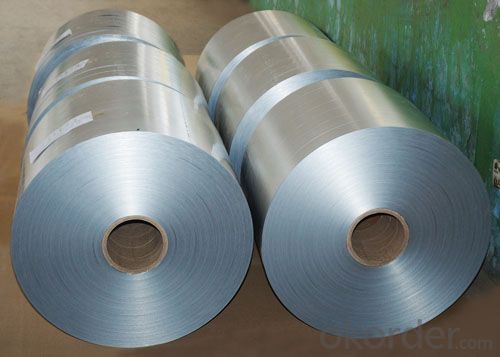

Aluminum Coil Home Depot Lowe's 0.3mm-4.0mm 1100 H14 Aluminium Hardness Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Grade:

1000 Series,7000 Series,3000 Series

Surface Treatment:

Coated,Embossed,Anodized,Mill Finish,Color Coated,Oxidized,Enameled Wire

Shape:

Angle,T-Profile,Flat,Rectangular

Temper:

O-H112,T351-T851,Half Hard

Application:

Decorations,Transportation Tools,Glass Wall,Kitchen Use

Technique:

DC/CC

Thickness:

0.05-4.0mm

Width:

900--1500mm

Outer Diameter:

450-600

Net Weight (kg):

2.5 ton

Packaging:

Wooden pallets

0.3mm-4.0mm 1100 H14 Aluminium Hardness Coils

Packaging & Delivery

Product Specification | |

Grade | 1000 Series: 1050 1060 1100 3000 Series: 3003 3004 3105 5000 Series: 5052 5605,5083 6000 Series: 6061 6063 8000 Series: 8011 8021 8079 |

Thickness | 0.20-8.00mm |

Width | 2400mm max. |

Grade | 1000,3000,5000,6000,8000series |

Coil ID | 75mm, 150mm, 200mm, 300mm, 400mm, 508mm or negotiable |

Coil weight | 1000-5000kgs |

Coil OD | 1700mm max. |

Temper | O, H12, H14, H16, H111, H22 ,H24, H26, H28,T4, T6,etc. |

| Temper | |

| F | processing state |

| H | strain hardening state |

| O | annealing |

| T | heat treatment state |

| H112 | pure state of strain hardening, adjustment has been made to degree of strain hardening and annealing |

| T4 | solid solution treatment and natural efficiency to achieve sufficient stability condition |

| T5 | artificial aging condition of the reentry after high temperature thermal cooling |

| T6 | artificial aging state after solid solution treatment |

Chemical Composition | |||||||||

| Grade | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Al |

| 1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | - | - | 0.05 | 99.5 |

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | - | 0.05 | 99.6 |

| 1070 | 0.2 | 0.25 | 0.04 | 0.03 | 0.03 | - | - | 0.04 | 99.7 |

| 1100 | Si+Fe:0.95 | 0.05-0.2 | 0.05 | - | - | 0.1 | - | 99 | |

| 1200 | Si+Fe:1.00 | 0.05 | 0.05 | - | - | 0.1 | 0.05 | 99 | |

| 1235 | Si+Fe:0.65 | 0.05 | 0.05 | 0.05 | - | 0.1 | 0.06 | 99.35 | |

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | - | - | 0.1 | remains |

| 3004 | 0.3 | 0.7 | 0.25 | 1.0-1.5 | 0.8-1.3 | - | - | 0.25 | remains |

| 3005 | 0.6 | 0.7 | 0.25 | 1.0-1.5 | 0.20-0.6 | 0.1 | - | 0.25 | remains |

| 3105 | 0.6 | 0.7 | 0.3 | 0.30-0.8 | 0.20-0.8 | 0.2 | - | 0.4 | remains |

| 3A21 | 0.6 | 0.7 | 0.2 | 1.0-1.6 | 0.05 | - | - | 0.1 | remains |

| 5005 | 0.3 | 0.7 | 0.2 | 0.2 | 0.50-1.1 | 0.1 | - | 0.25 | remains |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | - | 0.1 | remains |

| 5083 | 0.4 | 0.4 | 0.1 | 0.40-1.0 | 4.0-4.9 | 0.05-0.25 | - | 0.25 | remains |

| 5154 | 0.25 | 0.4 | 0.1 | 0.1 | 3.1-3.9 | 0.15-0.35 | - | 0.2 | remains |

| 5182 | 0.2 | 0.35 | 0.15 | 0.20-0.50 | 4.0-5.0 | 0.1 | - | 0.25 | remains |

| 5251 | 0.4 | 0.5 | 0.15 | 0.1-0.5 | 1.7-2.4 | 0.15 | - | 0.15 | remains |

| 5754 | 0.4 | 0.4 | 0.1 | 0.5 | 2.6-3.6 | 0.3 | - | 0.2 | remains |

| 6061 | 0.40-0.8 | 0.7 | 0.15-0.40 | 0.15 | 0.8-1.2 | 0.04-0.35 | - | 0.25 | remains |

| 6063 | 0.20-0.6 | 0.35 | 0.1 | 0.1 | 0.45-0.9 | 0.1 | - | 0.1 | remains |

| 6082 | 0.7-1.3 | 0.5 | 0.1 | 0.40-1.0 | 0.6-1.2 | 0.25 | - | 0.2 | remains |

| 6A02 | 0.50-1.2 | 0.5 | 0.20-0.6 | Or Cr0.15-0.35 | 0.45-0.9 | - | - | 0.2 | remains |

| 8011 | 0.50-0.9 | 0.6-1.0 | 0.1 | 0.2 | 0.05 | 0.05 | - | 0.1 | remains |

- Q: Can aluminum coils be customized to specific requirements?

- Indeed, specific requirements can be accommodated through customization of aluminum coils. The versatility of aluminum coils allows for a broad range of specifications and applications to be met. Customization options encompass alloy selection, coil thickness, width, and length, as well as diverse surface treatments like coatings, finishes, and embossing. Furthermore, mechanical properties such as strength, flexibility, and corrosion resistance can be tailored to individual needs. To achieve desired outcomes, close collaboration with manufacturers or suppliers possessing the necessary expertise and facilities is necessary. Whether for the aerospace industry, automotive sector, construction projects, or any other usage, aluminum coils can be tailor-made to fulfill specific requirements and deliver optimal performance.

- Q: What are the different coil packaging sizes available for aluminum coils?

- The different coil packaging sizes available for aluminum coils vary depending on the manufacturer and industry requirements. Common coil packaging sizes for aluminum coils range from small coils with diameters as small as 150mm to larger coils with diameters exceeding 1000mm. The coil widths can also vary, typically ranging from 100mm to 1500mm. However, it is important to note that specific coil packaging sizes may differ based on customer specifications and the intended application of the aluminum coils.

- Q: What is the typical heat transfer coefficient for aluminum coils?

- The typical heat transfer coefficient for aluminum coils can vary depending on various factors such as the specific application, coil design, and operating conditions. However, a commonly observed range for the heat transfer coefficient of aluminum coils is around 50 to 250 W/m2K.

- Q: What are the different surface treatments for aluminum coils?

- There are several different surface treatments available for aluminum coils, each offering unique properties and benefits. Some common surface treatments for aluminum coils include: 1. Mill Finish: This is the untreated, raw surface of aluminum coils that comes directly from the mill. It has a slightly rough texture and is typically used in applications where aesthetics are not a primary concern. 2. Anodized Finish: Anodizing is an electrochemical process that creates a protective layer on the surface of the aluminum coil. This treatment enhances corrosion resistance, improves durability, and provides a wide range of color options. 3. Painted Finish: Aluminum coils can be coated with various paint systems to enhance their appearance and protect against corrosion. Painted finishes offer a wide range of colors, gloss levels, and textures, allowing for customization according to specific design requirements. 4. Polished Finish: Polishing is a mechanical process that creates a smooth and reflective surface on the aluminum coil. This treatment is often used in decorative applications, where a high-quality and aesthetically pleasing finish is desired. 5. Brushed Finish: Brushing involves mechanically brushing the surface of the aluminum coil to create a pattern of fine parallel lines. This treatment provides a unique texture and is commonly used in architectural and interior design applications. 6. Embossed Finish: Embossing is a process of creating raised or recessed patterns on the surface of the aluminum coil. This treatment adds texture, enhances strength, and can be used for decorative purposes or to improve grip in certain applications. 7. Laminated Finish: Lamination involves applying a layer of protective film or coating on the surface of the aluminum coil. This treatment provides additional protection against scratches, abrasion, and UV rays, making it suitable for outdoor applications. Each surface treatment option has its own advantages and is chosen based on the specific requirements of the application, such as corrosion resistance, durability, aesthetics, and functionality.

- Q: If you were to make something from each of these.which is more expensive? aluminum or carbon fiber ?which is stronger?What would the advantages or disadvantages of each be?

- Aluminum Vs Carbon Fiber

- Q: Hello, I'd like to ask you a question. Can the aluminum coil be continuously pressed and cooled by kerosene?

- Yes, water and oil are not miscible. They must be emulsified

- Q: Can aluminum coils be used in the production of railway tracks?

- No, aluminum coils cannot be used in the production of railway tracks. Railway tracks are typically made of steel due to its strength, durability, and ability to withstand heavy loads and high temperatures. Aluminum, although lightweight, lacks the necessary strength and toughness required for railway track applications.

- Q: Can aluminum coils be used in electrical or electronic applications?

- Yes, aluminum coils can be used in electrical or electronic applications. Aluminum is a good conductor of electricity and has excellent thermal conductivity, making it suitable for various electrical and electronic components such as transformers, inductors, and motors. Additionally, aluminum coils are lightweight, cost-effective, and have good corrosion resistance, making them a popular choice in these applications.

- Q: im doing an a level physics presentation on aluminium and im trying to compare aluminium and copper in electricity pylons.i know that copper will have a better conductance than aluminium becasue it has a lower resitivity but i need to come up with a calculation to prove why aluminium is better for use in electricity pylons? i know its down to aluminium being more lightweight than copper and also much cheaper. But im not sure how to create an calculation to show this?:) any help is greatly appreciated

- Copper has lower resistance per unit volume, ie, a 1 cm diameter copper wire has less resistance than a 1 cm aluminum wire. BUT, aluminum is much lighter than Cu for the same diameter. If you used an aluminum wire that weighs the same as the 1 cm diameter copper wire, it would have LOWER resistance. And that is why aluminum is used in power transmission, and also in aircraft, where weight is important. to do this you calculate density resistivity which is (resistivity x density). Here is a partial table: Al 28.2e-9 Ω-m * 2700 kg/m? = 76e-6 Ω-kg/m? Cu 17.2e-9 Ω-m * 8960 kg/m? = 154e-6 Ω-kg/m? Ag 15.9e-9 Ω-m * 10500 kg/m? = 167e-6 Ω-kg/m? Au 22.14e-9 Ω-m * 19300 kg/m? = 427e-6 Ω-kg/m? Zn 68e-9 Ω-m * 7130 kg/m? = 485-6 Ω-kg/m? Fe 100e-9 Ω-m * 7870 kg/m? = 787e-6 Ω-kg/m? Note that Al is half that of Cu.

- Q: I need ideas on soundproofing a 12' aluminum fishing boat?

- The ULTIMATE way to soundproof and line your boat is with that stuff they cover the bed of pick-up trucks. Cabelas sells a kit you paint on. It works great! Call Cabelas, it's only $50, and it works and looks professional!

Send your message to us

Aluminum Coil Home Depot Lowe's 0.3mm-4.0mm 1100 H14 Aluminium Hardness Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords