Alloy Aluminum Coil 3000 Series Cold Rolled Aluminum Coils 1050 1060 1100

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Cold rolled aluminum coils 1050 1060 1100

Thickness | 0.1mm-10mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm... |

Width | 20mm-2500mm |

inner diameter | 505mm 508mm 605mm |

Material | 1050,1060,1070,1100,1200,3003,3004,3005,5052,5005,5754,5083 |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38,H111,H112 |

Surface | mill finish |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 15-25 days after receiving L/C or deposit |

Remark | Specific requirement of alloy grade, temper or specification can be discussed at your request |

2. Application of Cold rolled aluminum coils 1050 1060 1100

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Cold rolled aluminum coils 1050 1060 1100

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

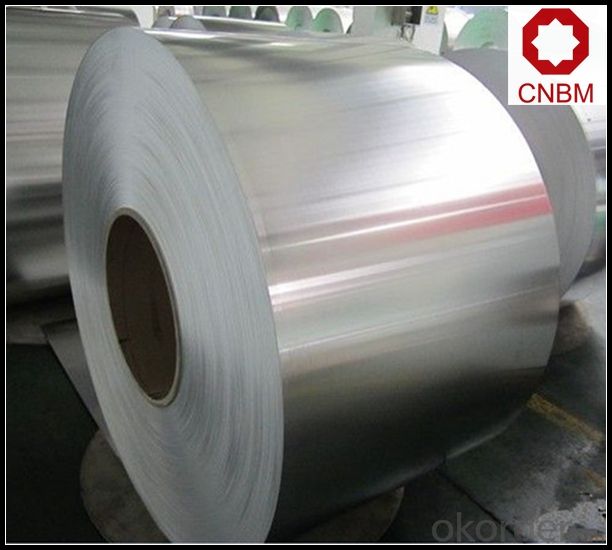

5. Image of Cold rolled aluminum coils 1050 1060 1100

6. Package and shipping of Cold rolled aluminum coils 1050 1060 1100

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are aluminum coils suitable for decorative applications?

- Yes, aluminum coils are suitable for decorative applications. Aluminum is a versatile and lightweight material that offers excellent corrosion resistance, making it an ideal choice for decorative purposes. It can be easily shaped, formed, and fabricated into various designs, patterns, and finishes, allowing for endless possibilities in decorative applications. Additionally, aluminum coils can be coated with different colors and finishes, such as anodized or painted, to enhance their aesthetic appeal and durability. Whether it's for interior or exterior decoration, aluminum coils provide a cost-effective and visually appealing solution.

- Q: Are aluminum coils suitable for architectural facades?

- Yes, aluminum coils are suitable for architectural facades. They are lightweight, durable, corrosion resistant, and can be easily formed into various shapes and sizes. Additionally, aluminum coils offer a wide range of finishes and colors, making them a versatile choice for architectural facades.

- Q: How do aluminum coils contribute to sustainable construction?

- Due to their numerous environmental benefits, aluminum coils play a vital role in promoting sustainable construction practices. One key advantage is the high recyclability of aluminum, with almost 75% of all aluminum ever produced still in use today. This means that at the end of their lifespan, aluminum coils can be easily recycled, reducing the need for new raw materials and minimizing waste sent to landfills. Furthermore, compared to other materials like steel, the production process of aluminum coils requires significantly less energy. This results in a low carbon footprint, as the energy consumed during production is considerably lower, leading to fewer greenhouse gas emissions. Additionally, the reduced energy consumption contributes to lower operating costs for construction projects, making aluminum coils an economically viable choice. Moreover, aluminum coils are not only lightweight but also highly durable, making them an ideal option for sustainable construction. Their lightweight nature reduces the need for heavy support structures, which in turn reduces material consumption and transportation costs. Additionally, the durability of aluminum coils ensures a longer lifespan, reducing the frequency of replacement and minimizing waste generation. Another crucial aspect of aluminum coils in sustainable construction is their excellent corrosion resistance. This resistance means that structures made from aluminum coils require less maintenance and repair over time. Consequently, fewer resources are needed to uphold the building's integrity, resulting in a reduced overall environmental impact. In conclusion, aluminum coils contribute significantly to sustainable construction through their high recyclability, energy efficiency, lightweight yet durable nature, and excellent corrosion resistance. By opting for aluminum coils, construction projects can significantly decrease their environmental footprint, conserve resources, and advocate for a more sustainable built environment.

- Q: Why the end of the aluminum coil will have a yellow spot?

- The reason may be that the manufacturer is not cleaned, and must be carefully cleaned before coating, or there may be paint fall off phenomenon.

- Q: Are aluminum coils easy to install?

- Aluminum coils, in general, prove to be easily installed. Their lightweight and flexibility contribute to their manageable handling and maneuverability during installation. They can be effortlessly cut and molded to suit the precise installation requirements. Moreover, they are frequently obtainable in pre-cut dimensions, further streamlining the installation procedure. Additionally, aluminum coils usually incorporate interlocking edges or snap-on connectors, facilitating the connection of multiple coils or other components. All in all, with appropriate tools and fundamental HVAC installation knowledge, aluminum coils can be readily installed.

- Q: The general roll also 5,6t appearance, specific to your own weigh, length, weight = / (width * thickness * density)

- Oh, landlord, this question is a little interestingIf it is the embryo of the aluminum plant, the aluminum roll is usually 5-6 tons a rollFor a while, in the merchant or the direct manufacturer, it is necessary to see how large the material rack is in the factory. It is usually 1.5-2 tons, and there are also three tons.Yes, please!

- Q: Can aluminum coils be used in vacuum applications?

- Yes, aluminum coils can be used in vacuum applications. Aluminum is a commonly used material in vacuum systems due to its excellent properties such as low outgassing, high thermal conductivity, and good corrosion resistance. These properties make aluminum coils suitable for various vacuum applications, including but not limited to, vacuum chambers, vacuum pumps, cryogenic systems, and particle accelerators. However, it is important to note that aluminum can be reactive with certain gases or chemicals, so it is essential to consider the specific requirements and compatibility of the vacuum application before using aluminum coils.

- Q: What are the various surface finishes available for aluminum coils?

- Aluminum coils offer a variety of surface finishes to meet different needs and preferences. The options include: 1. Mill Finish: This is the most basic and natural finish achieved by passing the coil through rollers during manufacturing. It gives the aluminum a smooth, shiny appearance. 2. Anodized Finish: Anodizing is an electrochemical process that adds a protective layer to the aluminum coil's surface. It comes in various colors and provides enhanced resistance to corrosion, abrasion, and wear. Architects commonly use anodized finishes. 3. Painted Finish: Aesthetic appeal and environmental protection can be achieved by coating aluminum coils with paint. The paint comes in different colors and finishes, such as matte, glossy, or metallic. 4. Brushed Finish: By brushing the surface with abrasive materials, aluminum coils can have a textured appearance with fine lines or scratches. Brushed finishes are often used for decorative purposes. 5. Polished Finish: Buffing the surface of the aluminum coil creates a smooth, reflective finish. It gives a mirror-like appearance and is commonly used for decorative and architectural applications. 6. Embossed Finish: Embossing involves stamping or pressing a pattern or design onto the surface of the aluminum coil. This finish adds texture and depth, making it suitable for non-slip surfaces or decorative purposes. 7. Laminated Finish: Lamination involves bonding a thin layer of film or foil to the aluminum coil's surface. This finish provides additional protection against scratches, stains, or UV radiation. It is commonly used for applications that require durability and resistance. These examples highlight the range of surface finishes available for aluminum coils. The choice of finish depends on specific application requirements, desired appearance, and functional properties needed for the end product.

- Q: Are there any limitations on the length of aluminum coils?

- Yes, there are limitations on the length of aluminum coils. The length of aluminum coils is typically limited by practical considerations, such as transportation and handling capabilities. Additionally, longer coils may become more susceptible to bending, warping, or other forms of damage. Consequently, manufacturers often have specific maximum length specifications for aluminum coils.

- Q: actually pollute more than the process of extracting it from earth and producing new aluminum?I saw a report about 5 years ago on this and was wondering if anyone else had info on this subject.

- Much less smelting required to convert pure aluminum into aluminum ingots than is needed to process boxite(?) into aluminum ingots.

Send your message to us

Alloy Aluminum Coil 3000 Series Cold Rolled Aluminum Coils 1050 1060 1100

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords