Aluminum Coils for Air Conditioners - Aaluminum Foil Induction Seal Liner for HDPE and PET Packers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Details: | Standard export packing or following customer's demand |

Delivery Detail: | Within 10-20days or according to the order quantity |

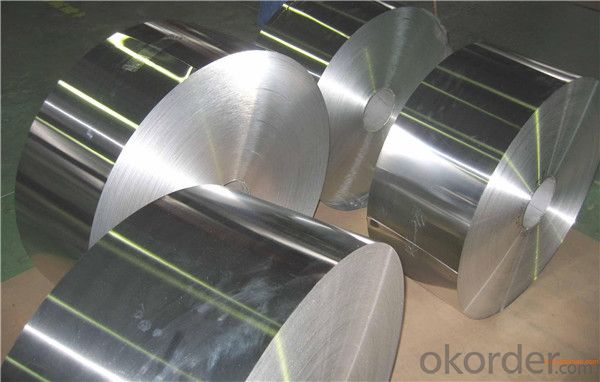

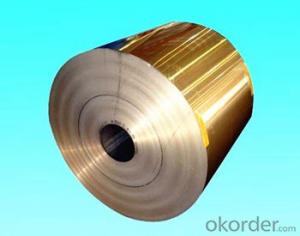

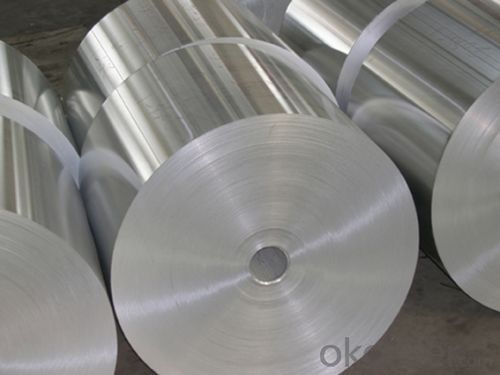

High Quality and Factory Price Aluminum Coil

Specifications

Grade

| 1000 Series: 1050 1060 1070 1100 1200 1235 etc. 3000 Series: 3003 3004 3005 3104 3105 3A21 etc. 5000 Series: 5005 5052 5083 5086 5154 5182 5251 5754 etc. 6000 Series: 6061 6063 6082 6A02 etc. 8000 Series: 8006 8011 8079 etc. |

Thickness | 0.05~10mm |

Width | <1600mm< span=""> |

Color | Metallic, Solid, RAL or by customer requirements |

Coating paint: | PVDF(Polyvinylidene Fluoride), PE(Polyester ) |

Coating thickness | as per customer’s request |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | Polyester18~27micron(EN ISO-2360:1995) PVDF27 ~35micron(EN ISO-2360:1995) |

Coating hardness | 2H |

Protective film | PVC film, Colorless transparent or White-black |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

Temper | H16, H18, H24, H26, H26 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 2000kgs |

Payment | L/C ,T/T |

Specifications | Width: 30cm,38cm,45cm, OEM; Length: 3m-20m, OEM; Thickness: 10mic-20mic(10mic=10um=0.01mm), OEM; Sizes can be customized according to your requirement; |

| Application |

Supermarkets, catering, hotel, airline, restaurants, household, medical,electronic,chocolate wrapping etc;

|

| Characteristic | 1. Use: suitable for the food packing, barbecue; 2. Color: for food only do sliver color; 3. Inner packing : paper roll core; 4. Box with metal cutter; 5. Surface packing: Color box; |

| NOTES | Our factory can quote to you at the specifications that what you want any time. To undertake all kinds of plastic processing operations. Any sizes and packing can be ordered. Good service and reasonable price.

|

FAQ

1. How can I get some samples?

We are honored to offer you samples. New clients are expected to pay for the courier cost. The samples are free for you.

2 Do you have any certificates?

Our products passed inspection of SGS, FDA, and CE Quality is priority! Every worker keeps the QC from the very beginning to the very end, Quality control department especially responsible for quality checking in each process.

3 Can your factory print or emboss my logo on the goods?

Yes, we can print or emboss the logo on the goods or their packing box.

4 What information should I let you know if I want to get a quotation?

1) The specification of products (length x width x thickness);

2) The temper and alloy.

3) The final product you will use to be made

4 It will be better if you can show us the pictures or design sketch. Samples will be best for clarifying. If not, we will recommend relevant products with details for reference.We usually produce goods based on customers

Samples or based on customers’ picture, logo, sizes etc.

Our Services

1. Reasonable production arrangement to make delivery very fast;

2. We are able to provide leading tolerances, metallurgical assistance, quick and reliable delivery, samples for new products, etc.

3. We have the strong capability to meet your particular requirement for the products.

4.To guarantee the quality of the products we can meet most of the standards all over the world.

Photos

- Q: What are the different grades of aluminum used in coil production?

- The different grades of aluminum used in coil production typically include 1100, 3003, and 5052. These grades vary in terms of their composition and properties, allowing for specific applications and requirements in various industries.

- Q: What is the maximum width of aluminum coils?

- The maximum width of aluminum coils is subject to variation based on several factors, including the manufacturing process, the specific grade and type of aluminum, and the capabilities of the equipment employed. Nevertheless, in broad terms, the maximum width of aluminum coils can span from a few inches to multiple feet. Industrial coil lines ordinarily possess the capacity to handle widths up to 72 inches, whereas specialized machinery might be capable of accommodating even wider coils. To ascertain the precise maximum width applicable to a specific application, it is crucial to consult with the manufacturer or supplier.

- Q: How do aluminum coils contribute to recyclability in the construction industry?

- Aluminum coils play a crucial role in enhancing recyclability in the construction industry due to their inherent properties and characteristics. Firstly, aluminum is a highly recyclable material, meaning it can be recycled repeatedly without losing its quality or physical properties. This makes aluminum coils a sustainable and eco-friendly choice for construction projects. The recyclability of aluminum coils helps reduce the environmental impact associated with the construction industry. By choosing aluminum coils, construction companies can contribute to the conservation of natural resources and the reduction of energy consumption. Recycling aluminum requires significantly less energy than producing it from raw materials, resulting in a substantial reduction in greenhouse gas emissions and carbon footprint. Moreover, the use of aluminum coils in construction facilitates the dismantling and deconstruction processes, making it easier to separate the aluminum components from other materials. This efficient separation allows for the effective recycling of aluminum coils, ensuring that they can be transformed into new products or materials. Additionally, aluminum's durability and resistance to corrosion make it a suitable choice for construction applications. Its long lifespan reduces the need for frequent replacements, further minimizing waste generation and the consumption of raw materials. When the time comes to replace or renovate a building, the aluminum coils can be easily collected, recycled, and reintroduced into the manufacturing cycle, closing the loop of the material's lifecycle. In summary, aluminum coils significantly contribute to recyclability in the construction industry. Their high recyclability, low energy requirements for recycling, and ease of separation during deconstruction make them an environmentally friendly choice. By utilizing aluminum coils, the construction industry can promote sustainability, reduce waste generation, and conserve natural resources, ultimately leading to a greener and more circular construction sector.

- Q: I was wondering if you could mold clay into a sphere then fill it with aluminum. Then put it over a fire and wait until the aluminum melts then put it in a freezer and it would come out as a sturdy, aluminum sphere. Thanks!

- Do not try this at home! Seriously, this is exactly the kind of process that is used for casting metals. However, you need to have very strong molds with no cracks in them. Also, aluminum presents special problems. Solid aluminum does not corrode the way iron does, because it very quickly forms a protective tough layer of aluminum oxide. But molten aluminum can catch fire, with devastating consequences.

- Q: Are aluminum coils suitable for construction purposes?

- <p>Yes, aluminum coils can be used for construction. They are valued for their lightweight, corrosion resistance, and high strength-to-weight ratio, making them ideal for applications such as roofing, facades, and structural components. Aluminum's malleability allows for easy shaping and forming, which is beneficial in various construction projects. It's also sustainable due to its recyclability, reducing environmental impact.</p>

- Q: What is the common color of aluminum coil membrane?

- The blue transparent membrane is the most common.

- Q: What is the density of aluminum coils?

- The density of aluminum coils typically ranges from 2.6 to 2.8 grams per cubic centimeter.

- Q: How do aluminum coils contribute to the reduction of carbon footprint?

- Aluminum coils contribute to the reduction of carbon footprint by being lightweight, durable, and recyclable. Their lightweight property reduces fuel consumption during transportation, resulting in lower greenhouse gas emissions. Additionally, aluminum coils have a longer lifespan and require less maintenance, reducing the need for frequent replacements and associated carbon emissions. Finally, aluminum is highly recyclable, meaning that when coils reach their end of life, they can be easily recycled into new products, further reducing the carbon footprint associated with their production.

- Q: Are aluminum coils suitable for beverage can manufacturing?

- Yes, aluminum coils are suitable for beverage can manufacturing. Aluminum is a preferred material for beverage cans due to its various advantageous properties. Firstly, aluminum is lightweight, which makes it easy to transport and handle. This is particularly important for the beverage industry, where large quantities of cans are produced and distributed. Additionally, aluminum is highly malleable, allowing it to be formed into the desired shape without losing its structural integrity. This makes it ideal for can manufacturing, as it can be easily shaped into a can's cylindrical form and withstand the pressure from carbonated beverages. Moreover, aluminum is a non-toxic material, ensuring that it does not contaminate the beverages stored in the cans. It also provides a barrier against light, oxygen, and moisture, which helps to preserve the taste and quality of the beverages. Furthermore, aluminum is recyclable, making it an environmentally friendly choice for can manufacturing. The recycling process for aluminum requires significantly less energy compared to producing new aluminum, making it a sustainable material option. Overall, the suitability of aluminum coils for beverage can manufacturing is evident due to its lightweight nature, malleability, non-toxicity, preservation properties, and recyclability.

- Q: What benefits can utilizing aluminum coil bring to the construction industry?

- <p>Aluminum coil offers several advantages in construction, including its lightweight nature which reduces structural load and facilitates easier handling and installation. It is highly resistant to corrosion, ensuring longevity and low maintenance costs. The material is also known for its excellent thermal conductivity, making it suitable for energy-efficient applications. Additionally, aluminum coil is recyclable, contributing to sustainability and reducing environmental impact. Its versatility allows for various applications, from roofing and siding to structural components, enhancing aesthetic appeal and functionality.</p>

Send your message to us

Aluminum Coils for Air Conditioners - Aaluminum Foil Induction Seal Liner for HDPE and PET Packers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords