of manufacturing processes.</p>

- Q: Explain how the strength of aluminum is affected by temperature changes.

- <p>The strength of aluminum decreases with increasing temperature. As temperature rises, aluminum undergoes thermal expansion, which can lead to a reduction in its yield strength and tensile strength. This is because the increased thermal energy causes the aluminum atoms to vibrate more, weakening the metallic bonds. At very high temperatures, aluminum can become ductile and may even lose its structural integrity. Conversely, at very low temperatures, aluminum can become brittle, which also affects its strength negatively. Therefore, the optimal temperature for maintaining the strength of aluminum is typically within its normal operating range.</p>

- Q: Is there an alternative method for recycling aluminum besides the conventional recycling process?

- <p>Yes, aluminum can be recycled in different ways. Apart from the conventional recycling process, which involves melting and recasting, there are innovative methods being explored. One such method is mechanical recycling, where aluminum is cleaned, sorted, and processed into new products without melting. Another approach is chemical recycling, which breaks down aluminum into its constituent elements and then reassembles them into new materials. These alternative methods aim to reduce energy consumption and environmental impact while still effectively recycling aluminum.</p>

- Q: This question asks for an explanation of the steps involved in producing aluminum.

- <p>The production process of aluminum primarily involves two stages: extraction from bauxite and refining. Initially, bauxite ore, the primary source of aluminum, is mined and then processed to remove impurities. The refined bauxite is then mixed with a hot caustic soda solution in a process called the Bayer Process, which extracts aluminum oxide (alumina). In the second stage, alumina is dissolved in molten cryolite and subjected to an electrolytic reduction process in a Hall-H茅roult cell. This involves passing an electric current through the molten mixture, causing the aluminum oxide to decompose and release pure aluminum, which collects at the bottom of the cell. The aluminum is then tapped off, cooled, and cast into various forms for further processing or use.</p>

- Q: This question asks about the impact of aluminum on human health, including potential effects and health concerns.

- <p>Aluminum is a common element that can be found in various forms in the environment. While it is not considered an essential nutrient for the human body, it can be ingested through food, water, and medications. In small amounts, aluminum is generally considered safe and is excreted by the body. However, excessive exposure or intake can lead to potential health concerns. Aluminum has been linked to neurological disorders, particularly Alzheimer's disease, although the exact relationship is still a subject of debate. It can also cause bone disorders and affect kidney function. The human body has mechanisms to regulate aluminum levels, but individuals with impaired kidney function may be at a higher risk of aluminum toxicity.</p>

- Q: Is aluminum a suitable material for use in space exploration?

- <p>Yes, aluminum is indeed used in space exploration. It is valued for its lightweight properties, which are crucial for reducing the mass of spacecraft and payloads. Additionally, aluminum has good thermal conductivity and can withstand extreme temperature variations, making it suitable for various components in spacecraft. It is also resistant to corrosion and has high reflectivity, which can be beneficial for heat management and communication systems. However, its low strength-to-weight ratio compared to some other materials like titanium or advanced composites means it is often used in combination with other materials or for specific applications where its properties are advantageous.</p>

- Q: This question asks for a list of typical flaws or imperfections that can occur in aluminum products.

- <p>Common defects in aluminum products include porosity, which refers to small holes or voids within the material; surface defects such as scratches, dents, and discoloration; mechanical defects like warping or deformation; and metallurgical defects such as inclusions or impurities. Additionally, aluminum products can suffer from corrosion, which can lead to pitting or general surface degradation, and stress corrosion cracking, which occurs under certain environmental conditions and stress. Each of these defects can impact the structural integrity, appearance, or performance of aluminum products.</p>

- Q: Is it possible to enhance the efficiency of solar panels by utilizing aluminum?

- <p>Yes, aluminum can be used to improve the efficiency of solar panels. Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity, which can help in dissipating heat and maintaining optimal operating temperatures for solar cells. It is also used in the manufacturing of solar panel frames, providing structural support while reducing the overall weight of the panels. Additionally, some research suggests that using aluminum in the backsheet of solar panels can enhance their durability and efficiency. However, the extent of efficiency improvement depends on various factors, including the specific design and manufacturing process of the solar panels.</p>

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 1996 |

| Annual Output Value | Above US$200 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Composite Panel for Exterior Cladding and Interior Wall Decoration

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords