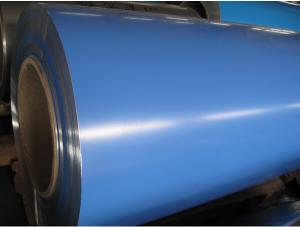

2024 Aluminum Coil with PE Film on the Main Side

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Aluminum Coil with PE Film on the Main Side

Aluminium is a relatively soft, durable, lightweight,ductile and malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible light and an excellent reflector(as much as 98%) of medium and far infrared radiation. The yield strengthof pure aluminium is 7–11 MPa, while aluminium alloys have yield strengthsranging from 200 MPa to 600 MPa. Aluminium has about one-third the density and stiffness of steel.It is easily machined, cast, drawnand extruded.

Aluminum coil/sheet have been used in the field of construcction and decoration(garage doors,ceiling etc.),electronic appliances,lignting decoration, air-condition air pipes,sandwichpanels and drainages etc.

2.Main Features of theAluminum Coil with PE Film on the Main Side:

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Well packaged

• No marks, no scratch, no excessive oil

3. Package of Aluminum Coil with PE Film on the Main Side

4.FAQ

1. What is the form of payment?

Normally 30% TT, L/C

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Shanghai port

4. Delivery time?

35 day after client’s deposit

5 Our Advantages

1. Excellent quality of products

2. Quick delivery

3. Best service to clients

4. BV,SGS avalible

5. No buckle o waveness

6. Tension leveling

7. Certificate of Origin

8. FormeA,E

- Q: I bought some drain opener as a source of sodium hydroxide and it has little silvery balls in it which I believe are aluminium. How can I separate the two substances with minimal loss of the sodium hydroxide? I don't care about the aluminium.

- Trust me. Its not worth salvaging the hydroxide. Aluminum hydroxide is unbelievably stable and that means you probably won't be able to salvage the hydroxide without doing electrolysis or something difficult like that. That's like trying to obtain hydroxide from methanol CH3OH. Oh yea you can make methanol quite easily from a halomethane by reacting it with a hydroxide of some kind. But you will not be able to remove that hydroxide at all without neutralizing it with an acid. Hydroxides are bloody awful leaving groups. That oxygen is really glued on to that carbon well. You have to really destabilize that methanol to remove that hydroxide. Same with the aluminum hydroxide. Very stable and strong bond.

- Q: What is the maximum width-to-thickness ratio for aluminum coils?

- The maximum width-to-thickness ratio for aluminum coils is influenced by various factors, including the specific alloy, temper, and intended application. Industries like construction, automotive, and packaging commonly employ aluminum coils, which may necessitate different width-to-thickness ratios. Typically, the width-to-thickness ratio for aluminum coils ranges from 100:1 to 200:1. However, it is crucial to recognize that this range can fluctuate depending on the specific alloy and temper. Thicker coils generally possess a lower width-to-thickness ratio, while thinner coils may have a higher ratio. High-strength alloys, particularly those utilized in aerospace applications, typically exhibit lower width-to-thickness ratios due to their heightened strength requirements. Conversely, coils used in less demanding applications might have higher width-to-thickness ratios. To determine the appropriate width-to-thickness ratio for a specific aluminum coil, it is essential to consult relevant industry standards, specifications, or manufacturer guidelines. These guidelines take into account the intended use, mechanical properties, and performance requirements, ensuring that the coil is suitable for its intended application while maintaining structural integrity and functionality.

- Q: What is the average lifespan of an aluminum coil?

- The lifespan of an aluminum coil can differ depending on several factors, including the quality of the aluminum, the environment it encounters, and the level of maintenance and care it receives. Generally, aluminum coils are known for being durable and having a long lifespan. Typically, a properly installed and well-maintained aluminum coil can endure for 15 to 30 years. However, it is essential to note that this is merely an average estimation, and some coils may last even longer if properly cared for. Various elements can impact the longevity of an aluminum coil, such as exposure to severe weather conditions like extreme heat, cold, or humidity, as well as exposure to corrosive substances or chemicals. Consistently cleaning and maintaining the coil, including the removal of debris and addressing any signs of damage or wear, can also assist in extending its lifespan. To summarize, the average lifespan of an aluminum coil usually ranges from 15 to 30 years, but it is crucial to consider multiple factors that can influence its durability. Regular maintenance and appropriate care can significantly prolong the lifespan of an aluminum coil.

- Q: Is it possible to utilize aluminum coils in the construction of solar panels or wind turbines?

- <p>Aluminum coils can be used in the construction of both solar panels and wind turbines, but not as the primary material for energy conversion. In solar panels, aluminum is often used for framing and mounting structures due to its lightweight and corrosion-resistant properties. For wind turbines, aluminum is utilized in the manufacturing of certain components such as nacelle shells and towers, but the main rotor blades are typically made from composite materials for their strength and aerodynamic properties. Thus, while aluminum plays a supportive role in these renewable energy technologies, it is not the core material for capturing solar or wind energy.</p>

- Q: What style of womens Oakley sunglasses come in aluminum? I need a tough pair and would like interchangeable lenses option also.

- There are several in aluminum, but do not meet your criteria of interchangeable lenses. The LIV and the Crosshair S are both aluminum, but they do not have interchangable lenses (in the case of the LIV, in the case of the Crosshair S, the lens swap takes a bit of work and replacement lenses are not readily available). If you can, go with one of the unisex styles that are titanium. Oakley O-luminum (Oakley's special Aluminum Alloy) bends rather easily and doesn't return very well. I have 6 pairs of Crosshair sunglasses (the larger size, not the S), so I can attest to the nature of O-luminum. X-metal glasses are what you should be looking at. X-metal is Oakley's proprietary blend of Titanium alloy and are extremely durable. The Juliet and the X- Squared are the current models. Replacement lenses are readily available AND they're fairly easy to swap out (you'll need T6 screwdriver). The titanium frames are super tough. Juliet's fit medium faces. X-squared fit medium/large faces. If you're looking for a great combination of durability, light weight, and interchangeable lenses that change with no tool- look at the Flak Jacket. They are unisex, as are all the Oakley glasses that are not marked women's. Although they look like plastic, these are not. They are made from O-Matter This is a nylon based material that is flexible and allows glasses like the Flak Jacket to be run over by steam roller and still be worn. Lenses swap out in less than 30 seconds and there are a ton of colors to choose from. These are from the sport line. HTH D

- Q: When the aluminum roll is rolled 0.14, when the coil is taken off, what happened to the loose layer?

- I think the 0.14mm is certainly not the aluminum coil lining sleeve forgot, then the biggest doubt is the oil removal effect is not good, with rolling after the aluminum layer between the leakage for aluminium roll support is not enough, the collapse of the volume, the specific performance is the edge of the circular aluminum layer was uniform into ripples;

- Q: I would like to order 25 micron diameter 99.99% Aluminum wire required to use for making electrical connections. Only several cm are needed, so I would like to purchase a small spool. Delivery ASAP preferable (overnight or two day shipping would be best). This wire will be attached by hand using epoxy and not using a wire bonder.

- If they can't help, try asking the tech support guys at the wirebond manufacturers and the tool manufacturers. KS in the US and Shinkawa in Japan used to be the big guys. You can search for ultrasonic bond tools. You can also check with superconducting research centers; several private and public ones. Researchers might loan you materials and/or bonding support. BTW, Al critical temp is reportedly about 1.2°K, pretty tough to get that cold! U/S bond wire has 1% silicon, partly for hardness, you can probably bond pure wire though. Key is breaking up the oxide. Maybe bonding at cold temps and/or in vacuum would work. Also, I doubt epoxy would be good or superconducting at the temps. Al filled epoxy is unreliable electrical conductor due to oxide formation. Will be a bear to handle such fine wires without a bonder! Good luck!

- Q: Are aluminum coils suitable for automotive applications?

- Yes, aluminum coils are suitable for automotive applications. Aluminum coils offer several advantages such as lightweight, high corrosion resistance, and excellent heat conductivity, making them an ideal choice for various automotive components like radiators, condensers, and evaporators. The use of aluminum coils helps improve fuel efficiency, reduce emissions, and enhance overall vehicle performance.

- Q: ... of aluminum atoms?(mole = 6.022x10^23)

- WHEN IM OUT ON THE SEA WITH ME CREW I LIKE TO THINK THAT PERHAPSY WE CAN LOOT A BARGE FULL 'O THAT WONDROUS MATERIAL YE CALL ALUMINUM AS FER MOLES, THEY CAN BE QUITE THE PESTS AROUND YER GARDEN AND WHAT-NOT

- Q: I have heard that aluminum may be a contributing agent in causing Alzheimer's disease, and that if we drink from aluminum cans, that we get aluminum into our system from them. It seems like this would be pretty easy to test in a laboratory, whether or not there are aluminum particles in the contained beverage. But I have heard or read that the inside of the cans are coated with something. So is this just typical uninformed rumors from the Internets, or is there anything to it? Hate to sound rude, but I am not really interested in opinions, like Well I don't think they would sell them if... or Oh yes, I think you get lots of aluminum from it. I am only interested in facts, not gut feelings or opinions.

- As mentioned, there is a coating on the inside of the can that prevents the drink from coming into contact with the can. You won't be getting any aluminum, HOWEVER in that coating is a chemical called BPA. This chemical has been shown to affect the body's hormonal systems and can affect the birth of future children, even if one is not presently pregnant. It has recently been declared a toxic substance in Canada and other countries seem to be slowly following suit in declaring it as such. This chemical is used because it is cheap. Governments tend to be very hesitant banning things that are harmful if they affect the way corporations can make money. I try to avoid cans for this very reason. When you drink from them you'll be getting trace amounts of this chemical. Trace amounts over time add up in the body, especially with this chemical.

Send your message to us

2024 Aluminum Coil with PE Film on the Main Side

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords