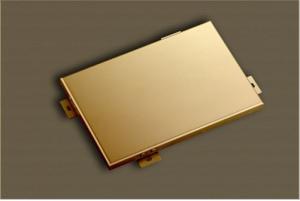

Aluminum composite panel for exterior/interior cladding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 900 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Model Number:FD-ACP-03

MOQ:300 Sheets

FOB Price: US$ 3 - US$ 18

FOB Port:China (Mainland)

Lead Time: 5 - 15 days

Payment Terms:Letter of Credit (LC, L/C)

Country of Origin:China (mainland)

Specifications:

Thickness: 2-8mm

Width: 1,000-2,500mm

PVDF: 20 years (PPG paint)

Core: unbreakable, fire-proof A2

With green leaf, CE mark

Materials:

Front: aluminum alloy sheet coated with polychromatic PVDF paint on surface

Core: non-toxic low-density polyethylene

Back: aluminum alloy sheet coated with polyester resin painting

- Q: Aluminum plate and plastic plate prices, the more detailed the better, thank you

- Thickness 4 mm, aluminum thickness 0.21 + 0.21 mm, 280 yuan / Zhang,

- Q: We decorated with aluminum-plastic plate with what? Lvkou Ban and aluminum-plastic plate prices compared to how ah, which better look? Which better care ah, simply a few words on the line

- Aluminum-plastic board is generally used for wall decoration, aluminum slab plate is generally a bathroom, kitchen ceiling with ah, the price is relatively cheap.

- Q: Aluminum-plastic curtain wall construction in winter, with the real paste can you?

- Another winter weather should also be divided into regions, such as the winter of winter and winter in Hainan,

- Q: Yueyang where to buy aluminum-plastic plate, which the market has aluminum-plastic plate sales

- December Xunyi mechanical and electrical market part of the shops opened, when the major hardware and mechanical have. Now you can go to the sun bridge big market or Dongting Building.

- Q: Standard for aluminum-plastic plates

- Aluminum-plastic plate standard GB / T17748-2008 "building curtain wall with aluminum composite panel" for the external wall panels, the general application of more than 4mm sheet.

- Q: OKorder aluminum-plastic plate how much money, a little better, do with the external walls

- Good at about 85 yuan a

- Q: All kinds of sheet prices, professionals know? To detail the point (wood core board, Jiuli mix, decorative panels, aluminum panels, fire board, etc.), sincere thanks

- Jinan Magnetite Magnesite Fireproof Plate (glass magnesium plate) is a stable magnesium gelling material as the base material, with alkali glass fiber cloth as a reinforcing material, made of lightweight materials, Decorative materials. It is widely used in high-rise residential, hotel, office, commercial shopping center, laboratory, factory, activity room, hospital, railway station, dance hall and so on. It is widely used in high-rise residential, Partition wall and ceiling decoration.

- Q: Sub-white aluminum-plastic door with a white aluminum side, how? The effect is good?

- The easiest way is to directly on the white aluminum-plastic plate directly attached to a layer of black aluminum plate. Since you have done aluminum-plastic board layer, that grass-roots flatness should not be a problem! We often do shop strokes, spray paint with the car, will not fall, the premise is to clean up the original level, remember that is spray, not brush.

- Q: Are there any differences between aluminum slabs and aluminum panels?

- Aluminum plate is pure aluminum, mainly used for ceiling. Aluminum-plastic board full name of aluminum-plastic composite panels, use more widely.

- Q: What plastic glue can stick with the board?

- Omnipotent can be, some say that special glue, in fact, almost the same ingredients.

Send your message to us

Aluminum composite panel for exterior/interior cladding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 900 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords