Aluminum Coil Car Brushed Coated Aluminum Coils for Metal Wall ACP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Brushed Coated Aluminium Coils for Metal Wall ACP Description

• Product: Aluminim coils

• Application:

corrugated roofs, outer walls, ovens, electrically controlled cabinets.

household appliances, transportation, base plate, color coating.

industrial freezers in the residential and industrial buildings.

refrigerator backplane, gas stove, air conditioner, microwave, LCD border.

• Advantage: Full production line with all kinds of coils supply

2. Main Features of the Brushed Coated Aluminium Coils for Metal Wall ACP

• Our goods quality is top, the surface is smooth, and every steel coil

• No Joint, No Bends, no spots, no roller marks.

• MTC will be provided with goods, third part inspection is acceptable, for example, SGS, BV. Etc

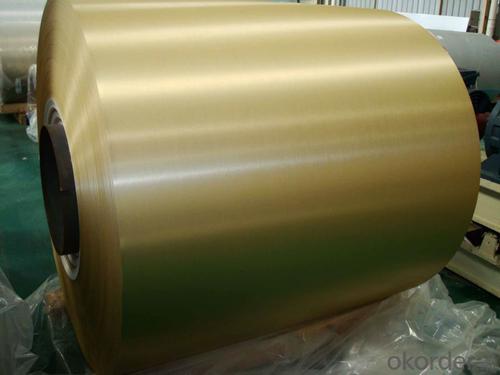

3. Brushed Coated Aluminium Coils for Metal Wall ACP Images

4. Brushed Coated Aluminium Coils for Metal Wall ACP Specification

Alloy | AA1050/1100/3003/3005/3105/5005/5052 etc |

Thickness | 0.03mm—4.0mm |

Width | 10mm—1600mm |

Coating | PVDF, PE |

Coatingthickness | Usually16-25 micron, could be 33-40 micron |

Color | According to Ral |

Standard | ASTM-B 209 GB/3008-2006 |

Usage/ApplicationsCoated Aluminum Coil/Sheet | Constructionand decoration, electronic appliances, lighting decoration, air-condition airpipe, sandwich panels and drainage, etc |

5.FAQ of Brushed Coated Aluminium Coils for Metal Wall ACP

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q: Can aluminum coils be used for heat transfer applications?

- Indeed, heat transfer applications can utilize aluminum coils. The commendable thermal conductivity of aluminum renders it remarkably efficient in transferring heat. In multiple heat transfer applications like air conditioning systems, refrigeration units, and heat exchangers, aluminum coils are frequently employed. The lightweight nature of aluminum, coupled with its resistance to corrosion, further contributes to its widespread preference in these applications. Moreover, the malleability of aluminum coils allows for the facile shaping and forming, thereby facilitating efficient heat transfer even in intricate systems.

- Q: Which is better composite or aluminum, and what are some main differences between the two?

- There are great bats that are made out of each, but I generally tend to think that composite bats have better performance. There are aluminum bats that may be better than a given composite, but generally a high-end composite will be better than a high-end aluminum. Composites tend to have larger sweet spots, some span the entire length of the barrel, and the ball will still travel well if hit towards the outside of the sweet spot. contact hitters should look towards composites, because their slower swings will be compensated for with the spring action of the composite material. I think aluminums are better for power hitters because that material has been used for decades and the weight distribution has been better perfected for harder swings.

- Q: What are the compositions of aluminum coil coating?

- The common compositions are crylic resin, solid inorganic filler, different pigments, flatting agent and so on.

- Q: This question asks about potential safety hazards when using electric heaters that have aluminum coils.

- <p>While electric heaters with aluminum coils are generally safe when used properly, there are some safety concerns to consider. Aluminum can heat up quickly and may become very hot, posing a risk of burns if touched. Additionally, aluminum coils can corrode over time, potentially leading to electrical shorts or fires. It's important to ensure that the heater is not covered or obstructed, as this can cause overheating. Always follow the manufacturer's instructions for use and safety precautions. Regularly inspect the heater for any signs of damage or wear, and never use a heater with a damaged cord or plug.</p>

- Q: Can aluminum coils be used in building facades?

- Yes, aluminum coils can be used in building facades. Aluminum is a popular material choice for building facades due to its numerous benefits. It is lightweight, durable, and corrosion-resistant, making it suitable for exterior applications. Aluminum coils can be formed into various shapes and sizes, allowing for creative and versatile design possibilities. Additionally, aluminum is available in a wide range of finishes, including anodized, painted, and coated, providing further customization options for building facades. Moreover, aluminum is a sustainable material as it is 100% recyclable, making it an environmentally friendly choice for construction projects. Overall, aluminum coils are a viable option for building facades, providing both aesthetic appeal and functional performance.

- Q: Are aluminum coils resistant to UV rays?

- Yes, aluminum coils are resistant to UV rays.

- Q: How do aluminum coils perform in extreme weather conditions?

- Aluminum coils are renowned for their outstanding performance in challenging weather conditions. With their inherent properties, aluminum coils exhibit remarkable resistance to corrosion, rendering them ideal for usage in areas with high humidity, coastal regions, and locations susceptible to acid rain or industrial pollution. Furthermore, aluminum coils possess a high melting point, enabling them to endure extreme heat without warping or distorting. In frigid weather, aluminum coils demonstrate exceptional durability and do not become brittle like some alternative materials. They maintain their structural integrity, ensuring optimal performance even in freezing temperatures. Additionally, aluminum coils possess excellent thermal conductivity, enhancing their efficiency in heat transfer and defrosting capabilities, crucial for HVAC systems operating in cold weather conditions. In hot and humid climates, aluminum coils excel in resisting corrosion, preventing moisture accumulation, and sustaining their efficiency. Crafted to withstand high humidity levels, they prevent the growth of mold or bacteria that could compromise indoor air quality. Moreover, the lightweight nature of aluminum coils aids in dissipating heat rapidly, improving overall cooling performance and energy efficiency. Furthermore, aluminum coils exhibit remarkable durability and can endure extreme weather events, including hurricanes, strong winds, and hailstorms. Engineered to be robust and impact-resistant, they withstand harsh weather conditions without sustaining damage. Overall, aluminum coils have proven their reliability and effectiveness in extreme weather conditions, delivering long-lasting performance and durability. Their corrosion resistance, ability to withstand high and low temperatures, and capacity to endure severe weather events make them an excellent choice for diverse applications, such as HVAC systems, refrigeration units, and outdoor equipment.

- Q: Can aluminum coils be used for HVAC ducting?

- Yes, aluminum coils can be used for HVAC ducting. Aluminum is a common material used in HVAC systems due to its durability, lightweight nature, and resistance to corrosion. Aluminum coils are often used to manufacture HVAC ductwork as they can effectively distribute air throughout the system while maintaining its structural integrity. Additionally, aluminum coils are highly efficient in transferring heat, allowing for more efficient cooling and heating processes within the HVAC system. Overall, aluminum coils are a suitable choice for HVAC ducting due to their numerous benefits and ability to meet the requirements of a well-functioning HVAC system.

- Q: What are the common safety precautions when working with aluminum coils?

- Some common safety precautions when working with aluminum coils include wearing personal protective equipment such as gloves, safety glasses, and appropriate clothing to protect against cuts and burns. It is important to handle the coils with care to prevent injury, as they can be heavy and have sharp edges. Additionally, workers should be cautious when operating machinery or tools around the coils to avoid accidents. Proper ventilation should be ensured in the work area to prevent the buildup of fumes or dust. Lastly, workers should be trained on proper lifting techniques and be aware of the potential hazards associated with working with aluminum coils.

- Q: This is not for around the house. It is for my lab. I am pretty sure these one wires are Aluminum, but I need the connector they were made with and the power cable is copper. Would it be okay to still try to join the two.

- yes but use wire nuts

Send your message to us

Aluminum Coil Car Brushed Coated Aluminum Coils for Metal Wall ACP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords